(kefiran/WPI)-MMT ratios were 100:0, 99:1, 97:3 and 95:5 (w/w)

advertisement

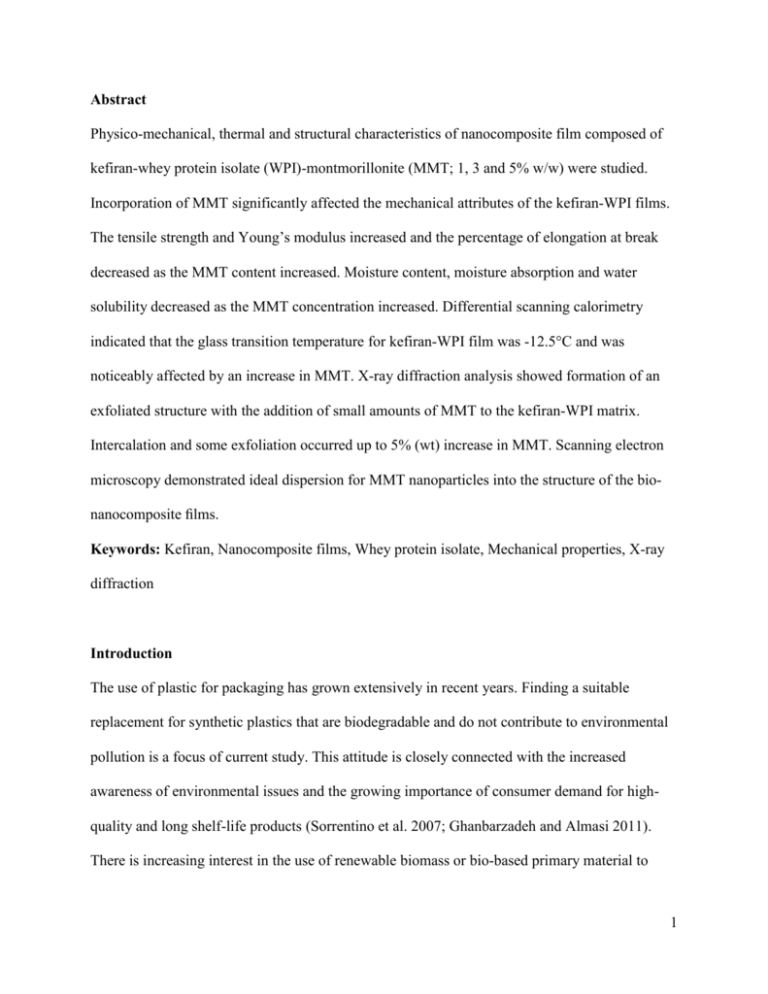

Abstract Physico-mechanical, thermal and structural characteristics of nanocomposite film composed of kefiran-whey protein isolate (WPI)-montmorillonite (MMT; 1, 3 and 5% w/w) were studied. Incorporation of MMT significantly affected the mechanical attributes of the kefiran-WPI films. The tensile strength and Young’s modulus increased and the percentage of elongation at break decreased as the MMT content increased. Moisture content, moisture absorption and water solubility decreased as the MMT concentration increased. Differential scanning calorimetry indicated that the glass transition temperature for kefiran-WPI film was -12.5°C and was noticeably affected by an increase in MMT. X-ray diffraction analysis showed formation of an exfoliated structure with the addition of small amounts of MMT to the kefiran-WPI matrix. Intercalation and some exfoliation occurred up to 5% (wt) increase in MMT. Scanning electron microscopy demonstrated ideal dispersion for MMT nanoparticles into the structure of the bionanocomposite films. Keywords: Kefiran, Nanocomposite films, Whey protein isolate, Mechanical properties, X-ray diffraction Introduction The use of plastic for packaging has grown extensively in recent years. Finding a suitable replacement for synthetic plastics that are biodegradable and do not contribute to environmental pollution is a focus of current study. This attitude is closely connected with the increased awareness of environmental issues and the growing importance of consumer demand for highquality and long shelf-life products (Sorrentino et al. 2007; Ghanbarzadeh and Almasi 2011). There is increasing interest in the use of renewable biomass or bio-based primary material to 1 decrease environmental pollution caused by food packaging (Gonzalez-Gutierrez et al. 2010; Ghasemlou et al. 2011a). Edible and biodegradable film is primarily composed of polysaccharides, proteins and lipids alone or in combination. To make them appropriate for packaging, the film should be a suitable gas- and aroma-barrier and possess mechanical properties that prevent quality deterioration and increase the shelf life of food products (Kristo et al. 2007; Ghanbarzadeh and Oromiehi 2008). Several studies have examined film based on polysaccharides like chitosan (Ojagh et al. 2010), kefiran (Ghasemlou et al. 2011b, c), plant-source starch (Almasi et al. 2010; Gao et al. 2011), and proteins such as whey (Sothornvit et al. 2009), zein (Ghanbarzadeh et al. 2006), gluten (Gontard et al. 1993; Gontard et al. 1994) and agar (Rhim 2011). These investigations have indicated that the tested polysaccharides and proteins were promising materials for sustainable green packaging. Kefiran as a microbial and water-soluble polysaccharide obtained from the flora of kefir grains and contains approximately equal amounts of glucose and galactose. It improves the viscosity and viscoelastic properties of acid milk gels. This polysaccharide is also used in the food industry as a texturing and gelling agent (Piermaria 2008; Ghasemlou et al. 2011a-c). Kefiran has functional advantages over other polysaccharides, such as antibacterial, antifungal and antitumor properties (Cevikbas et al. 1994). Recent studies have reported that this exopolysaccharide can be easily isolated from grains of deproteinized whey at high yields (Rimada and Abraham 2006). In addition, the mechanical and physical properties of film made from kefiran exhibit good potential as an edible film in the food and packaging industries (Ghasemlou et al. 2011a-c). 