pubdoc_12_18295_228

advertisement

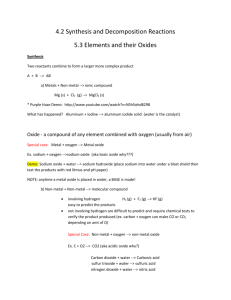

University of Babylon/College of Engineering Electrochemecal Engineering Dept./ 3rd Stage Corrosion engineering Dry corrosion (oxidation) When metal M ,is exposed at room or elevated temperature to an oxidizing gas e.g. oxygen, sulfur or halogen corrosion may occur in the absence of a liquid electrolyte .This is some time called “dry” corrosion in contrast to wet corrosion which occurs when a metal to liquid electrolyte or soil.In oxidation, an oxide layer or scale forms on the surface of metal , this phenomenon is called frequently termed scaling , tarnishing or dry corrosion Mechanism : Initial stages. A clean reactive metal surface exposed to oxygen follows the sequences • Adsorption of Oxygen • Formation of oxide nuclei • Growth of an continuous oxide film As in aqueous corrosion , the process of oxide layer formation is an electrochemical reaction may express M O2 MO2 Or in general xM 1 ( yO2 ) M x O y 2 Furthermore the above reacion consists of two reaction : This reaction take place at metal-scale interface M M 2 2e And the other reaction take place at metal-scale interface 1 O2 2e O 2 2 Figure (1) Schematic representation of processes that are involved in gaseous oxidation at a metal surface. For oxide layer increase in thickness , it is necessary that electrons be conducted to scale –gas interface , in addition metal ions must diffuse away from metal-scale interface and/ or oxygen ions must diffuse toward this same interface. Thus the oxide scale serve both as an electrolyte through which ions diffuse and as an electrical circuit for passage of electrons • The scale may protect metal from rapid oxidation when is acts as a barrier to ionic diffusion and /or electrical conduction ;most oxide s are highly electrically insulation Oxidation at elevated temperature A metal M, with oxygen or other gases at high temperature by initial adsorption of oxygen , chemical raection to form the surface oxide , oxide nucleation and lateral growth in continoues film that may protect the underlying metal The film may also thicken into a non protected scale with various defects including cavitation, microcracks and porosity. Oxidation in air by oxygen proceeds according to a reaction such as M O2 MO2 More generally (1) 1 xM ( yO2 ) M x O y 2 (2) A metal, M also can be oxidized similarly by either water vapor or carbon dioxide according to: xM yH 2 O M x O y yH 2 (3) xM yCO2 M x O y yCO (4) The MxOy oxide as formed on the metal surface , becomes a barrier between the substrate metal and the oxidizing environment.the chemical and physical properties of the oxide film are of paramount importance in determining oxidation rate and life of equipment exposed to high temperature oxidizing environments. Thermodynamics of oxidation ∆G◦ must be negative in order for reaction to proceed spontonously from left to right as wirren G H TS (5) When plot ∆G◦ versus temperature produce a straight line with changing slope when phases form (i.e., at melting or boiling temperatures) to get Ellingham diagram figure (2). For reaction metal M with oxygen a departure from standard conditions M O 2/ y gives: GO 2 / MO G O 2 / MO RT ln x y M 2 x / y O2 (6) GO 2 / MO RT ln pO2 , because activities of pure solids is unity Consider copper oxidation at 900 ◦C , extending a line from O on thr left scale through free energy line at 900 ◦C for copper to the scale marked pO2,CuO (blue line in the figure (2)) and this lead he value for pO2,CuO equal 108 atm , and ∆G = - 190 kJ/ mole , that mean any oxygen partial pressure above 10-8 atm will oxidize pure copper , any below it will reduce pure copper oxide to pure copper at 900 ◦C. Similar predictions can be made for atmospheres from mixture of water vapor and hydrogen, and carbon monoxide and dioxide ,again using the example of copper , extending a line from point H on left scale through freeenergy line of copper at 900 ◦C to scale H2/H2O ratio shows an equilibrum ratio of hydrogen to water vapor of 10-4 for a higher ratio cuprous oxide is reduced to pure copper;below it copper is oxidized , and same to get CO/CO2 ratio by use point C Figure (2) Ellingham tandard energy change diagram Oxide properties The oxidation rate of any alloy will be minimized if the oxide film has a combination of favorable properties which include: 1. The films should have good adherence , to prevent flaking and spalling. 2. The melting point for oxide should be high. 3. The oxide should have low vapor pressure to resist evaporation. 4. The oxide film and metal should have close to the same thermal expansion coefficients. 5. The film should have low electrical conductivity and low diffusion coefficients for metal ions and oxygen . 