5862

advertisement

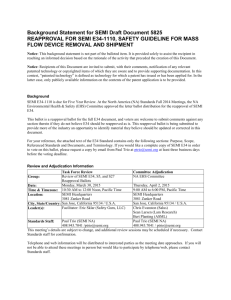

Background Statement for SEMI Draft Document 5862 REAPPROVAL OF SEMI PV3-0310 GUIDE FOR HIGH PURITY WATER USED IN PHOTOVOLTAIC CELL PROCESSING Notice: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this Document. Notice: Recipients of this Document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided. Background Per SEMI Regulations 8.9.1, the Originating TC Chapter shall review its Standards and decide whether to ballot the Standards for reapproval, revision, replacement, or withdrawal by the end of the fifth year after their latest publication or reapproval dates. The NA PV Materials TC Chapter reviewed and recommended to issue for reapproval ballot. Per SEMI Procedure Manual (NOTE 19), a reapproval Letter Ballot should include the Purpose, Scope, Limitations, and Terminology sections, along with the full text of any paragraph in which editorial updates are being made. Voter requests for access to the full Standard or Safety Guideline must be made at least three business days before the voting deadline. Late requests may not be honored. Review and Adjudication Information Task Force Review International PV Analytical Test Methods, Metrology, and Inspection TF July 15, 2015 Date: Time & Timezone: 10:00 AM – Noon PDT San Francisco Marriott Marquis Location: San Francisco, CA/USA City, Group: State/Country: Leader(s)/Authors: Hugh Gotts (Air Liquide) Standards Staff: Kevin Nguyen (knguyen@semi.org ) Committee Adjudication NA PV Materials TC Chapter July 15, 2015 1:00 PM – 4:00 PM PDT San Francisco Marriott Marquis San Francisco, CA/USA Hugh Gotts (Air Liquide) Lori Nye (Brewer Science) John Valley (Sun Edison) Kevin Nguyen (knguyen@semi.org ) This meeting’s details are subject to change, and additional review sessions may be scheduled if necessary. Contact the task force leaders or Standards staff for confirmation. Telephone and web information will be distributed to interested parties as the meeting date approaches. If you will not be able to attend these meetings in person but would like to participate by telephone/web, please contact Standards staff. Check www.semi.org/standards on calendar of event for the latest meeting schedule. Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 DRAFT SEMI Draft Document 5862 REAPPROVAL OF SEMI PV3-0310 GUIDE FOR HIGH PURITY WATER USED IN PHOTOVOLTAIC CELL PROCESSING 1 Purpose 1.1 This guide is provided for multiple purposes. It may be used as a basis for establishing performance criteria for purchases of new High Purity Water (HPW) equipment. It may also be used internally by facility engineers to set process control parameters for the operation of their HPW systems. This guide may be used by process engineers to establish reasonable expectations about the quality of the HPW being supplied to them by facilities. NOTE 1: These suggested guidelines are published as technical information and are intended for informational purposes only. 2 Scope 2.1 Water is used extensively in the production of photovoltaic cells and associated manufacturing for all wet processing steps such as the rinsing of substrate wafers and panels. HPW is typically produced for this purpose using Reverse Osmosis/Deionized resin bed technologies. The quality of the water impacts device yield. Requirements for higher purity water may increase with changes in the photovoltaic cell over time. 2.2 The guidelines are targeted for HPW produced for photovoltaic manufacturing. 2.3 The guidelines consider both general photovoltaic manufacturing facilities as well as critical manufacturing tools. 2.4 Location for water quality specification is defined at Point-of-Use (POU), which is a Point of Connection (POC) of the manufacturing tool on the HPW distribution lateral. NOTICE: This standard does not purport to address safety issues, if any, associated with its use. It is the responsibility of the users of this standard to establish appropriate safety and health practices and determine the applicability of regulatory or other limitations prior to use. 3 Limitations 3.1 This guide is not intended to set an absolute performance requirement for a HPW system. Performance requirements should be determined based on the sensitivity of the manufacturing process to the purity of the water, the sensitivity of the instrumentation, and the costs associated with installation, maintenance, and monitoring the water system parameters. 3.2 This set of guidelines has been established from a variety of sources and inputs including; (1) an industry survey that SEMI Photovoltaic Standards Committee provided to members of its standards activities; (2) typical HPW levels from a large selection of photovoltaic HPW systems, as measured by independent laboratories that test high purity water for the photovoltaic industry; (3) specifications from water system equipment manufacturers; and (4) input from producers and users of HPW during SEMI Photovoltaic Standards Committee meetings and through the balloting process. However, it is up to each individual owner of a HPW system to set specifications for the purity of its water based on the owner’s needs and available resources. 