2 Whey protein is a by-product of cheese making and a well-known source of biodegradable film. Whey protein is widely used food supplements with high nutritional value and the ability to form gels, emulsions and foams. This functionality makes whey protein good candidates for the production of biodegradable film (Zhou et al. 2009). Although whey protein film can act as an excellent oxygen barrier at low or intermediate relative humidity (RH), film containing whey proteins without modification has high water-vapor permeability (WVP) because of the high proportion of hydrophilic amino acids in its structure and its relatively poor mechanical properties (Osés et al. 2009). Unfortunately, the use of protein/polysaccharide-based film for food packaging has been limited because of its weak barrier and mechanical properties. A number of methods have proposed to improve the tensile strength and barrier properties, including the addition of plasticizing agents (Ghanbarzadeh and Almasi 2011), blending of biopolymers or other materials in their formulation (Ghanbarzadeh and Almasi 2011). Nanocomposites are a promising option to improve the thermal, mechanical and barrier properties of films made from biodegradable biopolymers (Avella et al. 2005). Polymer-clay nanocomposites are the latest stages of polymer technology. The incorporation of inorganic or natural fibers into polymers to create nanocomposites can improve some properties of biodegradable polymers (Cyras et al. 2008). Montmorillonite (MMT) is a nano-scale clay of particular interest because it is economical, environmentally-friendly, and easily accessible in large amounts (Choi et al. 2003; Almasi et al. 2010). MMT is a hydrated alumina-silicate layered clay consisting of 10 Å thin layers with an octahedral alumina sheet sandwiched between two tetrahedral silica sheets. Its high surface area and large aspect ratio make it suitable for reinforcement purposes (Xu et al. 3 2005; Cyras et al. 2008). Small amounts of MMT can significantly improve the properties of kefiran biopolymer and whey protein isolate (WPI). Since film produced using biopolymers are brittle, good plasticizers are required to offset this disadvantage (Ghanbarzadeh and Almasi 2011). Glycerol is the most common plasticizer in the preparation of edible and biodegradable films. An appropriate proportion of plasticizer is required in the film solution to decrease intermolecular forces and water-vapor transmission through the edible and biodegradable film. The concurrent presence of these compounds, however, should not produce adverse effects on the mechanical and optical properties of the film (Srinivasa et al. 2007; Gonzalez-Gutierrez et al. 2010; Ghasemlou et al. 2011a-c). No specific investigation on the effects of MMT content on the properties of kefiran-WPI biocomposite film has been observed. The aim of the present study was to study the physical, mechanical, thermal and structural properties of glycerol plasticized kefiran-WPI-MMT bionanocomposites. Materials and Methods Materials The kefir grains were kept in skimmed milk at room temperature and the medium was exchanged daily for new culture to maintain the viability of the grain. The grains were considered active after seven consecutive days. Whey protein isolate (WPI, 90% protein (wt)) was purchased from Arla Food Ingredient (Tokyo, Japan). Glycerol, calcium nitrate, calcium sulfate, and calcium chloride (analytical grade) were purchased from Merck Chemical Co. (Darmstadt, Germany). Unmodified natural MMT (Cloisite Na+) with a density of 2.6 g ml-1 was purchased from Southern Clay Products (Gonzalez, TX). 