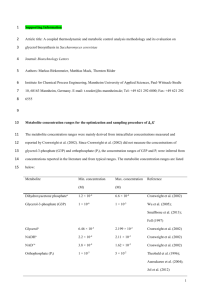

Calculation of the scaled flux control coefficients with larger ranges

advertisement

Supporting Information Thermodynamic and probabilistic metabolic control analysis of riboflavin (vitamin B2) biosynthesis in bacteria Journal: Applied Biochemistry and Biotechnology Markus Birkenmeier, Matthias Mack, Thorsten Röder Institute for Chemical Process Engineering, Mannheim University of Applied Sciences, Paul-Wittsack-Straße 10, 68163 Mannheim, Germany. E-mail: t.roeder@hs-mannheim.de; Tel: +49 621 292 6800; Fax: +49 621 292 6555 Generating thermodynamically feasible combinations of the transformed Gibbs energies of the reactions by a two-step sampling procedure In the first step, we generated a set of standard transformed Gibbs energies of the reactions 𝚫 𝐫 𝐆′𝟎 within the following ranges: 𝚫 𝐫 𝐆′𝟎 − 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 ≤ 𝚫𝐫 𝐆′𝟎 ≤ 𝚫𝐫 𝐆′𝟎 + 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 (S1) For this operation, we used the MATLAB function rand. By repeating the whole two-step sampling sequence 1500 times, this function sampled the standard transformed Gibbs energies of the reactions in a uniform distribution over the ranges (Eq. (S1)). In the second step, we used the generated 𝚫𝐫 𝐆′𝟎 and sampled the metabolite concentrations in their constrained logarithmic space [1]. This sampling was performed with the ACHR sampler within the MATLAB function cprnd (implemented by Benham [2] based on Kaufman and Smith [3]). For compatibility with the ACHR sampler, we formulated the sampling task as 𝐍 𝐓 ∙ ln(𝐜) < − 𝚫𝐫 𝐆′𝟎 𝑅∙𝑇 ln(𝐜𝐦𝐢𝐧 ) < ln(𝐜) < ln(𝐜𝐦𝐚𝐱 ) (S2) (S3) The algorithm samples the natural logarithms of the metabolite concentrations over their restricted ranges [see Eq. (S3)]. For each generated 𝚫𝐫 𝐆′𝟎 in the first step, we sampled 1500 sets of logarithmic metabolite concentrations in the second step. 1 In summary, the whole two-step procedure was repeated 1500 times to give 2.25 × 106 (1500 × 1500) thermodynamically feasible 𝚫 𝐫 𝐆′ vectors (see Fig. 4 in the main text). Calculation of scaled elasticity values using a sampling approach As described in the main text, we uniformly sampled the degrees of saturation of the active sites and calculated the scaled metabolite concentrations, as suggested by Wang et al. [4]. In general, the degree of saturation of an active site 𝜎A is defined as [1, 4] 𝜎A = [AS] [AT ] = [S] 𝐾M [S] +1 𝐾M with [AT ] = [A] + [AS] (S4) where 𝜎A is the quotient of the concentration of the active site–substrate complex [AS] and the total concentration of the active site [AT ] ([A] is the concentration of the free active site). To obtain the scaled metabolite concentration [S] 𝐾M , Eq. (S4) can be rearranged as [S] 𝐾M = 𝜎A 1−𝜎A (S5) By uniformly sampling the degree of saturation of an active site 𝜎𝐴 between 0 and 1 (𝜎A ≈ 0, approximately non-saturated, 𝜎A ≈ 1 , nearly fully saturated), random independent samples of the scaled metabolite concentration [S]/𝐾M can be obtained [1, 4]. The uniform sampling of the degrees of saturation of the active sites was performed with MATLAB’s rand function. Furthermore, we used the convenience rate law of Liebermeister and Klipp [5] to set the enzyme kinetic rate laws for the riboflavin pathway reactions. These rate laws were the basis for the derivation of the scaled elasticity expressions, which depend on scaled metabolite concentrations. The scaled metabolite concentrations were calculated as described above, and inserted in the derived scaled elasticity expressions to obtain the scaled 𝐯 elasticity values in 𝐄𝐌 . As an example, we chose the GTP cyclohydrolase II reaction (reaction 1) to show the derived rate laws and scaled elasticity expressions. The basis for the derivation of the scaled elasticity expressions for reaction 1 is the following reaction equation: GTP ⇋ B + HCOOH + PP𝑖 (S6) 2 Compared with the stoichiometry shown in Fig. 1 (main text), we ignored water in this reaction equation. In general, for the derivation of the scaled elasticity expressions, we excluded