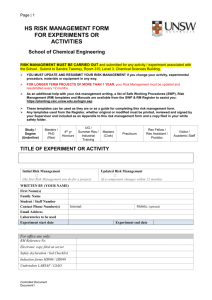

CHE_HSD_0026_HSD_0017 RISK MANAGEMENT

Page | 1

CHE_HSD_0026_HSD_0017

RISK MANAGEMENT

FOR EXPERIMENTS OR ACTIVITIES

School of Chemical Engineering

RISK MANAGEMENT MUST BE CARRIED OUT and submitted for any activity / experiment associated with the School. Submit to School Office, Room 310, Level 3, Chemical Sciences Building.

YOU MUST UPDATE AND RESUBMIT YOUR RISK MANAGEMENT if you change your activity, experimental procedure, materials or equipment in any way.

As an additional help with your risk management writing, there are a number of comprehensive Safe

Working Procedures (SWP), Risk Management (RM) documents and Manuals available from the SWP & RM

Register: https://plantreg.ceic.unsw.edu.au/login.asp

These documents can be used as they are or as a guide for completing this risk management form.

Please reference these in Section 9 of the Safe Work Procedure in this document.

Masters / 4 th yr Res Fellow /

PhD

Masters (C/wk)

Course Code

UG /

Summer Res

Visitor /

Academic Staff

(Res)

Honours

Course Code

Practicum Res Assistant /

Postdoc

WRITTEN BY (YOUR NAME)

Family Name

First Name(s)

Student / Staff Number

Contact Phone Number(s) Internal:

Email Address

Mobile: (optional)

TITLE OF EXPERIMENT OR ACTIVITY

Initial RM

Approval Date.

Version no. v1

Laboratories to be used

Updated RM (If a component changes after the initial approval ) v2 v3 v4

Experiment start date

Experiment end date

(no longer than 12 months)

Pay special note to the colour coding

YELLOW

BLUE

GREEN

GREY

Useful information and links to the University Health and Safety Website to be completed by the person undertaking the experiment / activity

To be completed by Supervisor

Office use only

Controlled Document документ1

Page | 2

CHE_HSD0026_HSD0017

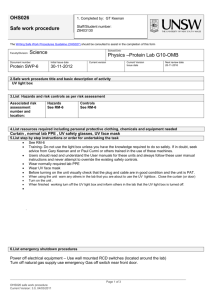

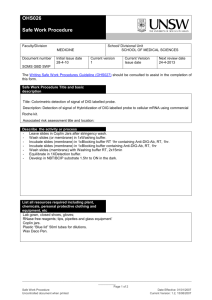

1 . Completed by ___________________

Safe work procedure

Staff/Student number _____________

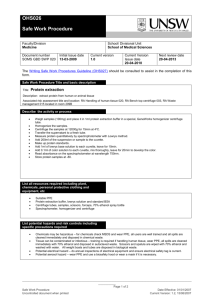

The Safe Work Procedures Guideline (HS027) should be consulted to assist in the completion of this form http://www.ohs.unsw.edu.au/hs_procedures_forms/guidelines/HS027_Safe_work_procedures_guideline.pdf

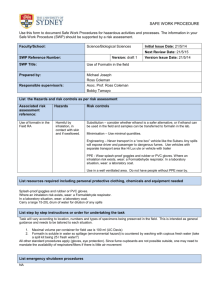

Faculty/Division:

ENGINEERING

School/Unit:

SCHOOL OF CHEMICAL ENGINEERING

Document number

(put student/ author’s z id)

Initial RM approval date Version no. Updated RM approval date.(must be the same as section 11)

Next Review date (1 yr after initial approval)

2.Safe work procedure title and basic description of activity

Title:

Description of activity:-

3.List hazards and risk controls as identified during risk management

Associated risk assessment number and location:

Hazards Controls

Complete these details on the HS Risk Management Form on page 4

4.List resources required including personal protective clothing, chemicals and equipment needed

Helper:

List chemicals you are using and refer to Safety Data Sheets (SDS) to determine level of personal protective clothing

(PPE) / equipment and laboratory resources you will require

Search SWP and RM Register for documents required for your activity / experiment (if available)

5.List step by step instructions or order for undertaking the task

6.List emergency shutdown procedures

7.List emergency procedures for how to deal with fires, spills or exposure to hazardous substances

Emergency response checklist (tick if applicable)

I have read and understood:

☐ UNSW Emergency procedure booklet

☐ All relevant chemical Safety Data Sheets

(SDS)

☐ Hazardous substance – handling and transportation (SWP_CHE_0051)

☐ Chemical spill control procedure

(SWP_CHE_0052)

☐ Biological Spill control procedure

List location of the nearest:

☐ Safety shower and eyewash:

Click here to enter text.

☐ First aid kit and first aid officer:

Click here to enter text.

☐ Spill control kit:

Click here to enter text.

☐ Fire extinguisher and fire blanket:

Click here to enter text.

☐ Breathing apparatus and trained personnel:

(SWP_CHE_0071)

8.List clean up and waste disposal requirements

Click here to enter text.

