12-15 Deposit Stress Brochure

advertisement

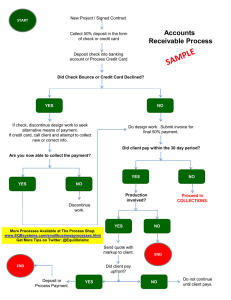

DEPOSIT STRESS ANALYZER Prevent Deposit Flaking Before It Occurs A STRESS MEASUREMENT METHOD APPLICABLE FOR THIN METALLIC COATINGS ECONOMICAL TO USE RAPID DETERMINATIONS ACCURATE RESULTS PRECALIBRATED TEST STRIPS SMALL SAMPLE SURFACE AREA SMALL ELECTROLYTE VOLUME NEW EASY CALCULATION Revised date: 12/01/2015 SPECIALTY TESTING & DEVELOPMENT CO. 137 Reynolds Mill Road • YORK, PENNSYLVANIA 17403 • USA PHONE (717) 428-0186 • FAX (717) 428-0294 www.specialtytest.com T 1. EQUIPMENT DESCRIPTION The Deposit Stress Analyzer System is comprised of an economical, disposable Test Strip, a selection of Plating Cells, and PN 683 Measurement Stand. The Test Strip has a small surface area. It can be plated in a work tank or in a laboratory setting using an appropriate Plating Cell. The Cell offers a standard anode to cathode spacing to ensure uniform current density across the Test Strip legs. After plating, the Test Strip is placed on a Test Stand to measure in increments the distance that the Test Strip leg tips have spread. The distance is included in a formula to calculate the deposit stress in pounds per square inch. Stress is also determined to be compressive or tensile in nature. Small permanently mountable plating cells are also available. See pages 4 and 5. ST To determine the thickness of a nickel deposit that weighed .0349 grams, the calculation would become: T= .0349 x .0509 = .000200 inch 8.90 After the deposit thickness is known and the number of increments spread between the test strip leg tips has been determined, the deposit stress can be calculated thus: S = UKM÷3T PN:1194 M=1.714 PN:2042B M=1.429 PN:270 NI M=1.000 The measuring device supports the plated test strip over the scale so the number of scale increments between the tips of the test piece can be read. The increment reading can then be included in a formula to calculate the internal deposit stress in pounds per square inch. where S = pounds per square inch, U = number of increments spread, T = deposit thickness in inches, K is the strip calibration constant, and M equals the modulus of elasticity of the deposit ÷ by the modulus of elasticity of the substrate material. 2. TEST PROCEDURE Each lot of test strips manufactured will respond with slight differences when used for deposit stress tests. This degree of difference is determined by the supplier for each lot of test strips manufactured. The value for K, a calibration factor, is supplied with each lot of test strips shipped. Activate using a mild non-alkaline soak cleaner, water rinse, immerse in 5% sulfuric acid for 15 seconds, and water rinse. Best results are obtained with a plating set up similar to the photographs on page 4. Electrical contact should be made at the top of the test strip. The current density should approximate the value at which work is plated. The plating test should be continued until the test strip legs deflect from 2-20 units for the most accurate results. The required plating time can be determined experimentally by examining the degree of spread after each minute of plating. Metallic deposits should not exceed an average thickness of 150 microinches unless the deposit is soft such as tin. If the stress is near zero, a reading as low as 1 unit may result. Where T is in inches, K= 3TS UM Where T is in centimeters, K= 3TS 2.54 (UM) For test strip calibration, the value for S is determined by the spiral contractometer method as a certified value. 3. CALCULATIONS If the test strip legs are spread outward on the side that has been plated (plated side out and resist side in) the deposit stress is tensile in nature. If the test strip legs are spread inward on the side that has been plated, the deposit stress is compressive in nature. It is necessary to know the total units or increments spread between the plated test strip leg tips from both sides of the center line on the measuring block scale and the average deposit thickness in order to calculate the deposit stress. If the deposit thickness cannot be determined by actual measurement, it can be calculated as follows: T= W = Inches D (7.74 cm2) (2.54 cm / inch) where T = deposit thickness in inches, W = deposit weight in grams, D = specific gravity of the deposited metal in grams per cubic centimeter and A = surface area in square centimeters. Since