Environmental Form - University of Warwick

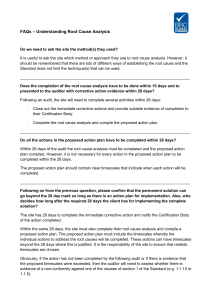

advertisement

CORRECTIVE ACTION NOTICE CORRECTIVE ACTION NOTICE Location: Boiler House Auditee: n/a Auditor: n/a Operation incident on 05th December 2013 Date: 13th December 2013 Updated 17/12/13 Report No: 1 CA No: 1 STANDARD COMPANY PROCEDURES Waste management / oil sillage COMPANY GUIDANCE NOTES FINDING ISO 9001/ISO 14001/ISO 50001 Category : NON CONFORMANCE / CORRECTIVE ACTION Refer to Phil Cattell report dated 12th December 2013 Refer to Darren Nute (Cogenco) 11th December 2013 A waste oil tanker collection overfilled at collection time by Cogenco waste oil contractor driver. Contractor and Estates office staff attended site for immediate containment and cleaning. Containment measures stopped waste oil contaminating local drainage. Auditor: IMMEDIATE ACTION Site Representative: To be complete State proposed action(s) to be taken, and implementation date(s): by: Contractor and Estates office staff attended site for immediate containment and cleaning. Containment measures stopped waste oil contaminating local drainage. Closed out by: 05/12/13 05/12/13 To be complete State proposed action(s) to be taken, and implementation date(s): by: Closed out by: Site Representative: Phil Cattell CORRECTIVE ACTION Verify interceptors nearby to confirm no contamination of drainage system = = Survey ascertained the surface drainage duct was blocked stopping oil contamination to reach brook M Hubbard Jon Stranks 17/12/13 Temporary close duct to ensure safe drainage of oil In progress Confirm implementation of new interceptor End January14 (Reinstate lighting at side of Boiler house MH Obtain procedures from Cogenco and waste oil contractor describing waste oil collection J Cardinal 16/12/13 Issue memo stating closet(s) drain cover(s) must be used for all oil handling operation until oil storage and necessary procedures are updated M Stacey complete EF08-V01 Version 01 Page 1 of 2 Uncontrolled when printed Page 1 of 1 CORRECTIVE ACTION NOTICE Review + amend procedures and equipment to avoid repetition, All TBC Cogenco + OSL procedures EP-05-V01- Environmental Emergency Plan EP-04-V01-Environmental Procedure 4-Site Fuel & Oil Controls EP-03-V01-Environmental Procedure 3-Environmental Spill Controls Conduct internal Risk Assessment and provide BST’s with a written procedure M Hubbard February 14 Define and implement changes to estates equipment and drainage + Define and implement changes to spill kits All January 14 Review, update and deliver “oil spill tol box talk” and train necessary staff as appropriate ET-TBT-01-V01-Pollution Control Toolbox Talk ET-TBT-02-V01-Spill Control Toolbox Talk ET-TBT-03-V01-Environmental Storage and Use of Petrol, Diesel and Oils ET-TBT-04-V01-Water Pollution Prevention (Fuel & Oil) All January 14 Test the emergency procedure through a “desktop drill” to test updated procedures All March 14 Representative: COMPLETION The corrective actions have been satisfactorily implemented Auditor: Date: Comments: KEY Non-conformance = Corrective Action = The absence of a control system or significant non-compliance with an existing control system required by the procedures related to the Standard. A problem area that needs to be addressed. Memo to estates staff and contractors (to be displayed and communicated as appropriate) Dear colleagues and partners (Cogenco – OSL), Following the internal oil spill incident last 05th December 2013 we ask you to introduce immediate conservative measures until permanent solutions and procedures are in place. Although deliveries and collections are the direct responsibility of our contractors, the University has the duty to ensure all operations and safe and compliant with environmental legislation. All drain covers around oil handling operation must be in place before starting any delivery or collection The present instruction is to remain active until updated procedures and equipment are updated Mike Stacey Deputy Director of Estates EF08-V01 Version 01 Page 2 of 2 Uncontrolled when printed Page 1 of 1