Problem Solving Form - Allison Transmission

advertisement

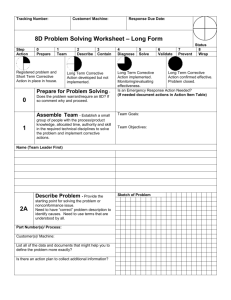

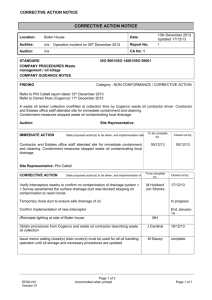

INSTRUCTIONS FOR: Problem Solving Form (AT-10181-1) Note: Use form AT-10181-1 for Non-SQN data or if ITAR data must be included PURPOSE: The purpose of the Problem Solving Summary Form AT-10180 is to provide instructions on how to properly fill out an 8-Step. SCOPE: The Problem Solving Summary Form AT-10180 applies to quality notifications requiring an 8-Step. DEFINITIONS: SQE – Supplier Quality Engineer SQN – SAP Quality Notification OEM – Original Equipment Manufacturer Owner – Internal Person, Supplier Representative, or assignee Responsible to Answer Quality Notification ITAR – International Traffic in Arms Regulations PM – Preventative Maintenance BOB – Best of the Best WOW – Worst of the Worst PFMEA – Failure Mode and Effects Analysis RPN – Risk Priority Number N/A – Not Applicable N/C – No Change GVC – Graphical Verification Check-Sheet EPSV – Error Proofing System Verification REFERENCES: AT-1927-84 Drill Deep Worksheet TABLE OF CONTENTS: Form Title Block……………………………….Page 2 Step 1…………………………………………….Page 3 Step 2…………………………………………….Page 3 Step 3…………………………………………….Page 4 Step 4…………………………………………….Page 4 Step 5…………………………………………….Page 5 Step 6…………………………………………….Page 6 Step 7…………………………………………….Page 6 Step 8…………………………………………….Page 7 Form: AT-10180 Instructions Rev: 05/08/2013 Box A1 must be marked/checked if and only if ITAR data is included on the form. Do not check box A1 if no ITAR data is included. Form Title Block Person Responsible: Administrator, Plant SQE, or assignee This section refers to the title block within the printed 8-Step. These are defined when the SQN is opened. Title: Short description of problem Opened by: SQN Administrator, Plant SQE, or assignee Owner: Internal Person, Supplier Representative, or assignee Responsible to Answer Quality Notification Tracking #: SQN Number Date Opened: Date SQN started in management system Date Closed: Date SQN closed in management system Originating Plant: Plant initiating SQN Where Found: Internal/External location where problem found (May not be same as Originating Plant) Material: Part Number Material Description: Part Description provided by management system Vendor: Supplier Name (for External SQNs) Supplier Support SQE: Name of SQE (for External SQNs) Serial Number: Serial Number (if applicable) Comp. Lot Code: Lot or batch number containing defective part(s) (if applicable) Customer: Company name where problem was found (if applicable) Customer Trk#: Customer Number (if applicable) Form: AT-10180 Instructions Rev: 05/08/2013 1. Problem Description (check box A1 if ITAR data included) Person Responsible: Owner, Plant SQE, or assignee This section includes a complete specific description of the issue. When was the problem found? What was the defect? - Reference part number and print specification - How much out of specification was the part - Attach photos of non-conformance - Attach photos of container labeling (for external SQNs) Where was the problem found? (Broad location to specific) Who found the problem? (not name specific, job specific) How was the problem found? How many units/pieces were initially found? When were the non-conforming parts produced (Include date stamps, operator stamps, lot numbers, etc.)? Is this a repeat non-conformance? If yes, reference prior SQN(s)? NOTE: Please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 2. Measurement Method At the Time Defective Parts/Assemblies Produced ((check box A1 if ITAR data included) Person Responsible: Owner This section covers the gauging/measurement method at the time the defect was produced. How was the measurement method controlled at the time the defect part(s) were produced? If feature not controlled, please state there was no control in place. What was the control plan method used at the time the defect part(s) were produced, include frequency of check and type of gage. Was the gage calibrated? Are there visual inspection standards posted, and are they being used? What process data related to the defect is recorded? NOTE: If a different method was used to sort parts, then that should be included in Step 3 under method of check. If changes are being made to this process as a result of the investigation, then those should be included in Step 6 Corrective Actions. NOTE: Please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 3. Containment Summary (check box A1 if ITAR data included) Person Responsible: Owner, Plant SQE, or assignee This section covers containment of potential non-conforming product. LOCATION: Where did containment