water as a reactant or product in the reaction stoichiometries of the pathway [6]. Based on the stoichiometry of Eq. (S6), we deduced the subsequent rate equations for the forward and backward fluxes using the convenience rate law [5]: 𝑣+,1 = 𝑣max,+,1 ∙ 𝑣−,1 = 𝑣max,−,1 ∙ 𝑔𝑡𝑝 1+𝑔𝑡𝑝+ℎ𝑐𝑜𝑜ℎ(1) +𝑏(1) +𝑝𝑝𝑖 (1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) +ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖 𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖 1+𝑔𝑡𝑝+ℎ𝑐𝑜𝑜ℎ(1) +𝑏(1) +𝑝𝑝𝑖 (1) (S7) (1) +𝑏(1) ∙𝑝𝑝𝑖 (1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖 (1) (1) +𝑏(1) ∙𝑝𝑝𝑖 (1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖 (1) (1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) +ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖 (S8) where the lowercase letters of the metabolites represent the scaled metabolite concentrations. As an example, 𝑏(1) represents the scaled concentration of metabolite B in the form of Eq. (S5) ([B]/𝐾M,B,1 ) for reaction 1 and 𝑣max,+,1 and 𝑣max,−,1 are the maximum forward and maximum backward rates of reaction 1, respectively. For these rate equations [Eqs. (S7) and (S8)], the scaled elasticity expressions with respect to metabolite B are as follows: 𝑣 𝐸B+,1 = 𝑣 𝐸B−,1 = −𝑏(1) ∙(1+ℎ𝑐𝑜𝑜ℎ(1) +𝑝𝑝𝑖(1) +𝑝𝑝𝑖(1) ∙ℎ𝑐𝑜𝑜ℎ(1) ) (S9) 1+𝑔𝑡𝑝+ℎ𝑐𝑜𝑜ℎ(1) +𝑏(1) +𝑝𝑝𝑖(1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) +ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖(1) +𝑏(1) ∙𝑝𝑝𝑖(1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖(1) 1+𝑔𝑡𝑝+ℎ𝑐𝑜𝑜ℎ(1) +𝑝𝑝𝑖(1) +ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖(1) (S10) 1+𝑔𝑡𝑝+ℎ𝑐𝑜𝑜ℎ(1) +𝑏(1) +𝑝𝑝𝑖(1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) +ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖(1) +𝑏(1) ∙𝑝𝑝𝑖(1) +𝑏(1) ∙ℎ𝑐𝑜𝑜ℎ(1) ∙𝑝𝑝𝑖(1) 𝒗 Statistical parameters describing the distribution of the scaled flux control coefficient 𝑪𝒆𝟏𝐧𝐞𝐭,𝟕 as a function of the number of generated states To analyze how many generated steady states are necessary to reach nearly invariant statistical parameters, we simulated the system 23 times with an increasing number of generated states. We started with four generated states in the first simulation. In the last simulation, we generated 2.25 × 106 states. For each simulation, we calculated the typical statistical parameters describing the distributions of the calculated scaled control coefficients. To show the behavior of statistical parameters for an increasing number of states, we plotted the 𝑣 mean, median, and 75% and 25% quantiles of the distributions of the scaled flux control coefficient 𝐶𝑒1net,7 against the number of generated states. 3 𝑣 Figure S1 Statistical parameters describing the distribution of the scaled flux control coefficient 𝐶𝑒1net,7 as a function of the number of generated states. The stars represent the 75% quantiles of the distributions. The circles are the mean values of the distributions. The triangles are the median values of the distributions. Squares correspond to the 25% quantiles of the distributions The variability of the means, medians, and 75% and 25% quantiles decreases with increasing number of generated states. All of the four parameters converge to nearly invariant parameter values (mean, 0.45; median, 0.42; 75% quantile, 0.63; 25% quantile, 0.26). These nearly invariant values are reached for approximately 2 × 104 generated states. Consequently, for the metabolic control analysis approach used, it is sufficient to simulate the system with 2 × 104 generated states. A further increase in the number of generated states does not significantly change the results of the probabilistic metabolic control analysis. However, in this study, we decided to show the results for 2.25 × 106 generated states. The comparison between the ranges of the optimized and sampled transformed Gibbs energies of the reactions, and therefore the evaluation of the Gibbs energy sampling methodology, are more meaningful for a larger number of generated states. 