4 Isolation and purification of kefiran Kefiran exopolysaccharide was extracted from the kefir grains using the method described by Piermaria et al. (2009). In brief, a specific quantity of kefir grain was added to boiling water (1:10 w/v) and stirred occasionally for 1 h. After reaching uniformity, the mixture was centrifuged (Sigma 3-16 k; Frankfurt, Germany) at 10,000 × g for 15 min at 20°C. An equal volume of chilled ethanol was added to the mixture to precipitate the secretion of polysaccharides in the supernatant of the centrifuged samples. The mixture was kept at 20°C overnight and the pellets were collected by centrifuging at 10,000 × g for 20 min at 4°C. The precipitates were re-dissolved in hot distilled water and the precipitation method was repeated twice. The resulting solution was concentrated, yielding a crude polysaccharide. The samples were tested for the absence of other sugars and proteins using high-performance liquid chromatography and phenol-sulfuric acid, respectively (Dubois et al. 1956). Film preparation A 5% (w/v) WPI solution was prepared by dispersing 5 g of WPI in 100 ml of distilled water, heated it in a water-bath at 90°C for 30 min and then rapidly cooling on ice. The kefiran solution (5% w/v) was prepared by weighing the amount of film-forming solution under constant magnetic stirring for 15 min. The kefiran-WPI composite film was prepared by the mixing the kefiran and WPI solutions in equal amounts (50:50 (v/v)). The films prepared without plasticizer were brittle and cracked on the casting plates during drying; thus, glycerol plasticizer (35% of total solid weight) was incorporated into the film-forming solution to achieve a more flexible film. Stirring was continued for a further 15 min 5 after addition of the plasticizer. The solution was maintained in a vacuum oven at 30°C for 30 min to remove most of the air bubbles that developed during stirring. The MMT was dispersed in distilled water by sonication for 1 h at room temperature. The MMT dispersion was added to the aqueous dispersion of kefiran-WPI and stirring was continued for 1 h. The (kefiran/WPI)-MMT ratios were 100:0, 99:1, 97:3 and 95:5 (w/w) relative to dry kefiran-WPI. About 70 ml of the sample was cast onto flat, leveled, non-stick teflon plates and were held at room temperature and room RH for 18 h to set. Once set, they were peeled off the casting surface and stored in plastic bags inside desiccators at 25±1 °C for further testing. All treatments were made in triplicate. Physical characteristics Film thickness The thickness of the film was measured using an Alton M820-25 hand-held micrometer (China) having a sensitivity of 0.01 mm. Measurement of the thickness was done at 10 randomly selected points on each test specimen and the average of all tests was recorded. X-ray diffraction X-ray diffraction of the kefiran-WPI film, MMT and nanocomposites at different percentages were recorded and analyzed using an X'Pert MPD diffractometer (Philips Co., Holland). The samples were exposed to an x-ray beam generated with radiation Cu Kα (λ=1.542 Å, 40 kV and 30 mA). All experiments were carried out in reflection mode at ambient temperature with 2𝜃 of between 0° and 40° and a scanning rate of 1°/min-1. 