Root Cause Analysis Guidelines

advertisement

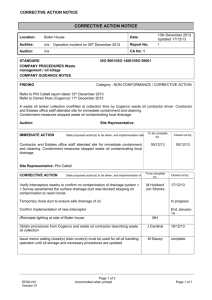

ENERGETIC MATERIALS Co. Root Cause Analysis Guidelines 1 ENERGETIC MATERIALS Co. Complete Problem Description The problem description is a narrative, using the initial problem description as the starting point. Who reported the problem? What is the specific problem or non-conformance, including actual data? What requirement is violated? What are part numbers, lot numbers, serial numbers? Where/when was the problem identified? 2 ENERGETIC MATERIALS Co. Immediate Containment Actions Define and implement containment actions to isolate potentially non-conforming material from internal or external customer until corrective/preventive action is implemented and verified effective. Containment actions must be implemented within 24 hrs. of notification. Consider internal, customer and supplier locations. Containment actions should be listed in chronological order. Containment actions should identify what took place, who took the action and when actions were taken. Potential risk of hardware previously produced must be evaluated as part of containment. 3 ENERGETIC MATERIALS Co. Verification of Containment Actions Describe the results of the containment actions (results of sorts, rework results, risk assessment, etc.). These actions must completely isolate the concern from the customer. 4 ENERGETIC MATERIALS Co. Root Cause and Verification A root cause analysis tool (5 Why, Fishbone, Pareto Analysis, DOE, etc) must be used. Avoid the symptom approach. The root cause is tested against the problem description. Verify the root cause by turning it on and off if possible. 5 ENERGETIC MATERIALS Co. Permanent Corrective Action and Verification Determine and implement permanent actions to prevent the root cause from recurring. Do not implement any permanent corrective action until the root cause has been determined and verified. The team should brainstorm potential corrective actions. Once corrective actions are identified, an implementation plan must be developed. What actions and who is responsible for the actions must be documented as well as expected completion dates. The verification plan must be included in the corrective action plan. As actions are implemented, they are recorded as verified with documented evidence. 6 ENERGETIC MATERIALS Co. Preventive Action and Verification Modify Management Systems, Operating Systems, Procedures, etc. required to prevent recurrence of the problem. What was done to ensure the problem will not recur in the future? What documentation was modified? Was the issue resolved enterprise wide? What Training is required? Was the training documented? What follow up is required? 7 ENERGETIC MATERIALS Co. Criteria for CAR Acceptance There is evidence that a root cause analysis tool was used. There is evidence that containment/potential risk has been evaluated. The CAR is filled out completely. There are completion dates and responsibilities clearly identified for containment and corrective actions. There is a plan to monitor and verify the effectiveness of corrective actions incorporated in the corrective/preventive action section. 8