Alcohol Fuels: Options for Developing Countries

advertisement

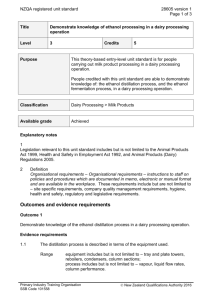

Vacuum Fermentation Studies on vacuum fermentation have been conducted in Great Britain, the United States, and elsewhere. Work by the W. S. Atkins Group at Manchester University has centered on reducing energy use and fermentation time through vacuum fermentation of concentrated sub strafes with high yeast levels. Substrates such as molasses and sac charified cassava are fed directly to the fermenter, and a portion of the fermenting mass is recirculated through a flash separator to remove alcohol as it is formed. Figure 19. Profile view of the experimental unit showing the flow patterns maintained during fermentation. (E. Wick) Figure 20. Continuous fermentation system. (K. Rosen) Work on vacuum fermentation by Ramalingham and Finn at Cornell University indicates that a threefold higher sugar concentration can be fermented in one-third of the time needed in a conventional process. Preliminary process studies by Cysewski and Wilke at the University of California indicate that ethanol plant capital costs for vacuum operation may be reduced up to 71 percent over batch processing. Extractive Fermentation 49 Rolz at ICAITI (Guatemala) has developed an extractive fermentation system based on sugarcane. In this process, whole cane from the fields is cleaned and cut, with the foliage retained for fuel use. The cane is then chipped and placed in a fermenter, where water and yeast are added. The sucrose from the cane is extracted and fermented simultaneously in the same equipment. When the fermentation is finished, the extracted chips are separated and the solution is charged to a batch of fresh chips. After this second fermentation, the solution (containing about 5 percent ethanol) is distilled to recover the alcohol. Alcohol Recovery In examining the energy consumption of alternative recovery systems, Vergara has summarized the status and efficiency of several approaches as shown in Table 8. Other possibilities for low-energy alcohol recovery include the use of reverse osmosis, molecular sieves, solvent extraction, and supercritical carbon dioxide. In studies comparing these techniques at Battelle Pacific Northwest Laboratories (USA), a solvent extraction method looks most promising. In this process, a proprietary solvent mixture is contacted with the ethanol-water mix derived from fermentation and extracts the ethanol. This is done under slight pressure, so that when the pressure is subsequently reduced, the bulk of the solvent flashes off and is recovered for reuse. Battelle also examined a carbon dioxide extraction process developed by Arthur D. Little (USA) in which liquid CO2 is used to extract ethanol and then depressurized to flash off the CO2. Results of these tests are compared with other conventional and nonconventional techniques in Table 9. TABLE 8 Energy Efficiency of Alternative Distillation Systems System Live steam Energy Used Status (kg steam/ liter alcohol) 4.5-5.0 Commercial Reboiler, feed preheating, optimization 3.5 Commercial 3.7 Pilot 3.6 Pilot 1.6 Laboratory Atmospheric distillation, CaO dehydration 1.3 Laboratory Vacuum fermentation, atmospheric distillation Differential pressure fermentation, atmospheric distillation Differential pressure fermentation, vacuum distillation Atmospheric distillation, cellulose dehydration 1.0 50 Laboratory An alternative to the final distillation step used to produce anhydrous alcohol has been examined by Maiorella at the University of California. Using the process developed by the Mobil Oil Corporation for the conversion of methanol to gasoline, 85 percent ethanol is first partially converted to ethylene and ethyl ether and then catatyfically converted to a synthetic gasoline. The reactions and conceptual design are shown in Figures 21 and 22. By-Product Recovery and Waste Treatment The principal by-products in ethanol production are carbon dioxide, fusel oils, and stillage. Carbon Dioxide This gas is produced during the fermentation step and is usually vented to the atmosphere. In most cases, recovery of carbon dioxide and its compression for use as a solid refrigerant ("dry ice") or use in promoting growth in controlled environment agriculture (greenhouses) is uneconomic: about 575 kg of carbon dioxide are produced for each 1,000 liters of ethanol. TABLE 9 Energy Requirements of Ethanol Separation Processes Ethanol (%) Energy Type of Separation Initial Final Complete Process 10 100 Conventional distillation Needed Btu/gal) 27,400a 10 100 CO2 extraction 8,00010,000b To azeotrope Azeotropic to complete 10 100 Solvent extraction 3,600 10 100 Vacuum distillation 37,000c 10 95 Conventional distillation 18,000 10 95 Vapor recompression 6,400b 10 95 Multi-effect vacuum 7,200d 95 100 Conventional distillation 9,400 95 100 Dehydration by adsorption 1,200e 95 100 Low-temperature gasoline blending 3,000f 95 100 Molecular sieve 4,7006,270 Other 5 10 Reverse osmosis 51 500 a Sum of distillation to azeotrope and azeotropic distillation Thermal energy required for process mechanical energy c Single-column distillation d Three-column distillation e For drying with CaO f Azeotrope blended with gasoline and cooled to - 30° C SOURCE: Battelle-Northwest, Richland, Washington, USA. b Figure 21. Ethanol can be converted to gasoline components by a route similar to one used for methanol to gasoline. (B. Maiorella) Figure 22. Conceptual design of a two-stage system to convert ethanol to gasoline hydrocarbons. (B. Maiorella) 52