6 Mechanical properties The tensile strength (TS), elongation at break (EB) and Young’s modulus (YM) were evaluated using a Testometric M350-10CT (Testometric Co., Ltd., Rochdale, Lancs., England) according to ASTM standard D882-02 (ASTM 1995). The film was cut into rectangular strips 100 mm long and 10 mm wide. All specimens were 50% ± 5% RH for 48 h in a desiccator using saturated calcium nitrate solution. The films were fixed with an initial grip separation of 50 mm and stretched at a cross-head speed of 10 mm min-1. A microcomputer was used to record the stress-strain curves. TS was calculated by dividing the maximum load on the film before failure by the cross-sectional area of the initial film specimen. EB was defined as the percentage of change in the length of the specimen when compared to the original length between grips. YM was determined by dividing the stress by the strain. At least three replicates of each type of film were tested. Moisture content The moisture content (MC) of the specimens was determined with three replicates by measuring the weight loss of the film before and after drying in a laboratory oven (Blue M Electric, Blue Island, IL) at 105±1 °C until a constant weight was achieved. Moisture absorption Moisture absorption (MA) was measured according to a modified version of the method suggested by Almasi et al. (2010). Dried 20 mm × 20 mm sheets of film were first conditioned at 0% RH (calcium sulfate) for 24 h. After weighing, they were conditioned in a desiccator containing calcium nitrite saturated solution at 25°C to ensure a RH of 55%. The samples were 7 weighed at desired intervals until the equilibrium was reached. The MA of the samples was calculated as: W W0 MA t W0 (1) where Wt and W0 are the weights of the sample for time (t) at 55% RH and the initial weight of the sample, respectively. All measurements were performed in triplicate. Water solubility Water solubility (WS) was defined as the ratio of water-soluble dry matter in the film that dissolved after immersion in distilled water (Gontard et al. 1994). To determine WS, a film specimen was cut from each film, dried at 105±1 °C to a constant weight in a laboratory oven and weighed to determine the initial dry weight (m1). The WS of the film sample was measured by immersion assay in 50 ml of distilled water after periodic stirring for 6 h at 25°C. The remaining pieces of film were removed and dried at 105±1 °C until a constant weight (m2) was achieved. The WS of the film was calculated as: WS = m1 m2 100 m1 (2) Thermal properties The thermal properties of the composite film were measured using differential scanning calorimetry (DSC) (Mettler Toledo, DSC1 Star System). The thermal properties of kefiran-WPI composite at different MMT contents indicate the structure and interactions between kefiranWPI polymer, MMT and the plasticizer (Ghasemlou et al. 2011a). Small pieces of each sample were weighed and placed into the DSC pan. The reference value was an empty pan. The glass 8 transition temperature (Tg) of the film was measured at a heating scan rate of 10°C min-1 from 50 to 250 °C. The midpoint temperature was identified as the step-down shift at baseline of the change in heat capacity upon glass transition. The melting point (Tm) of the film was determined using nitrogen gas as the purge gas at a flow rate of 20 ml min-1. Microstructural characterization Scanning electron microscopy (SEM) was used to study the surface and cross-section of the kefiran-WPI film and the nanocomposites. The SEM measurements were carried out by a scanning electron microscope (Oxford Instruments INCA Penta FET×X3)The dried samples were fractured in liquid nitrogen, mounted on aluminum stubs using double-stick tape and coated with a layer of gold, allowing surface visualization using an accelerated voltage of 15.0 kV. The samples were photographed at 90° from the surface to observe a cross-section of the film. Statistical analysis Analysis was based on a completely randomized design using ANOVA on SPSS software. Duncan’s multiple range test was used to compare the means of film characteristics at p = 0.05. Results