IMS 1.0

Intelligent Mining Software “Solutions”

IMS - Convert a Laminar Model to a

Block Model

Produced by W.S. Mart and G. Markey

For MineMap Pty Ltd

Intelligent Mining Software “Solutions” IMS - Convert a Laminar

Model to a Block Model

Copyright © 2013 by William Seldon Mart and Geoff Markey. All rights reserved.

Page 1

Intelligent Mining Software “Solutions” IMS - Convert a Laminar

Model to a Block Model

Table of Contents

INTRODUCTION................................................................................................................................ 3

EXPORTING A LAMINAR MODEL TO A BLOCK MODEL ....................................................... 4

Page 2

Intelligent Mining Software “Solutions” IMS - Convert a Laminar

Model to a Block Model

INTRODUCTION

While IMS operates both block and laminar models the Lerches-Grossman Pit Optimization plugin

can only operate on block models. To overcome this limitation IMS can convert any laminar model

into an equivalent block model.

Page 3

Intelligent Mining Software “Solutions” IMS - Convert a Laminar

Model to a Block Model

EXPORTING A LAMINAR MODEL TO A BLOCK MODEL

1. Make sure a model definition is available to receive the converted model. The block model

must have the same number of cells, cell sizes and rotation as the laminar model - only the

stratigraphic units and assays will differ. To create such a definition:

a. Right click on the required laminar model in the File Explorer Pane to display the

pop-up menu for the pane.

b. Select the <Copy Definition…> menu item to display the Model Settings wizard.

c. In the Main page change only the File and Title of the definition.

d. Select the Stratigraphy page.

e. Delete all the seam names.

f.

Add the stratigraphies for the block model. The <Add multiples> button to do this

efficiently.

g. Select the Assays page.

h. If a quality named ‘Coal Percent’ (or similar) is not present then add the quality

making sure it has a usage of "Ore proportion". This assay, with the assigned usage,

must be present in the block model.

i.

If a quality named ‘Coal RD’ (or similar) is not present then add the quality making

sure it has a usage of "RD of Lerch ore percent ". This assay, with the assigned usage,

must be present in the block model.

j.

Save the new block model definition.

2. Drag the model definition used in step 1 from the File Explorer Pane to either the Loaded

Files Pane or 3D view Pane to load the file.

3. Create an empty block model (see the Block Model Operations manual for more information.)

4. Unload the block model.

5. Drag the required laminar model from the File Explorer Pane to either the Loaded Files

Pane or 3D view Pane to load the file.

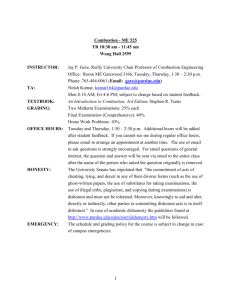

6. Select the <Model><Laminar Model Operations><Export to Block Model…> menu item

to display the Convert Laminar Model dialog box (Figure 1)

Page 4

Intelligent Mining Software “Solutions” IMS - Convert a Laminar

Model to a Block Model

Figure 1: Convert Laminar Model dialog box

7. Select the block model created in step 3 as the Output block model.

8. Enter a value for the RD of Ore. This value is used if relative density is not modelled or if a

cell has a relative density less than 0.1.

9. Select the Leave unmodelled areas in the output model check box if required. This is useful

if areas outside the region file should be written to the block model. These areas can be

flagged as air blocks in the block model, or left as cells containing zero percent coal.

10. Select the Transfer assays check box if the assays should be copied to the block model.

11. Select the Dilute assays using waste with RD check box if required and enter a value.

12. Enter he background waste values for the Assays.

13. Press the <OK> button to update the "Coal Percent" and "Coal RD" assays in the block

model. The resulting block model is now ready for the Lerches-Grossman Pit Optimization

process.

Page 5