activities occur? METHOD OF CHECK: What is the method of check used to contain potential non-conforming product, by location? WHEN: When was containment activities initiated, by location? WHO: Who was responsible for containment activities, by location? SUSPECT QTY: How much was the suspect quantity, or amount of potential non-conforming product, by location? SORTED QTY: If a sort was done, what was the sorted quantity, by location? DEFECT QTY: How many defects were found, by location? NOTE: Containment activity is always expected. Containment should remain in place until corrective action is implemented. If no containment was done, then specific written justification should be included. NOTE: Permanent changes to the gauging process as a result of the investigation should be included in Step 6 Corrective Actions. NOTE: Please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 4. Root Cause Analysis (check box A1 if ITAR data included) Person Responsible: Owner This section documents the root cause problem solving process of the non-conformance found. The root cause of the problem includes not only why there might have been a failure to detect or contain, but also why the process produced the defective part/unit/assembly. All possibilities considered, even if discarded, should be included. All evidence supporting the conclusion should be included. Include detailed step by step investigation of root cause. - If applicable use form AT-1927-84 Drill Deep Worksheet Were Statistical or other Tools used, and with what results? As in: - Gage/Machine/Process Capability Studies - Run/Control Charts - Cause/Effect Diagram - Flow Diagrams, 5- Why Analysis - Pareto Analysis, Histogram Analysis What items did you check, even though it did not create failure? After step by step investigation of root cause is written, make one line definition statement of root cause. Was this root cause a common cause or a special cause? How was that determined? If root cause not determined, provide a root cause analysis detailed plan. (especially ideal for fast response) NOTE: Please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 Step 5. Process Verification – First 4 Steps (check box A1 if ITAR data included) Person Responsible: Owner This section covers questions regarding your current process to help establish root cause corrective action. If answer to questions below is “No”, comments are needed to why not. NOTE: Please ensure this step is completely filled out. 1 Correct Process? Standardized work followed? Standardized work posted? Job done on all shifts the same way? Operator understands standards? Regular operator? Operator properly trained? Operator understands quality outcomes? Operator knows how to communicate quality concerns? 2 Correct Tools? Correct tools / fixtures / error proofing? Has PM been done? Are tools functioning correctly? 3 Correct Parts? Correct Parts? Parts routing current? Parts stocked in correct location? Error proofing needed? 4 Parts Changed? Parts changed? Best of the Best (BOB) vs. Worst of the Worst (WOW) parts different? Parts in spec? Form: AT-10180 Instructions Rev: 05/08/2013 Yes / No / NA Comments 6. Implementation of Corrective Action (check box A1 if ITAR data included) Person Responsible: Owner This section covers the specific, detailed description of all actions implemented to prevent reoccurrence of the problem. WHAT: What is the corrective action(s) implemented? (limited to 40 characters) WHERE: Where, as in location/building/line/cell, is the corrective action(s) implemented? WHEN: When was the corrective action(s) implemented? If corrective action not implemented yet, enter target date. WHO: Who (registered user) implemented the corrective action(s)? NOTE: Changes to detection, specifications, processing elements, error proofing etc. should all be included in this section. The 8-step owner is responsible to coordinate and communicate with those persons responsible for completing identified activities. All items assigned to someone other than the owner of the investigation that are not complete at the time of the 8-step presentation, must be discussed with the responsible party prior to presentation for follow-up. If the item has not been implemented, then implementation dates should be realistic and reflect the agreement of the person assigned. Standard document updates will be reviewed in Step 8 and action items generated from that step. Those changes do not need to be duplicated in Step 6. NOTE: Please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 7. Effectiveness Of Corrective Action (check box A1 if ITAR data included) Person Responsible: Owner This section covers