1 Notes Outline Master

advertisement

Course overview and web page mechanics

http://www.stevens.edu/e344/e344_home.html

Assessment Performance Criteria Section 1 – Intro and Broad Goals

After an introductory course in Materials Science & Engineering, students will be able to:

1.1 Identify the major classes of engineering materials and give practical examples of

each

1.2 identify the materials properties characteristic of some engineering application and

use these to guide the selection from one of the major materials classes, or from within a

particular class, to best satisfy the needs of that application

1.3

show for a typical engineering material how processing, structure, and properties

are inter-related and how they define performance in an engineering application.

1.

2.

3.

4.

How big is an atom

what does an atom look like

how do atoms interact with each other (bonding; many-atom assemblies)

how do large numbers of atoms arrange themselves in space to form a solid?

Orders of magnitude

atto, femto, pico, (Angstrom), nano, micro, milli, (centi)

m, g, sec…

kilo, mega, giga, tera

Section 2: Atomic Structure and Bonding

Real Space 1: Planetary model of Na.

(how big is a sodium atom? Note 052212A)

- plum-pudding model (1902)

- Rutherford Au scattering experiment

(1911 – introduced concept of nucleus surrounded by electron clouds)

Real Space 2: Wave model of electrons in atoms (Real-space picture)

- Bohr model: electrons orbitals are standing waves

1

electron waves can move between discrete orbitals

w/well-defined energy changes

Energy Space: Energy-level diagram for hydrogen

-filled level

- empty levels

- forbidden levels

Schrodinger equation and quantum mechanics

- can predict the electron orbitals/wave functions

- introduces 4 quantum numbers

- Pauli exclusion principal

spdf notation to describe atomic electron configuration

Energy-level diagram for sodium

Transitions between energy levels

light emission/adsorption

X-Ray "" "" ""

Interactions between two sodium atoms

U(r) curves

Lennard-Jones potential

Information contained within U(r) curves

- equilibrium interatomic spacing

- melting temperature (deep potential energy well)

- thermal expansion (asymmetry)

l = T*l (see section 19.3 in Callister 8th)

Ex. Airplane: l = (50 m) * (2E-05 m/m-K) (100 K) = 10 cm

Real space planetary model of two bonded atoms: Molecular orbitals

Energy space picture: Conflict with Pauli exclusion principal

leads to splitting of valence electron energy levels

Hypothetical energy-level diagram for 2 Na atoms

- for 3 sodium atoms

- for 4 sodium atoms

- for N sodium atoms

Energy band diagram for Na:

2

- why is sodium (metal) a good electrical conductor?

- why is sodium (shiny) opaque to visible light?

14. Mg: overlapping conduction band and valence band

15. Energy band diagram for an insulator/semiconductor

- why is silica (E ~ 9 eV) a good electrical insulator?

- why is silica transparent to visible light?

Section 3: Metals, Alloys, and Elements of Structure

What is the difference between a metal and an alloy?

What are some examples of metals?

What are some of the important properties of metals?

What are some examples of where metals/alloys are used?

- what properties are important to these applications

What are the major ways in which we process (make objects out of) metals?

- deformation processing (exploits ductility)

- solidification processing (exploits accessible melting temperatures)

Crystallinity

Examples of crystalline minerals

Long-range order

2-D crystals;

- simple square, parallelograms,

- body-centered square (concept of a basis)

- # atoms per cell

Amorphous materials

- short-range order

Close-packed planes; close-packed directions

Stacking of close-packed planes

- ABABAB = HCP

3

- ABCABCABC = FCC

- stacking fault = one of many possible defects in a crystalline material

3-D unit cells

- FCC; SC; BCC

- APF

The 14 crystal classes

- a, b, c;

Miller index notation

- points

- directions

- planes

Diffraction

- Braggs Law

- calculation of atomic radius of Na (BCC

Isotropy; anisotropy

Defects in crystals

- point defects

- line defects

- planar defects

Section 4: Ceramics (and Semiconductors)

Definition of a ceramic: A ceramic material is an inorganic, nonmetallic, material

where two or more elements, typically a combination of a metal and a non-metal,

are bonded together by strong and directional ionic, covalent, or, more generally,

mixed ionic-covalent bonding.

