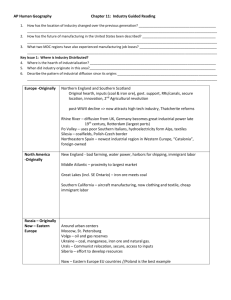

chapter n0-5 indian textile

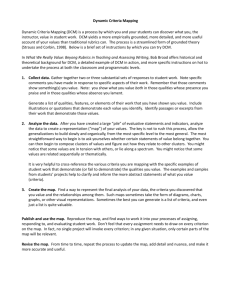

advertisement