the plated surface area on a test strip is 7.74 square centimeters, the formula for nickel thickness can be shortened as follows: T = 0.0509 (W÷D) page 2 4. TABLE OF DENSITY VALUES (GRAMS/CUBIC CENTIMETER) Deposited Metal Density Cadmium 8.65 Chromium 7.19 Copper 8.96 Gold (Soft) 19.45 Gold (Hard) 17.60 Nickel 8.90 Palladium 12.00 Platinum 21.45 Rhodium 12.44 Ruthenium 12.20 Silver 10.49 Tin 7.30 Zinc 7.13 ST 5. TEST STRIPS The test strips are made from materials that have spring like properties. Thus, even if the test strip legs are accidentally moved prior to reading the increments spread, they will return to the correct position so a correct reading can be obtained. They are applicable for all acidic and alkaline plating chemistries, but certain high cyanide solutions may require an additional resist coating such as a thin coating of Micro-Shield stop off lacquer diluted 50 percent with acetone and applied with an artist brush. *PN: 1194 Test Strips are made from Copper-Iron Alloy material 0.002 inch thick for deposit stress determinations between 2,000 – 145,000 psi tensile or compressive stress. Use a Wood’s Ni strike if required for 5 seconds at 50asf, 0.42 amps, to activate for chemical plating. *PN: 2042B Test Strips are made from Nickel-Iron Alloy material 0.0015 inch thick for tensile deposit stress determinations between 500 – 80,000 psi. This material self- activates in most electroless plating baths. *Pricing (Sold in lots of 25 pcs.): 25-75 pcs. $6.25 each piece 100-475 pcs. $6.10 each piece 500+ pcs. $ 5.95 each piece Test For Nickel (100µ inch deposits) ASF AMPERES TIME 10 .083 12 minutes 30 .25 4 min. **PN: 270NI This is the most sensitive test strip (pure Nickel 0.0011 inch thick) having particular application for low internal deposit stress values. It is ideal for nickel, electroless nickel & nickel alloys, chromium, tin, silver, gold, palladium, platinum, and rhodium. These test strips measure a range of 100-50,000 PSI tensile or compressive stress. **Pricing (Sold in lots of 25 pcs.): $ 7.00 each piece Tensile (Matte) PN: 1194 PN: 2042 B PN: 270 NI Compressive (Bright) PN: 1194 N/A PN: 270 NI PN: 3194 Test Strips are made from Copper 194 material. These strips have no masking material and are sold in lots of 25 pcs. for $3.95 each. These strips have application for thin organic coatings including resists, and thin ceramic coating.Simply apply the coating on opposite sides of the test strip legs uniformly and cure or bake. They also have an application for high cyanide chemistries with the use of Micro-Shield stop-off lacquer that can be brush applied to define the areas for deposition. Remove this lacquer with acetone prior to measuring the spread. Internal stress exists as an inherent force within electroplated and chemically applied metallic coatings. This induced stress can be tensile or compressive in nature, causing the deposit to contract or expand in relation to the base material. High levels of stress in deposits produce micro-cracking and macro-cracking in the applied layers, and in severe cases produce a lack of deposit adhesion in the form of blistering, peeling, and flaking, wave-like ripples in electroforms, and accelerated corrosion and wear failure. TEST STRIP AND ANODE CONSIDERATIONS Metallic Deposit Test Strip Anodes* Cadmium 1194 Cadmium Chromium 270NI, 2042B Lead Cobalt 1194 Cobalt Copper 1194 Copper Gold 270NI, 2042B Platinum Coated Titanium Nickel 1194 Nickel Palladium 1194, 2042B Platinum Coated Titanium Platinum 270NI, 2042B Platinum Rhodium 270NI, 2042B Platinum Coated Titanium Silver 1194 Silver Tin 1194 Tin Zinc 1194 Zinc *Two are required, similar in composition, shape and size. Anodes 2x2x1/8” can be purchased from Kocour Company page 3 T ST DEPOSIT STRESS ANALYZER TEST PROCEDURES FOR TEST STRIPS (COPPER-IRON ALLOY, IRON-NICKEL ALLOY, AND COLD ROLLED NICKEL MATERIAL) Any deposited metallic coating can be tested for stress using the DSA Method. Note that this test strip material is applicable for both tensile and compressive stressed deposits. A Wood’s Nickel Strike may be required for chemically applied coatings. TEST EQUIPMENT PN: 800L Plating Test Cell (price includes PN: 404 submersible mini pump). PN: 3046 Electric Immersion Heater (Note: Heater maintains + 1° F). GraLab Timer 60 Minutes or equivalent with automatic shut off. PN: 683 Deposit Stress Analyzer Stand with Measuring Scale. Rectifier to supply the direct current amperage for plating. A constant current constant voltage power supply is recommended preferably a zero to two amp output with low ripple. The desired Test Strips. Two Nickel Anodes 2 x 2 x 1/8 inch (Can be purchased from Kocour Company, 4800 South St. Lewis Avenue, Chicago, IL 60632, 1-773- 847-1111). TEST SET-UP 1. Place the anodes in the plating cell anode pockets at the cell ends. 2. Place the heater in the plating cell (see brochure photo). 