checking results of the corrective actions to ensure effectiveness. WHAT: What specific method was (will be) used to verify the corrective action prevents the root cause from re-occurring? (Gage R&R, Capability Study, Known bad part run, etc.) Lot by lot inspection METHOD: What was (will be) the method type used? WHEN: When was (will be) the verification(s) completed? (leave blank if evaluation not completed) WHO: Who (registered user) completed the verification(s)? RESULTS: What were the results of the verification(s)? (include specific results of the method chosen) - Attach, if possible, data from the above results NOTE: The specific metrics, on-going monitoring systems, and/or permanent reviews that were considered should be separately named and include the method of review, who completed, when and with what results. If the review is not complete because all actions have not been implemented, then the planned review should be detailed. NOTE: Please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 Step 8. Problem Prevention &Institutionalization of Problem Solving (check box A1 if ITAR data included) Person Responsible: Owner This section covers the updates to documentation required and the dates they were completed If an item needs to be completed, put in a target date. Otherwise, check N/A. Always pull the PFMEA, record the date this was done in the PFMEA Review “Date Completed” section. From the PFMEA, record the current RPN and enter the date this was recorded in the RPN Old “Date Completed” section. If Prevention and Institutionalization changed the RPN, record the new RPN and enter the date this was recorded in the RPN New “Date Completed” section. If Prevention and Institutionalization did not change the RPN, record “N/C”, for no change, and enter the date this was recorded in the RPN New “Date Completed” section. If the Control Plan was updated, enter the date this was updated in the Control Plan “Date Completed” section. If the Operating Instructions were updated, enter the date this was updated in the Operating Instructions “Date Completed” section. If a Layered Audit was updated, enter the date this item was updated in the Layered Audit “Date Completed” section. If Error Proofing was implemented / updated, enter the date it was implemented/updated in the Error Proofing “Date Completed” section. If the workforce, as in shift/plant-wide, was notified of the non-conformance, enter the date of the notification in the Workforce Notification “Date Completed” section. If Visual Aids were implemented / updated, enter the date it was implemented/updated in the Visual Aids “Date Completed” section. If a Graphical Verification sheet, or graphical representation plan, was implemented / updated, enter the date this was implemented/updated in the Graphical Verification Check (GVC) Sheet “Date Completed” section. If a Quality Alert was provided to the specific root cause work location, enter the date this was completed in the Quality Alert “Date Completed” section. NOTE: It is strongly recommended a Quality Alert be provided. If a Training Assessment was updated, enter the date this was updated in the Training Assessment “Date Completed” section. Were there any other items updated? If so, what were those items, and when were they completed? NOTE: As with Step 6, the problem solving owner is responsible to coordinate and communicate to those persons responsible for completing a review or update. If all reviews are not complete at the time of presentation, the responsible party must be in agreement with the target date expected. NOTE: If applicable, please ensure this step is completely filled out. Form: AT-10180 Instructions Rev: 05/08/2013 8. Problem Prevention & Institutionalization of Problem Solving Target Date ITEMS TO UPDATE PFMEA Reviewed RPN Old = RPN New = Control Plan / Step Sheets Operating Instructions (JES) Layered Audit Errorproofing Workforce Notified/Discussion Log Visual Aids Graphical Verification Check (GVC) Sheet Quality Alert Training Assessment Other (Tool Layout, Containment Sheets) Read Across / Institutionalization Form: AT-10180 Instructions Rev: 05/08/2013 (check box A1 if ITAR data included) Date Completed Who CHANGE HISTORY Revised By: Lee Hickerson (approved by Plant Quality Managers) Barbara McCall (approved by Plant Q Managers and Sara Glassburn) Form: AT-10180 Instructions Rev: 05/08/2013 Date: 06/27/2011 05/08/2013 Comments: Added Purpose, Scope, Definitions, References, and Table of Contents. Added Person Responsible for Each Section. Significantly updated the ‘bullets’ describing what is to be included in each section. Combined ITAR and non –SQN Problem Solving forms.