Enablers for Smart Manufacturing

advertisement

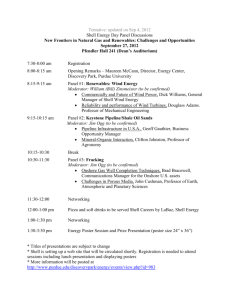

APMS 2013 International Conference Sustainable Production and Service Supply Chains September 9 -12, 2013 – State College, PA, USA Special Session Enablers for Smart Manufacturing Overview Smart manufacturing technology has the potential to create significant and measurable improvements in U.S. manufacturing competitiveness. New information and knowledge technologies can enable dynamic, demand-driven and sustainable industrial plants and supply chains. The purpose of the proposed panel session is to: (1) provide a venue discussion of current developments related to smart manufacturing, and; (2) elicit from the panel members and the session attendees priorities for new research directions and standardization efforts that could enable further advancements in this area. We feel this conference is a good fit for the panel because the development and deployment of smart manufacturing solutions are applicable to several of the stated conference topics including Digital Production and Manufacturing, ICT for Manufacturing, ICT for Supply Chain Management, and Inventory Control. Panel Makeup A five to six member panel will be constructed so that its members represent different industry viewpoints on the needs for enabling wider adoption of smart manufacturing approaches to manufacturing problems. To accomplish this, panel members will be drawn from different organizations interested in smart manufacturing such as major manufacturers, infrastructure/middleware solution providers, storage and computing service providers, standards developers, and SMEs. Each panel member will be asked to provide a one to two page position paper. Session Format The session’s duration will be two hours. A session moderator will be used to manage the session. The moderator will open the session with: (1) a welcome to the session for the audience and the panel; (2) a brief introduction to the topic of smart manufacturing, and; (3) a brief introduction for each panel member. The session moderator will call upon, in turn, each of the panel members to give a five to ten minute presentation about their views on smart manufacturing and what is needed to increase the deployment of smart manufacturing solutions. Each of the panel member’s talks should cover subjects such as: What is smart manufacturing? What work are they doing/intend to do in this area? What roadblocks/impediments keep them from deploying smart manufacturing solutions? What is “the way forward” for enabling greater adoption of smart manufacturing technologies? After the panel presentations are completed, the moderator will open up the session for questions from the session attendees. During periods of attendee “shyness”, the moderator will invite panel members to share views on how smart manufacturing relates to one of the conference’s theme topics such as Service Engineering or Modeling of Production Systems. When the allotted discussion period is over, the moderator will thank the panel members and the attendees for their participation and close the session. The organizers are open to any modifications to the format suggested by the conference committee. Organizers: Name: Affiliation: e-mail: Name: Affiliation: e-mail: Name: Affiliation: e-mail: Simon Frechette Program Manager Systems Integration for Manufacturing and Construction Applications (SIMCA) Program National Institute of Standards and Technology Gaithersburg, MD 20899 simon.frechette@nist.gov Frank Riddick (lead organizer) Project Leader Smart Factory Architecture (SFA) Project of the SIMCA program National Institute of Standards and Technology Gaithersburg, MD 20899 frank.riddick@nist.gov Evan Wallace Co-Project Leader Smart Factory Architecture (SFA) Project of the SIMCA program National Institute of Standards and Technology Gaithersburg, MD 20899 evan.wallace@nist.gov Example Session Program The table below is an example of the session program and the kinds of panel members that we anticipate will accept invitations to participate. Session Activity Introduction Panel Presentation Panel Presentation Panel Presentation Panel Presentation Panel Presentation Discussion Wrap-up Panel Member & Affiliation Moderator Jim Wetzel, Technical Director, General Mills Stephen Biller, Chief Manufacturing Scientist, General Electric Jim Davis, Smart Manufacturing Leadership Coalition (SMLC) Viewpoint on Smart Manufacturing Process and batch manufacturing Batch and discrete manufacturing 10 Smart manufacturing research and infrastructure development Cloud infrastructure 10 Brian Schott, CTO, Nimbus Services John Wen, Small and medium Director, sized manufacturing Center for Automation enterprises Technologies and Systems (CATS) Rensselaer Polytechnic Institute Moderator Moderator Total session time is approximately two hours. Duration (minutes) 10-15 10 10 10 50 5