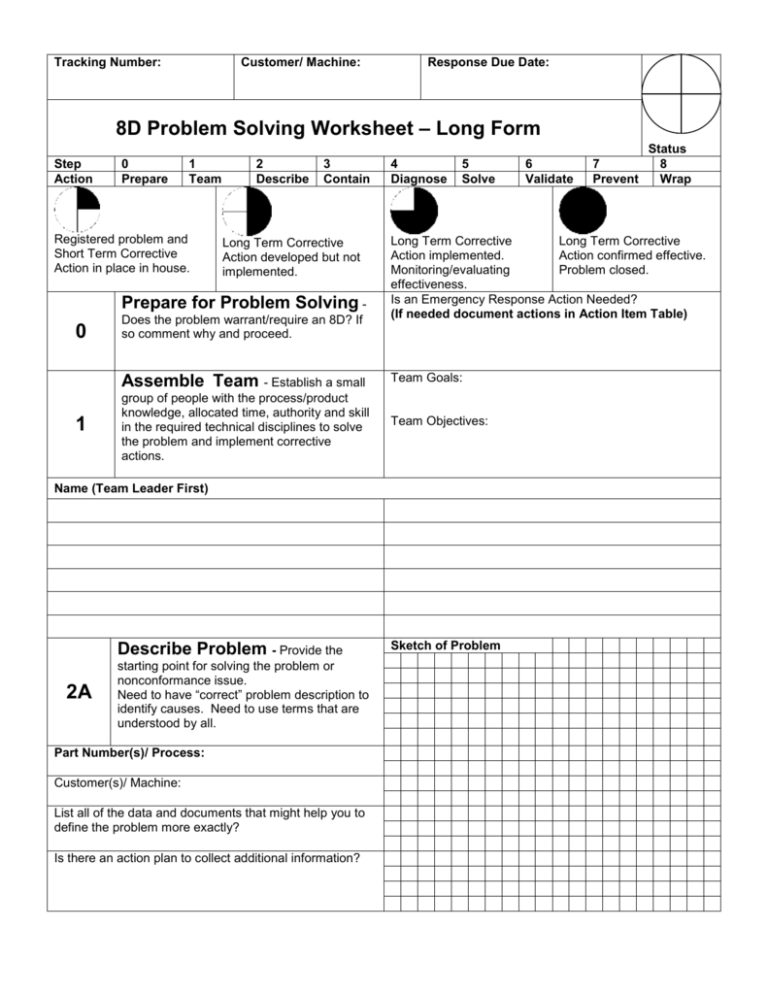

8D Problem Solving Worksheet - Long Form

advertisement

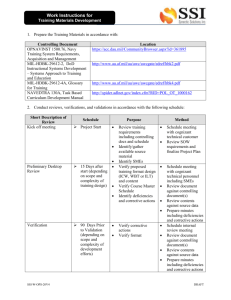

Tracking Number: Customer/ Machine: Response Due Date: 8D Problem Solving Worksheet – Long Form Step Action 0 Prepare 1 Team Registered problem and Short Term Corrective Action in place in house. 2 Describe 3 Contain Long Term Corrective Action developed but not implemented. Prepare for Problem Solving - 0 1 Does the problem warrant/require an 8D? If so comment why and proceed. 4 Diagnose 5 Solve Team Goals: group of people with the process/product knowledge, allocated time, authority and skill in the required technical disciplines to solve the problem and implement corrective actions. Team Objectives: Name (Team Leader First) 2A starting point for solving the problem or nonconformance issue. Need to have “correct” problem description to identify causes. Need to use terms that are understood by all. Part Number(s)/ Process: Customer(s)/ Machine: List all of the data and documents that might help you to define the problem more exactly? Is there an action plan to collect additional information? 7 Prevent Status 8 Wrap Long Term Corrective Long Term Corrective Action implemented. Action confirmed effective. Monitoring/evaluating Problem closed. effectiveness. Is an Emergency Response Action Needed? (If needed document actions in Action Item Table) Assemble Team - Establish a small Describe Problem - Provide the 6 Validate Sketch of Problem Who 2B IS IS NOT Who is affected by the problem? Who is not affected by the problem? Who first observed the problem? (internal/external) Who did not find the problem? What To whom was the problem reported? What type of problem is it? What does not have the problem? What has the problem? What could be happening but is not? What is happening? What could be the problem but is not? Do we have physical evidence of the problem in our possession? How Often How Much/ Many When Where Why Why is this a problem? Why is it not a problem? Is the process where the problem occurred stable? Where was the problem observed? Where could the problem be located but is not? Where does the problem occur? Where else could the problem be located but is not? When was the problem first noticed? When could the problem have been noticed but was not? When has it been noticed since? Quantity of problem? How many could have the problem but don’t? How Much is the problem causing in dollars, people, & Time? How big could the problem be but is not? What is the trend (continuous, random, cyclical)? What could the trend be but is not? Has the problem occurred previously? Problem Description - Combine the relevant information, this will be your Problem Description 2C Interim Containment Actions - Temporary actions to contain the problem and “fix” 3 until permanent correction is in place. (Note: Validate that the action taken works). Document Actions in the Action Item Table Diagnose Root Cause – Analyze for “Root Cause” of the problem. Identify and verify the Escape Point. 4A Brainstorm the possible causes of the problem (attach) 4A Cause and Effect Diagram (Attach copy of complete diagram(s) as appropriate) How made/operated? People Method Materials/Info Machine Environment Measurement Why did it get out/ fail? Problem (effect) People Method Environment Measurement Note on Diagram(s) circle the most likely contributors (3 max) from each side. 4B 5 – Why Analysis Ask – Why did this happen? Ask – Why did this happen? Ask – Why did this happen? Ask – Why did this happen? Ask – Why did this happen? Materials/Info Machine 5 6 7 7A Identify Solutions – Solutions that address and correct the root cause. Solutions determined to be the best of all the alternatives. Document and verify the Permanent Corrective Action (PCA) in the Action Item Table. Validation - Implement and validate to ensure that corrective action does “what it is supposed to do.” Detect any undesirable side effects. Document this on the Action Item Table. Return to root cause analysis, if necessary. Prevention (Design / Information Systems Review) - Determine what improvements in systems and processes would prevent problem from recurring. Ensure that corrective action remains in place and successful. Address Similar Systems - List similar systems. Assign Action Item and Individual to Follow Up to correct products/ machine with the potential for the same defect. Product/ Machine / Process / Action Assignee 7B Check if Applicable Review the following documents / systems. Completion Date Document Assignee Planned Actual Control Plans Engineering Master Specifications Manufacturing Set-up Sheet Manufacturing Check Sheet(s) QA Inspection Work Instructions QA Inspection Forms PM Procedure(s) Job Descriptions(s) Job Certifications/ Recertify 8 Congratulate Your Team! - Use all forms of employee recognition and document as necessary. Celebrate successful conclusion of the problem solving effort. Formally disengage the team and return to normal duties. Was the Problem Solving Worksheet Effective? Yes/No Signature/Title Date Action Item Table Action # Actions Containment/ Corrective Fault / Item Action Registered problem and Short Term Corrective Action in place in house. Implement and Verify Actions Verify Long Term Corrective Action developed but not implemented. Note: Copy this page and attach as often as necessary How Verified Action Assignee Long Term Corrective Action implemented. Monitoring/evaluating effectiveness. Planned Actual Status Long Term Corrective Action confirmed effective. Problem closed.