Ionicity of a bond (Callister 8th eq. 2.10)

% ionic character = (1-exp(-[0.25]{Xa - Xb}2)) X 100

Ex) % ionicity of MgO = (1-exp(-[0.25]{1.2 – 3.5}2)) X 100 = 73.4

See Table 12.1 Callister

Examples of ceramics

Typical uses

Macroscopic properties of ceramic materials

4

Structure of ceramic materials

- crystalline unit cells

- cation-anion ratio

- charge neutrality

Three primary ways to process ceramic materials

- glass formation and the manipulation of viscous liquids

- powder processing

- processing by chemical reaction

Section 5: Polymers

Main (inter-related) categories:

Thermoplastics:

melt when (re)heated => melt processing of (viscous) liquids; recyclable

Thermosets:

shaped and then cured; do not melt when reheated (reusable/recyclable)

Rubbers:

High elastic deformation

Gels:

Designed to interact with solvents (hydrogels interact with water)

-------Polymer = many units

Monomer unit of PE

Molecular weight

Free radical polymerization of PE

Conformation of a PE molecular

Sp3 bonding

Sp2 bonding

Show/pass ball and stick model of PE

Rope demo of conformation

Rg: How big is a polymer molecule?

Other types of monomer units

-PVC

5

-PP

-PS

-PTFE

-PMMA

-PMAA

-PAA

Homopolymers; blends; and copolymers

- block, alternating, random

- macrophase vs microphase separation

Tacticity

Branching

viscosity

Tg

crystalline vs amorphous

Condensation polymerization

- nylon

- proteins and natural polymers

Rubber

- lightly crosslinked thermoplastic (vulcanization)

- natural; synthetic

- example = butadiene

- possible to have rubber without covalent crosslinks

Gels

- lightly crosslinked and designed to interact with solvent

- hydrogels are designed to interact with water

Thermosets

- heavily crosslinked polymer

- typically crosslinked during synthesis of (short) molecules rather than linking of

macromolecules (like rubber)

- example = epoxy

Recycling vs. reusing

If time permits: Composite materials (ch. 16 in Callister)

6

Composite material = any multiphase material (natural or, more commonly,

synthetic) exhibiting a significant portion of the properties of the constituent phases

in order to realize a composite material with better properties than either

constituent alone.

Metal-matrix

Ceramic-matrix

Polymer-matrix…

Filler = glass, carbon, high-performance polymer fiber (alternately particulate).

Matrix = epoxy or other polymer

Nanocomposites

Section 8: Mechanical Properties

definition of engineering tensile stress, tensile strain, poisson ratio

True stress/strain

Shear stress/strain

Tensile test

ASTM = American Society for the Testing of Materials

Information from a tensile test (y, E, T, %elongation, toughness, resilience)

Reconstructing stress-strain diagram from 4 parameters

Hardness

Estimate of E from 1st principles (Cu)

Estimate of yield strength of Cu from 1st principles.

Dislocations

- types; draw an edge dislocation

- mathematical representation of a dislocation

- burger's vector, line direction

Slip systems

7

Strengthening mechanisms

- strain hardening

- grain-boundary strengthening and Hall-Petch

- solid soln strengthening

- ppt hardening

Failure

1. Ductile

2. Brittle

stress concentrators:

a 1/ 2

m 2o

t

where m = max stress in front of crack tip

o = magnitude of applied tensile stress

a = crack half width

t = radius of curvature of elliptical crack

Non destructive evaluation (NDE)

KIC = Y crit(*a)1/2

3. Fatigue

cyclic loading; stress amplitude

S/N curve (see figure 8.19); fatigue limit; fatigue strength

Vignette – femoral nail

4. Creep

Qc

eq. 8.20 in Callister 8th

RT

Ýs K 2 n exp

8

E

Ýs K 2 n exp c

or:

kB T

Section 9: Fundamentals of Phase Transformations

Case Study 1: Recovery, Recrystallization, and Grain Growth

Cold rolling

- decrease plate thickness

- changes shape of grains from ~equiaxed to ~ pancaked.