4 Sampled logarithmic concentrations of metabolites E and H Figure S2 Distribution histograms for the sampled logarithmic concentrations of metabolite E and H. Both distributions are assembled from 2.25 × 106 values Because the standard transformed Gibbs energy of reaction for lumazine synthase (reaction 6) is 4 ± 12 kJ mol−1, high logarithmic concentrations of metabolite E and low logarithmic concentrations of metabolite H are needed to drive the transformed Gibbs energy of reaction for lumazine synthase (reaction 6) to negative values. 5 Statistical evaluation of the scaled control coefficients for the E. coli enzyme setup [𝑋] Figure S3 Median values of 𝐶𝑒𝑌 (8 × 7) for the E. coli enzyme setup (considering bifunctional enzymes). Each single median is calculated from 2.25 × 106 scaled concentration control coefficients. The reaction numbers 𝑖 of the catalyzed reaction(s) are shown in brackets below the enzyme abbreviation 6 𝑣 Figure S4 Statistical parameters describing the distributions of 𝐶𝑒𝑌net,7 for the E. coli enzyme setup (considering bifunctional enzymes). Each distribution consists of 2.25 × 106 calculated scaled flux control coefficients. The middle lines of the boxes show the medians of the distributions. The upper and lower bounds of the boxes represent the 75% and 25% quantiles, respectively. The upper and lower whiskers are defined here as 95% and 5% quantiles, respectively. Squares correspond to the mean values of the distributions. The reaction numbers 𝑖 of the catalyzed reaction(s) are given in brackets below the enzyme abbreviation Calculation of the scaled flux control coefficients with larger 𝚫𝐫 𝐆′𝟎 ± 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 ranges To examine the influence of the 𝚫𝐫 𝐆′𝟎 ± 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 ranges on the statistical parameters of the scaled flux control coefficients, we performed a simulation with doubled values of 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 . For this simulation, we generated 4 × 104 states. 7 𝑣 Figure S5 Statistical parameters describing the distributions of 𝐶𝑒𝑖net,7 for the one-step one-enzyme setup (i.e., the number of enzyme concentrations is equal to the number of net fluxes). Each distribution consists of 4 × 104 calculated scaled flux control coefficients. The simulation was performed with doubled values of 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 . The middle lines of the boxes show the medians of the distributions. The upper and lower bounds of the boxes represent the 75% and 25% quantiles, respectively. The upper and lower whiskers are defined here as 95% and 5% quantiles, respectively. Squares correspond to the mean values of the distributions The statistical parameters calculated in this simulation are similar to the statistical parameters shown in Fig. 6a 𝑣 (main text). The same flux control trend is obtained. Therefore, the statistical parameters of 𝐶𝑒𝑖net,7 are relatively insensitive to the larger 𝚫𝐫 𝐆′𝟎 ± 𝐄𝐫𝐫(𝚫𝐫 𝐆′𝟎 )𝐌𝐀𝐗 ranges. 8 References – Supporting Information 1. Chakrabarti, A., Miskovic, L., Soh, K. C., & Hatzimanikatis, V. (2013). Towards kinetic modeling of genome-scale metabolic networks without sacrificing stoichiometric, thermodynamic and physiological constraints. Biotechnology Journal, 8, 1043–1057. 2. Benham, T. (2011). Uniform distribution over a convex polytope. MATLAB Central File Exchange. Available from: http://www.mathworks.com/matlabcentral/fileexchange/34208-uniform-distributionover-a-convex-polytope/content/cprnd.m. Accessed 25 September, 2013. 3. Kaufman, D. E., & Smith, R. L. (1998). Direction choice for accelerated convergence in hit-and-run sampling. Operations Research, 46, 84–95. 4. Wang, L., Birol, I., & Hatzimanikatis, V. (2004). Metabolic control analysis under uncertainty: framework development and case studies. Biophysical Journal, 87, 3750–3763. 5. Liebermeister, W., & Klipp, E. (2006). Bringing metabolic networks to life: convenience rate law and thermodynamic constraints. Theoretical Biology and Medical Modelling, 3, 41. 6. Bisswanger, H. (2000). Enzymkinetik. Theorie und Methoden, 3rd ed., Wiley-VCH, Weinheim. 9