Melissa Tweedie Thesis Rev 3-28-14

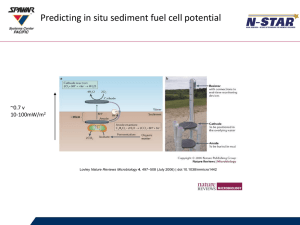

advertisement