6. The film should have high temperature plasticity to accommodate differences in specific volumes of oxide and parent metal. Kinetics of corrosion in gases Application of metals and alloys in high-temperature environments is of technological importance since the rate of oxide layer formation, mechanism, and degree of protectiveness are the subject matter to be evaluated. Consider the model of oxide formation shown in below Figure in which a metal is exposed to an oxygen-rich environment at high temperatures . The model in Figure predicts that -The initial rate of oxide formation is determined by the reactions at the metal/oxygen interface . Thus , MxOy forms as a thin layer. - Once the thin layer is formed , it serves as a barrier separating or inslating the metal substrate .The subsequent oxidation steps are controlled by the diffusion of species M+2 and O-2 through layer If O -2 anions diffuse faster then M +2 cations ,the diffusion molar flux is J O-2 > J M+2 , then an oxide inner layer forms as shown in above figure (a) as oxide growth proceeds , the volume of oxide is VMxOy > VM causing a high stress concentration and consequentlythe oxide layer may rupture .Titanium falls into this category due to J O-2 > J +2 Ti . If M +2 cations diffuse faster than O -2 anions , then J M+2 > J O-2 and an outer oxide layer forms and proceeds through the concentartion gradient as shown in figure (b) .In this situation the stress concentration is reduced or relived .Thus , the oxide layer adheres to metal surface and protects the metal from further oxidation .Nickel falls into the category scince J Ni+2 > J O-2 Pilling-Bedworth ratio Metal oxide scales can be defined as protective and non protective using classical Pilling-Bedworth law as the ratio given by PB M M W ,O Vo VM x O M W .M Where : V◦ =volume of oxide scale (cm3) VM = volume of solid metal (cm3) ρ M ,ρ ◦= density of metal and metal oxide respectively ( g / cm3) M wM, Mwo= metal and metal oxide molecular weight respectively (g / mol ) x = is coefficient of metal species in equation (2) , in case of divalent metals the equation becomes: PB M M W ,O O M W .M The PB ratio is used to characterize several oxidation conditions thus ♦ If PB < 1 or PB > 2, the oxide scale is nonprotective (NP) and noncontinuous due to insufficient volume to cover the metal surface uniformly. Thus, weight gain is usually linear. ♦ If 1≤ PB ≤ 2 the oxide scale is protective (P), adherent and strong due to compressive stress, refractory due to high melting temperature, low electrical conductor, and nonporous. Because of these factors, diffusion proceeds in the solid state at low rates. Some oxides may not develop compressive stresses, invalidating PB law . ♦ If PB = 1, then the oxide scale is ideally protective Table 1 lists several metal / oxide PB ratios and quality In general , thermal degrdation of metals and alloys , and oxides scales is a is a major concern in practical applications such as furnce parts , heaters tubes and like .Degradation at high temperatures may occur isothermally or cyclically under operating conditions. Therefore, metallic parts must be protected using a lesser aggressive environments if possible; otherwise, applying a protective thin film prior to high temperature applications can be beneficial. on the isothermal and cyclic-oxidation behavior of austenitic stainless steel, such as AISI 316, 321, and 304, in dry air. Oxidation rate One of the primary concerns relative to metal oxidation is the rate at which the reaction progresses. Inasmuch as the oxide scale reaction product normally remains on the surface, the rate of reaction may be determined by measuring the weight gain per unit area as a function of time. When the oxide that forms is nonporous and adheres to the metal surface, the rate of layer growth is controlled by ionic diffusion. A parabolic relationship exists between the weight gain per unit area W and the time t as follows: W 2 K1t K 2 where K1 and K2 are time-independent constants at a given temperature. This weight gain–time behavior is plotted schematically in the below Figure. The oxidation of iron, copper, and cobalt follows this rate expression. In the oxidation of metals for which the scale is porous or flakes off (i.e., for P–B ratios less than about 1 or greater than about 2), the oxidation rate expression is linear; that is, W K 3t where K3 is a constant. Under these circumstances oxygen is always available for reaction with an unprotected metal surface because the oxide does not act as a reaction barrier. Sodium, potassium, and tantalum oxidize according to this rate expression and, incidentally, have P–B ratios significantly different from unity (Table 1). Linear growth rate kinetics is also represented in the figure Still a third reaction rate law has been observed for very thin oxide layers (generally less than 100 nm) that form at relatively low temperatures. The dependence of weight gain on time is logarithmic and takes the form W K 4 log( K 5 t K 6 ) Again, the K’s are constants. This oxidation behavior, also shown in Figure has been observed for aluminum, iron, and copper at near-ambient temperatures. Figure (2) Oxidation film growth curves for linear, parabolic and logarithmic rate laws Lecturer Hameed Hussein