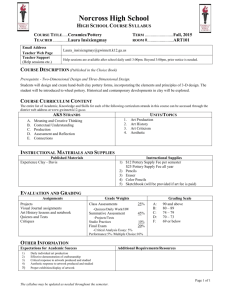

Pottery Vocab

advertisement

Pottery/Ceramic Terms Bisque - Glaze Firing – Bone Dry - Greenware - Clay - Grog – Clay body - Handbuilding - Coil - Impressed (design) -. Coiling - Incised (design) - Earthenware - Firing - Glaze - Kiln - Kiln Furniture Slab Construction Leather Hard Slip Maturing temperature Stoneware Pinch Throwing Plasticity Vitrification Potter Wall pocket Potters Wheel -. Wedging Raw - Pottery which has been fired once, without glaze. Completely air dried clay, ready to be bisque fired. The process of heating clay pottery in a kiln to bring the glaze or clay to a specific temperature and for a specific time. A thin coating that has been matured to the glassy state on a formed ceramic piece, or the material or mixture from which the coating is made. A mixture of water and powder from decomposed alumina, silica & feldspar. Clay is the potter's basic material. When clay is moist it is soft and plastic; when fired becomes permanently hard. The material used to form the body of a piece of pottery (earthenware, stoneware or porcelain) A piece of clay rolled like a rope, used in making pottery. A hand-building method of forming pottery by building up the walls with coils of ropelike rolls of clay. A low fired clay body. Glazed pottery is fired to a temperature of 1,830 - 2,010 degrees Fahrenheit. Available in red or also white. A firing cycle in a kiln to the temperature at which the glaze materials will melt to form a glasslike surface coating. The last firing of a pot when the glaze is applied. Unfired pottery. Ready to be bisque fired. Additives sometimes used in clay for texture Constructing pots from pre-made parts. The components might be molded, coiled or slab construction. Stamped into the leather-hard clay with a object or tool Pattern cut into the clay with a sharp tool. The oven/furnace in which pots are fired. Kilns can be fired by wood, coal, oil, gas or electricity. A device with either a manual (foot powered) or an electric rotating wheel head used to sit at and make pottery forms The various items made of refractory materials that are used in the kiln to support or protect the pots. unfired clay. A construction technique where flat sheets of clay are formed and jointed. Stage of the clay between plastic and bone dry. Clay is still damp enough to join it to other pieces using slip. For example, this is the stage were handles are applied to mugs. Fluid clay in a creamy texture used for joining harder pieces of clay together. The temperature at which a clay body reaches its optimum strength or a glaze is fully fused. Manipulate clay with you fingers in your palm to a hollow shape. This kind of pot is a popular beginners’ project. The quality of clay which allows it to be manipulated into different shapes without cracking or breaking. A person who makes pots or other ceramic art and wares. Pottery fired at high temperature. The clay vitrifies during firing and the surface will not absorb moisture. Stoneware can be left unglazed and still be usable for holding water, but it is more common to glaze the inside of the vessel. Stoneware is more durable than earthenware, and capable of resolving finer detail. The specific temperature for stoneware is between 2118 and 2205 The term used when referring to forming or shaping on a potter's wheel. The process of melting that clays and glazes go through as they are fired to maturity. In a fully matured clay body, the spaces between refractory particles are completely filled up with glass, fusing the particles together and making the clay body impervious to water. A vase, usually with a flat back, that has a hole or holes for fixing to a wall. The cutting of clay into wedges in the process of mixing and kneading it to an even consistency.

![[1.1] Prehistoric Origins Work Sheet](http://s3.studylib.net/store/data/006616577_1-747248a348beda0bf6c418ebdaed3459-300x300.png)