документ1

Page | 3

Waste disposal checklist (tick if applicable):

I have read and understood:

☐ UNSW Hazardous Waste Disposal Guideline

(HS321)

☐

Disposing of Empty Chemical Bottles

(SWP_CHE_0057)

List location of the nearest:

☐ Solid and liquid waste containers:

Click here to enter text.

☐

Broken glass bin and sharps bin:

Click here to enter text.

9.List legislation, codes of practice, manufacturers manual, industry standards etc used in the development of this SWP

Work Health and Safety Act 2011

Work Health and Safety Regulation 2011

Don’t forget to list SWP numbers / RM number / manual name used from the SWP&RM register https://plantreg.ceic.unsw.edu.au/login.asp

For example if you are handling chemicals and using a centrifuge refer to:

SWP_CHE_0051_Hazardous substances-handling and transportation procedures and SWP_CHE_0480_centrifuge

10a.List competency required – qualifications, certificates, licensing, training - e.g. course or instruction:

Helper:

Laboratory Safety Awareness Training and list other courses as required. Refer to the Health & Safety Training

Requirements document found in the white safety folder

10b. List competency of assessor

By signing below at Point 11 the Supervisor acknowledges that they have the necessary experience / qualifications outlined in this SWP / RM document.

Any specific competencies / qualifications can be listed.

11.Supervisory approval, and review

Supervisor:

Name: ____________________________________

Signature:

Date: _______________________

Responsibility for SWP review:

(Risk Management Author to review)

Date of review: _______________________

(experiment end date) документ1

Page | 4

CHE_HSD0026_HSD0017

HS Risk Management Form

For additional information refer to HS329 Risk Management Procedure http://www.ohs.unsw.edu.au/hs_procedures_forms/procedures/HS329_Risk_Management_Procedure.pdf

Faculty/Division: ENGINEERING School/Unit: SCHOOL OF CHEMICAL ENGINEERING

Document n umber (put student/author’s zid) Initial Issue date(initial approval date) Current version Updated RM approval date.(must be the same as section 11 in SWP and bottom of RM form)

Next review date(1 yr after initial approval)

Risk management name

Signature: Date:

Form completed by: _____________________ ID Number:

(Risk Management Author to sign here)

Responsible supervisor / authorising officer Name: Signature: Date:

Identify the activity and the location of the activity

Description of activity

Description of location

LIST LABORATORIES TO BE USED

Identify who may be at risk from the activity :

This may include fellow workers, visitors, contractors and the public. The types of people may affect the risk controls needed and the location may affect the number of people at risk

Persons at risk

How they were consulted on the risk

OTHER LAB USERS

ACCESS TO WHITE FOLDER

List legislation, standards, codes of practice, manufacturer’s guidance etc used to determine control measures necessary

Work Health and Safety Act 2011

Work Health and Safety Regulation 2011

REFER TO HSD0026_HSD0017 SAFE WORK PROCEDURE Section 9 документ1

Page | 5

Identify hazards and control the risks

1. An activity may be divided into tasks. For each task identify the hazards and associated risks. Also list the possible scenarios which could sooner or later cause harm

2. Determine controls necessary based on legislation, codes of practice, Australian standards, manufacturer’s instructions etc.

3. List existing risk controls and any additional controls that need to be implemented

4. Rate the risk once all controls are in place using the matrix in HS329 Risk Management Procedure

SHADED GREY AREAS

If you need to determine whether it’s reasonably practicable to implement a control, based on the risk complete the shaded grey columns

Feel free to resize the boxes to suit your situation/the amount of text you need to use

Task/

Scenario

Hazard

Associated harm Existing controls

Any additional controls required?

Risk Rating

C L R

Cost of controls

(in terms of time, effort, money)

Is this reasonably practicable

Y /N

документ1

Page | 6

List emergency procedures and controls

List emergency controls for how to deal with fires, spills or exposure to hazardous substances and/or emergency shutdown procedures

Note position of emergency brochure (read and understand), fire extinguishers, fire blankets, safety showers, first aid kits, spill control kit, fume cupboards, phone, safety folders and other emergency apparatus.

Implementation

Additional control measures needed: Resources required Responsible person Date of implementation

REVIEW (ACADEMIC SUPERVISOR)

Are all control measures in place?

Are controls eliminating or minimising the risk?

Are there any new problems with the risk?

Review by: (Academic Supervisor)

Review date: experiment end date

(No longer than 12 months)

Acknowledgement of Understanding

All persons performing these tasks must sign that they have read and understood the risk management (as described in HS329 Risk Management Procedure).

Note: for activities which are low risk or include a large group of people (e.g. open days, BBQ’s, student classes etc), only the persons undertaking the key activities need to sign below. For all others involved in such activities, the information can be covered by other methods including for example a safety briefing, induction, and/or safety information sheet (ensure the method of communicating this information is specified here)

Risk management name:

I have read and understand this Risk Management Form (Risk Management Author to sign here)

Name Signature Date

документ1