3.3 ASTM D5127 is considered in setting specifications for the purity of reagent grade water needed in a laboratory for analytical testing of photovoltaic materials and process chemicals. 3.4 The guidelines are based on current state-of-the-art PV manufacturing and do not take into account enabling future technologies. 3.5 The quality of the data measured will depend on which testing method and calibration techniques are used. Consequently, trends observed in the values may be as meaningful as absolute values. 4 Referenced Standards and Documents 4.1 SEMI Standard This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 1 Doc. 5862 SEMI LETTER BALLOT Document Number: 5862 Date: 2/9/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 DRAFT SEMI C1 — Guide for the Analysis of Liquid Chemicals 4.2 ASTM Standards1 ASTM D859 — Standard Test Method for Silica in Water ASTM D2791 — Standard Test Method for On-line Determination of Sodium in Water ASTM D4327 — Standard Test Method for Anions in Water by Chemically Suppressed Ion Chromatography ASTM D5127 — Standard Guide for Ultra Pure Water Used in the Electronics and Semiconductor Industries ASTM D5173 — Standard Test Method for On-Line Monitoring of Carbon Compounds in Water by Chemical Oxidation, by UV Light Oxidation, by Both, or by High Temperature Combustion Followed by Gas Phase NDIR or by Electrolytic Conductivity ASTM D5391 — Standard Test Method for Electrical Conductivity and Resistivity of a Flowing High Purity Water Sample ASTM D6317 — Standard Test Method for Low Level Determination of Total Carbon, Inorganic Carbon and Organic Carbon in Water by Ultraviolet, Persulfate Oxidation, and Membrane Conductivity Detection ASTM D7126 — Standard Test Method for On-Line Colorimetric Measurement of Silica ASTM F1094 — Test Method for Microbiological Monitoring of Water Used for Processing Electron and Microelectronic Devices by Direct Pressure Tap Sampling Valve and by the Presterilized Plastic Bag Method NOTICE: Unless otherwise indicated, all documents cited shall be the latest published versions. 5 Terminology 5.1 Abbreviations and Acronyms 5.1.1 HPW — High Purity Water System 5.1.2 RO — Reverse Osmosis 5.1.3 TOC — Total Organic Carbon 5.1.4 UPW — Ultrapure Water System 5.2 Definitions 5.2.1 DI (deionized) water — generally refers to water that has passed through a full-train ion exchange system or RO water that has been polished by ion exchange. 5.2.2 High Purity Water system (HPW) — lower grade than UPW, due to lower requirements for dissolved gases, ions, TOC, bacteria and particles. There are two quality choices to be chosen by end user depending on needs: 5.2.2.1 high purity quality — quality of HPW required for higher sensitivity PV processes. 5.2.2.2 standard purity quality — quality of HPW required for lower sensitivity PV processes. 5.2.3 raw water — any untreated natural water like river water, lake water, ground water, or seawater. May also refer to the treated feed water that enters a plant from a municipal drinking water source or other source. 5.2.4 Reverse Osmosis (RO) — a filtration technology that utilizes a semi-permeable membrane to remove essentially all suspended solids and the vast majority of all dissolved solids. Generally refers to water (permeate) that has passed through a reverse osmosis (RO) membrane. 5.2.5 Total Organic Carbon (TOC) — also Total Oxidizable Carbon. Refers to organic compounds. 5.2.6 treated water — water that has passed through water treatment equipment or received chemical injections or both in order to modify the solids content of the water. 1 American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, Pennsylvania 19428-2959, USA. Telephone: 610.832.9585; Fax: 610.832.9555; http://www.astm.org This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 2 Doc. 5862 SEMI LETTER BALLOT Document Number: 5862 Date: 2/9/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 DRAFT 5.2.7 Ultrapure Water system (UPW) — consisting of multiple components including a Reverse Osmosis (RO) and a Deionization (DI) process. UPW is a higher purity of water that exceeds all the requirements of HPW and is produced by a semiconductor water treatment system, which is sent to the end users for use in manufacturing. NOTICE: SEMI makes no warranties or representations as to the suitability of the standard(s) set forth herein for any particular application. The determination of the suitability of the standard(s) is solely the responsibility of the user. Users are cautioned to refer to manufacturer’s instructions, product labels, product data sheets, and other relevant literature respecting any materials or equipment mentioned herein. These standards are subject to change without notice. By publication of this standard, Semiconductor Equipment and Materials International (SEMI) takes no position respecting the validity of any patent rights or copyrights asserted in connection with any item mentioned in this standard. Users of this standard are expressly advised that determination of any such patent rights or copyrights, and the risk of infringement of such rights are entirely their own responsibility. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 3 Doc. 5862 SEMI LETTER BALLOT Document Number: 5862 Date: 2/9/2016