3. Set the pump slide bar to its lowest setting (one notch from OFF). Dampen the suction cups on the submersible pump with water and fasten the pump to the side of the cell so it rests on the cell bottom with its side located ½ inch from the cell end wall and the outlet directed toward the cell wall opening. Agitation in the plating side of the cell must be limited to prevent the test strip legs from swaying to favor one anode over the other. 4. Fill the cell with the plating bath to be evaluated to within one half inch of the top of the cell. 5. Connect the positive lead from the power supply to the aluminum anode contact provided on the cell. Connect the red leads on the cell to the respective anodes. 6. Use the negative lead to fasten a given test strip to the stainless steel support mounted on the cell. 7. Plug the rectifier into the automatic timer. 8. Plug the timer, heater and pump into a 120 Volt source. 9. Heat the plating solution to the operating temperature. TEST PROCEDURE 1. Soak clean a sample test strip in a soak cleaner solution at 110 - 120°F for 30 seconds to remove any contamination, then water rinse. 2. Immerse in a 5% by volume hydrochloric acid solution for 30 seconds at room temperature, then water rinse. 3. Place the sample test strip in the plating cell by clipping the test strip to the stainless steel cross support so as to have the test strip centered between the cell walls with the test strip leg tips approximately 1/16th inch from the plating cell bottom. In this position, the top of the test strip should be approximately 3/16th inch above the support cross bar. 4. Turn the agitation pump ON and set the timer for the appropriate plating time. 5. Use a sample test strip to adjust the plating current to the specified amperage. Maintain this rectifier setting for all other test strips to be plated. 6. Replace the sample test strip with the one to be evaluated. This test strip should be conditioned as above and exposed to the plating solution about 30 seconds prior to beginning nickel deposition to assist in surface activation. 7. Set the timer for the desired plating time and turn on the power supply. 8. Use the timer to end the plating cycle. 9. At the end of the plating cycle, remove the test strip from the cell. 10. Rinse the test strip in water, then rinse it in isopropyl alcohol. Lay the test strip on a paper towel and blot it dry with another paper towel. A paper towel can be folded over and the test strip can be pulled through it. 11. Place the test strip on the measuring stand as near to two minutes as possible, and read and record the total increments spread as the value for U. DESPOSIT STRESS EQUATION 1. For critical certifiable work, average the results of these plated test strips. 2. Solve the following equation for the internal deposit stress and record this value as pounds/square inch. S = UKM ÷ 3T page 4 ST TEST STRIP MATERIAL: COPPER-IRON ALLOY 0.0020 INCH THICK, PN: 1194 PLATING CONDITIONS FOR NICKEL Temperature 130 Current Density 30 Plating Current 0.25 Plating Time: 4 Deposit Thickness 100 PLATING: ºF Amps/square foot Amps Minutes 12 seconds (95% cathode efficiency) Microinches DEPOSIT STRESS EQUATION Solve the equation S = UKM ÷ 3T as follows: U = Total increments spread of the test strip leg tips on both sides of the zero line. T = Deposit thickness in inches. K = The calibration constant value provided by the manufacture. M = 1.714. The correction factor for the difference in the modulus of elasticity between the deposit and that of the substrate = EDeposit ÷ ESubstrate = 206900 ÷ 120,690 = 1.714. S = The internal deposit stress in pounds per square inch. S= PSI 2 2 Note: 1 PSI x 703.1 kgm ÷ PSI = kgm . TEST STRIP MATERIAL: IRON-NICKEL ALLOY 0.00150 INCH THICK, PN: 2042B. Note that this test strip material is applicable for tensile stressed deposits only. It cannot be used for