and Discussion X-ray diffraction X-ray diffraction (XRD) was used to determine the gallery height (d-spacing distance) of the MMT particles and investigate dispersion of the MMT layers. The d-spacing was determined by the diffraction peak in the XRD patterns and is expressed by Bragg's equation (λ = 2d001sinθ), where d001 is the interplanar distance of (001) diffraction face, θ is the diffraction position, and λ 9 is the wavelength. During intercalation, insertion of polymer molecules into the MMT galleries forced the layers apart and increased the d-spacing. This created a shift in the diffraction peak toward lower angles (Xu et al. 2005). The XRD patterns for the kefiran-WPI film, MMT, and the composites are shown in Fig. 1. As shown, the kefiran-WPI had a semi-crystalline nature. MMT showed a characteristic peak at 2θ = 8.23° (d001 = 10.74 Å). The reflection peak disappeared with the addition of 1% and 3% MMT to the kefiran-WPI solution, indicating formation of an exfoliated structure that was disordered and not detectable by XRD (Xu et al. 2005). It shifted toward a lower angle at about 6.99° (d001 = 12.63 Å) and broadened after formation of the nanocomposite with 5% MMT, suggesting that the kefiran, WPI polymer chains, or both permeated the sheets of MMT, forming an intercalated kefiran-WPI-MMT bio-nanocomposite without complete exfoliation. This phenomenon can be attributed to the strong polar interaction between the hydroxyl groups present in the polymer chain and the silicate layers (Choi et al. 2003; Xu et al. 2005). Cyras et al. (2008) reported that the diffraction peak of MMT (Cloisite Na+) shifted toward lower angles regardless of the clay content of their starch/clay nanocomposite film. A comparison of the d001 peaks of the kefiran-WPI and bio-nanocomposite shows that the angles of the diffraction peaks for the film specimens were not noticeably affected by changes in the MMT concentration. Since the majority matrix of the film was kefiran and WPI, a similar XRD pattern was observed for nanocomposite film at all MMT concentrations; only the intensity of the diffraction peaks changed (Rhim 2011). This can be probably attributed to an increase in chain regularity in amorphous regions and an increase in the degree of crystallinity. Mechanical properties of the film 10 Since a polymeric material such as film may be subject to stress during use, determination of its mechanical properties involves scientific, technological, and practical aspects (Tang et al. 2008). Table 1 shows the EB, TS and YM of film equilibrated at 50% RH and 25°C. The incorporation of MMT significantly affected the TS and EB levels of kefiran-WPI and kefiran-WPI-MMT nanocomposite film at different MMT contents (p < 0.05). The TS of the kefiran-WPI composite film was 6.54 ± 0.16 MPa. When the MMT content in the kefiran-WPI solution increased from 1% to 5%, the TS increased from 6.56 ± .03 MPa to 11.10 ± .10 MPa. As the MMT content increased from 0% to 5% (wt), the YM increased from 105.33 to 310.66 MPa. This behavior is a likely a result of resistance exerted by the MMT, with a high surface area, and to the orientation and aspect ratios of the intercalated silicate layers (Cyras et al. 2008). In addition, the stronger interfacial interaction of the hydrogen and ionic bonds between the polymer matrix and the layered silicate increased the modulus (Rhim 2011). It should be noted that TS did not increase at all increases in MMT. At higher percentages, the possibility of exfoliation of MMT in the bio-nanocomposite film decreased and agglomeration of MMT may have occurred (Xu et al. 2005). In general, improvement in the mechanical