- increases dislocation density

- decrease ductility

Changes upon annealing

- define annealing

- define what high temperature means (already done in discussion of creep)

- high temperature enables atomic motion (i.e. diffusion)

Recovery = rearrangement of dislocations to minimize energy

Recrystallization of new, equiaxed, low dislocation density grains

energetic driving force = lowering of strain energy

Grain growth – grain size increases

- energetic driving force = lowering of total grain-boundary energy

difference between cold work and hot work

Fundamentals of Nucleation

Volume Free Energy

Surface Energy

Homogeneous nucleation

Heterogeneous nucleation

Fundamentals of Diffusion

Concentration profiles

9

Fick's first law

- flux is proportional to the concentration gradient

- proportionality constant = D

- units on D

Values of Diffusivity

Fick's 2nd law

erf soln

vacancy mechanism of diffusion

Temperature dependence of diffusion

bulk, interstitial, surface, grain-boundary diffusion

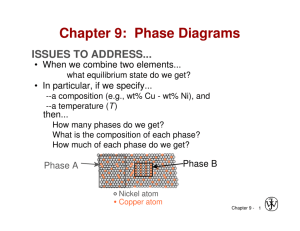

Section 10: Phase Diagrams

definition of a phase

a homogeneous and mechanically separable

portion of matter with a well-defined chemical composition

ex: granite and other rocks

Phase diagram as a map of the phases stable

tells what phase or phases are stable at given T, P, composition, etc.

water P-T diagram

- ice skates

- density of solid < density of liquid (ice floats; unlike most metallic systems]

Solid Solutions and the Hume-Rothery Rules [Page 95 in Callister 8th]

Cu – Ni diagram: Example of an isomorphous alloy system

Pb-Sn eutectic diagram

- stuff that can be identified immediately from diagram

- example of cooling from (PB) phase field into 2-phase field

- example of eutectic solidification

- example of hypo/hyper eutectic solidification

10

Phase diagrams indicating very limited solubility

- water-salt (p. 301 in Callister 8th)

- Sn-Bi

phase diagrams with compounds

ex: Ge-Te phase-change optical storage

The Fe-Fe3C and Fe-C phase diagrams

- polymorphism

- austenite

- ferrite

- cementite

Limits of solubility

- why is carbon so much more soluble in FCC than in BCC?

Eutectoid rxn vs Eutectic rxn

Example of a 1080 steel

- Pearlite (see figs 9.27 and 10.15 in Callister 8th for micrographs)

- fine pearlite (forms by faster cooling through eutectoid temp)

- coarse pearlite (forms by slower cooling through eutectoid temp)

- spherodite (forms by very slow cooling thru eutectoid temp

or by annealing just below eutectoid temp).

A sqrt(Dt) analysis indicates that C can diffuse in Fcc at 1000 K for ~500 microns.

Example of a 1040 steel (note fig 9.30 in Callister 8th shows micrograph)

hypo eutectoid alloy

proeutectoid ferrite forms

eutectoid composition transforms to pearlite w/ remaining proeutectoid

ferrite

Fe-Fe3C phase diagram

- Hardness as a function of wt%C

- pearlitic microstructure

- spherodized microstructure

- martensitic microstructure

Callister 8th page 362: Martensite = non-equilibrium, single phase structure that

results from a diffusionless transformation of austenite.

Quenching from the gamma phase field limits carbon diffusion

11

FCC wants to transform to BCC but can't because of carbon

Instead, FCC transforms to BCT (distorted BCC) via "Bain transformation"

Carbon stuck in former octahedral site (super saturated)

TTT and CCT diagrams

Hardenability = how easily an alloy forms martensite (see Glossery in Callister)

Jominy test (QUIZ???)

Tempering

How to select a set of kitchen knives; Samurai sword

PPT hardening and the Al-Cu phase diagram

see figs. 11.24 (Al-Cu phase diagram); 11.22 (schematic heat treatment) and

11.27 (hardness curves)

Temper designations

12