compressive stressed deposits. It is self- activating for chemical plating. Any deposited metallic coating can be tested for stress using the DSA Method PLATING CONDITIONS FOR NICKEL PLATING: Temperature 130 ºF Current Density 30 Amps/square foot Plating Current 0.25 Amps Plating Time: 3 Minutes 9 seconds (95% cathode efficiency) Deposit Thickness 75 Microinches DEPOSIT STRESS EQUATION Solve the equation S = UKM ÷ 3T as follows: U = Total increments spread of the test strip leg tips on both sides of the zero line. T = Deposit thickness in inches. K = The calibration constant value provided by the manufacture. M = 1.429. The correction factor for the difference in the modulus of elasticity between the deposit and that of the substrate = EDeposit ÷ ESubstrate = 206900 ÷ 144830 = 1.429. S = The internal deposit stress in pounds per square inch. S= PSI TEST STRIP MATERIAL: PURE COLD ROLLED NICKEL 0.0011 INCH THICK, PN: 270NI. Note that this test strip material is applicable for the determination of tensile and compressive stressed deposited metallic coatings. It is the most sensitive test strip and is autocatalytic for most chemically applied coatings. PLATING CONDITIONS FOR NICKEL PLATING: Temperature 130 ºF Current Density 30 Amps/square foot Plating Current 0.25 Amps Plating Time: 2 Minutes 6 seconds (95% cathode efficiency) Deposit Thickness Target 50 Microinches * If the above test conditions cause the test strip leg tips to spread beyond 24 units due to high internal deposit stress, reduce the deposition time and the deposit thickness for the test to improve accuracy. DEPOSIT STRESS EQUATION Solve the equation S = UKM ÷ 3T as follows: U = Total increments spread of the test strip leg tips on both sides of the zero line. T = Deposit thickness in inches. K = The calibration constant value provided by the manufacture. M = 1.000, the correction factor for the difference in the modulus of elasticity between the deposit and that of the substrate = EDeposit ÷ ESubstrate = 206900 ÷ 206900 = 1.000. S = The internal deposit stress in pounds per square inch. S= PSI page 5 TABLE 1 Values for M to Determine Compressive and Tensile Deposit Stress for Various Deposited Coatings Stock Material E* Stock Thickness, in Metal Cadmium Chromium Cobalt Copper Gold Nickel Platinum Rhodium Silver Tin Zinc M** 31,720 248,280 206,897 117,240 74,480 206,900 146,900 289,650 75,860 59,310 82,760 1194 120,690 0.0020 0.263 2.06 1.72 0.971 0.617 1.71 1.22 2.400 0.629 0.491 0.686 2042B 144,830 0.0015 270NI 206,900 0.0011 0.001 Values for M*** 0.219 0.153 1.71 1.20 1.43 1.00 0.810 0.567 0.514 0.360 1.43 1.00 1.02 0.710 2.000 1.400 0.524 0.367 0.410 0.287 0.571 0.400 E* modulus of of elasticity elasticity of the substrate substrate material M** modulus modulus of of elasticity elasticity of of the the deposit deposit modulus of of elasticity elasticity of of the the deposit/modulus deposit/modulus of of elasticity elasticity of of the the substrate M*** modulus stubstrateinin the modified modified Deposit Deposit Stress StressAnalyzer Analyzerand Formula. electroless alloy deposits, the StoneyFor Formulas. For nickel electroless check the Table at www.specialtytest.com. For other alloy deposits, obtain nickel alloy deposits check the Table at www.specialtytest.com. For other the Modulus of Elasticity the supplier. alloy deposits, obtain from the Modulus of Elasticity from the supplier. NOTE: P/N Z042 B is only applicable for tensile stress determinations. TABLE 2 Electrolyte Cadmium Chromium Copper (cyanide) Copper (acidic) Gold (soft) Gold (hardened) Nickel Palladium Platinum Rhodium Silver Tin(alkaline) Tin (acidic) Zinc (acidic) Zinc (cyanide) Zinc (alkaline) Approximate Deposition Rates for Metals % Efficiency Amps ASF* µ"/Minute Deposit, µ" ** 95 20 80 98 93 40 95 95 85 60 99 60 70 98 98 85 98 85 80 0.33 2.90 0.16 0.33 0.08 0.33 0.33 0.25 0.04 0.08 0.16 0.25 0.42 0.25 0.25 0.25 0.25 40 350 20 40 10 40 40 30 5 10 20 20 50 30 30 30 30 26.1 10 30.8 36.3 26 44.5 31.7 37.5 2.55 4.37 59.4 15 107.8 22.4 30.8 36.2 30.2 24 200 20 100 100 100 75 75 100 200 20 200 200 200 200 200 200 Note: Zinc Cyanide dissolves the resist. Use stop-off lacquer over the resist, then remove with acetone and measure. *Convert amps per square foot to amps per square decimeter by dividing the numbers shown above by 10 ** Average deposit thickness recommended on test strips. page 6