properties of bio-nanocomposite film can be attributed to the high aspect ratio and rigidity caused by the strong affinity between the biopolymer and MMT (Sothornvit et al. 2010). The decrease in EB with the increase in MMT content is shown in Table 1. Layered silicate as a mechanical reinforcement of kefiran-WPI decreased polymer flexibility. The TS of film containing 5% MMT was comparable to those of the low density polyethylene and polyvinylidene chloride currently used in food packaging applications. EB values for these plastic films range from 100% to 900%. These values are much higher than those for kefiran- 11 WPI-MMT film (42.62% to 76.52%). The lower EB value may limit the application of kefiranWPI-MMT film as a food packaging material (Kumar et al. 2010). Moisture absorption, water solubility and moisture content An important drawback to the use of biopolymer material is MA; thus, any increase in water resistance is very important (Tang et al. 2008). Table 2 shows the MA of the kefiran-WPI and kefiran-WPI-MMT film. As seen, the MA of the kefiran-WPI-MMT film decreased as the MMT content increased. The MA of the kefiran-WPI was 16.98%, while the kefiran-WPI-MMT film showed the lowest MA, at about 5.67%. This can be attributed to the presence of strong hydrogen bonds between the MMT and kefiran and WPI molecular chains that decrease the diffusion speed of water molecules into the material and improve water resistance. These results were similar to those reported by Cyras et al. (2008), who observed a decrease in water absorbed by nanocomposites made with MMT. Solubility is an important functional property of biopolymer-based film and is related to the hydrophilicity of the materials (Ghasemlou et al. 2011a; Li et al. 2011). MC is also related to the total void volume of water molecules in the network microstructure of the film (Li et al. 2011). Table 2 shows that the MC and WS of kefiran-WPI-MMT were lower than for the kefiran-WPI film. The MC and WS of the kefiran-WPI-MMT film decreased as the MMT content increased. Thermal characteristics of the film DSC of the kefiran-WPI film at different MMT contents was performed to better understand the structure and interaction between the polymer and MMT. Fig. 2 shows the DSC curves of these 12 films. The glass transition temperature (Tg) is the temperature at which a material undergoes a structural transition from an amorphous solid state (glassy state) to a more viscous rubbery state (Ghasemlou et al. 2011a). In all cases, only one glass transition point followed by an endothermic peak was observed. The Tg and melting temperature (Tm) are listed in Table 3. All Tg values were in the range of -3.83°C to -12.50°C depending on MMT content; however, these values increased as the MMT content increased. It is assumed that the silicate layers act as physical cross-linking sites and decrease the activity of the kefiran-WPI matrix. In addition, kefiran-WPI chains that intercalate into the interlayers of MMT are restricted by the MMT sheets (Zheng et al. 2002). The DSC thermograms exhibited sharp endothermic peaks at 82-91°C that are ascribed to the melting of kefiran-WPI during retrogradation. Tm of the nanocomposite increased when the MMT nanoparticle content increased. The Tm peak for the kefiran-WPI film was 82.33°C; that of the kefiran-WPI film with 5% MMT was 91.55°C. This was mainly a result of nanodispersion of MMT sheets in the kefiran-WPI matrix and decreased mobility of the biopolymer chains (Zheng et al. 2002; Almasi et al. 2010). Microstructure of the film SEM allowed visualization of the surface and cross-section topography of the film specimens. Figs. 3 and 4 show the electron scanning micrographs of the outer surfaces and cross-sections, respectively, of the kefiran-WPI composite film at different MMT concentrations. As seen, the surface and cross-section of kefiran-WPI are relatively smooth and homogeneous without pores, cracks or air bubbles (Figs. 3a and 4a). At 1-5% MMT, the MMT was well-dispersed in the bionanocomposite film (Fig. 3b-d) and improved the properties of the composites. Similar results 13 have been reported for surface and cross-section micrographs of soy protein isolate-MMT film at different MMT concentrations (Kumar et al. 2010). The fracture cross-section of the film also became rougher as the MMT content increased (Fig. 4b-d). Conclusion Exfoliated nano-structures formed with the addition of small amounts of MMT to a kefiran-WPI matrix. The mechanical properties of kefian-WPI-based film were greatly influenced by the addition of MMT; the magnitude of change was dependent on MMT content. The bionanocomposite film showed the lowest solubility at 5% MMT. The MA and MC of the film samples decreased with the addition of MMT. DSC thermograms indicated that the glass transition and melting temperatures significantly increased as MMT content increased from 1% to 5%. References Almasi H, Ghanbarzadeh B, Entezami AA (2010) Physicochemical properties of starch-CMCnanoclay biodegradable films. Int J Biol Macromol 46: 1-5. ASTM (1995) Standard test methods for water vapor transmission of material. In Annual book of ASTM. Philadelphia: American Society for Testing and Materials. Avella M, de Vlieger JJ, Errico ME, Fischer S, Vacca P, Volpe MG (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93: 467–474. Cevikbas A, Yemni E, Ezzedenn FW, Yardimici T, Cevikbas U, Stohs SJ (1994) Antitumoural, antibacterial and antifungal activities of kefir and kefir grains. Phytother Res 8: 78-82. 14 Choi WM, Kim TW, Park OO, Chang YK, Lee JW (2003) Preparation and characterization of poly(hydroxybutyrate-co-hydroxyvalerate)–organoclay nanocomposites. J Appl Polym Sci 90: 525-529. Cyras VP, Manfredi LB, Ton-That MT, Va´zquez A (2008) Physical and mechanical properties of thermoplastic starch/montmorillonite nanocomposite films. Carbohyd Polym 73: 55–63. Gao W, Dong H, Hou H, Zhang H (2011) Effects of clays with various hydrophilicities on properties of starch–clay nanocomposites by film blowing. Carbohyd Polym 88: 321-328. Ghanbarzadeh B, Almasi H (2011) Physical properties of edible emulsified films based on carboxymethy cellulose and oleic acidl. Int J Biol Macromol 48: 44–49. Ghanbarzadeh B, Oromiehi AR (2008) Biodegradable biocomposite films based on whey protein and zein: Barrier, mechanical properties and AFM analysis. Int J Biol Macromol 43: 209–215. Ghanbarzadeh B, Oromiehie A, Musavi M, Razmi E, Milani J (2006) Effect of polyolic plasticizers on rheological and thermal properties of zein resins. Iran Polym J 15: 779-787. Ghasemlou M, Khodaiyan F, Oromiehie A (2011a) Physical, mechanical, barrier, and thermal properties of polyol-plasticized biodegradable edible film made from kefiran. Carbohyd Polym 84: 477-483. Ghasemlou M, Khodaiyan F, Oromiehie A,Yarmand MS (2011b) Development and characterisation of a new biodegradable edible film made from kefiran, an exopolysaccharide obtained from kefir grains. Food Chem 127: 1496-1502. Ghasemlou M, Khodaiyan F, Oromiehie A, Yarmand MS (2011c) Characterization of edible emulsified films with low affinity to water based onkefiran and oleic asid. Int J Biol Macromol 49: 378-384. 15 Gontard N, Duchez C, Cuq B, Guilbert S (1994) Edible composite films of wheat gluten and lipids: Water vapour permeability and other physical properties. Food Sci Technol 29: 39-50. Gontard N, Guilbert S, Cuq JL (1993) Water and glycerol as plasticizers affect mechanical and water vapor barrier properties of an edible wheat gluten film. J Food Sci 58: 206-211. Gonzalez-Gutierrez J, Partal P, Garcia-Morales M, Gallegos C (2010) Development of highlytransparent protein/starch-based bioplastics. Bioresour Technol 101: 2007-2013. Kristo E, Biliaderis CG, Zampraka A (2007) Water vapour barrier and tensile properties of composite caseinate-pullulan films: Biopolymer composition effects and impact of beeswax lamination. Food Chem 101: 753-764. Kumar P, Sandeep KP, Alavi S, Truong VD, Gorga RE (2010) Preparation and characterization of bio-nanocomposite films based on soy protein isolate and montmorillonite using melt extrusion. J Food Eng 100: 480-489. Li Y, Jiang Y, Liu F, Ren F, Zhao G, Leng X (2011) Fabrication and characterization of TiO2/whey protein isolate nanocomposite film. Food Hydrocolloid 25: 1098-1104. Ojagh SM, Rezaei M, Razavi SH, Hosseini SM (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122: 161-166. Osés J, Fabregat-Vázquez M, Pedroza-Islas R, Tomás AS, Cruz-Orea A (2009) Development and characterization of composite edible films based on whey protein isolate and mesquite gum. J Food Eng 92: 56-62. Piermaria JA, Pinotti A, Garcia MA, Abraham AG (2009) Films based on kefiran, an exopolysaccharide obtained from kefir grain: Development and characterization. Food Hydrocolloid 23: 684-690. 16 Piermaria JM (2008) Gelling properties of kefiran, a food-grade polysaccharide obtained from kefir grain. Food Hydrocolloid 22: 1520-1527. Rimada PS, Abraham AG (2006) Kefiran improves rheological properties of gluconolactone induced skim milk gels. Int Dairy J 16: 33-39. Rhim JW (2011) Effect of clay contents on mechanical and water vapor barrier properties of agar-based nanocomposite films. Carbohyd Polym 86: 691-699. Sorrentino A, Gorrasi G, Vittoria V (2007) Potential perspectives of bio-nanocomposites for food packaging applications. Trend Food Sci Technol 18(2): 84-95. Sothornvit R, Hong SI, An DJ, Rhim JW (2010) Effect of clay content on the physical and antimicrobial properties of whey protein isolate/organo-clay composite films. LWT - Food Sci Technol 43: 279-284. Sothornvit R, Rhim JW, Hong SI (2009) Effect of nano-clay type on the physical and antimicrobial properties of whey protein isolate/clay composite films. J Food Eng 91: 468-473. Srinivasa PC, Ramesh MN, Tharanathan RN (2007) Effect of plasticizers and fatty acids on mechanical and permeability characteristics of chitosan films. Food Hydrocolloid. 21: 11131122. Tang S, Zou P, Xiong H, Tang H (2008) Effect of nano-SiO2 on the performance of starch/polyvinyl alcohol blend films. Carbohyd Polym 72: 521-526. Xu Y, Ren X, Hanna MA (2005) Chitosan/clay nanocomposite film preparation and characterization. J Appl polym Sci 99: 1684-1691. Zheng JP, Li P, Ma YL, Yao KD (2002) Gelatin/montmorillonite hybrid nanocomposite. J Appl Polym Sci 86: 1189-1194. 17 Zhou JJ, Wang SY, Gunasekaran S (2009) Preparation and characterization of whey protein film incorporated with tio2 nanoparticles. J Food Sci 74: 50-55. Figure Legends Fig. 1 XRD patterns for the kefiran-WPI, MMT and their composites Fig. 2 Thermogram of the kefiran-WPI films containing different amounts of MMT Fig. 3 SEM micrographs of surfaces of kefiran-WPI-MMT nanocomposites: kefiran-WPI (a), kefiran-WPI-1%MMT (b), kefiran-WPI-3%MMT (c), and kefiran-WPI-5%MMT (d) Fig. 4 SEM micrographs of cross-sections of kefiran-WPI-MMT nanocomposites: kefiran-WPI (a), kefiran-WPI-1%MMT (b), kefiran-WPI-3%MMT (c) and kefiran-WPI-5%MMT (d) 18