Engineering in fertilizer

advertisement

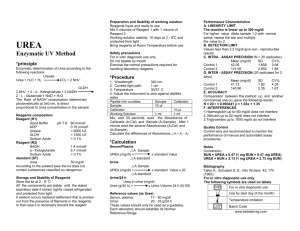

Plants are made up of four main elements, namely hydrogen (H₂), oxygen(O₂), carbon(C) and nitrogen (N₂). Carbon, hydrogen and oxygen are widely available as water and carbon dioxide and easily obtained from plants from soil and air. Although nitrogen makes up 75 percent of the atmosphere, it is in a form that unavailable to plants. Atmospheric nitrogen is nutritionally unavailable because nitrogen molecules are held together by strong triple bonds. In plants, nitrogen present in proteins, DNA and other main component such as chlorophyll. It shows that nitrogen is the most important fertilizer for the plant. To be nutritious, it must be in a fixed form or converted into some bioavailable form, through natural or man-made processes. Naturally, only some bacteria and their host plants can fix atmospheric nitrogen (N₂) by converting it into ammonia. Fertilizer is any material of natural or synthetic origin that is applied to soils or plant tissues which normally the leaves. This is to supply one or more plant nutrients essential to the growth of plants. It can be in the form of solid, powder or liquids. Fertilizer helps and enhance the growth of plants and this objective is met in two broad ways, the traditional one being addictive that provide nutrients and second, enhancing the effectiveness of the soil by modifying its water retention and aeration. Main micronutrients Nitrogen (N), phosphorus (P), potassium (K) together with secondary nutrients, calcium (Ca), magnesium (Mg), sulfur (S) and micronutrients copper (Cu), iron (Fe), manganese (Mn), molybdenum (Mo), zinc (Zn) and nickel (Ni) provided by the fertilizer are required by healthy plant life. A compound containing the elements is the basis of fertilizers. Fertilizer was used in the ancient time when the Egyptians, Romans, Babylonians and early Germans are using minerals and or manure to enhance the productivity of their farms. The use of wood ash as a field treatment became widespread. The method in fertilizing the plants using organic fertilizer such as animal matter, plant wastes from agriculture and wastes from meat processing, peat, manure, slurry guano and sewage sludge was then widely used around the world. Technological advances during world war two (WW2) accelerated post-war innovation in all aspects of agriculture, resulting in large advances in mechanization, fertilization and pesticides. The development of chemical synthesized fertilizer started in the 18th century and in the early decades of the 20th century, Carl Bosch and Fritz Haber developed a process which utilized molecular nitrogen (N₂) and methane (CH₄) gas in an economically sustainable synthesis of ammonia (NH₃). The process was named Haber process and the ammonia produced by this process has become the main raw material of the Ostwald process in 1902, developed by Wilhelm Ostwald. It is a chemical process for the production of nitric acid (HNO₃), a mainstay of the modern chemical industry and provides the raw material for the most common type of fertilizer production. Classification of fertilizers is done in many ways. Fertilizer which provides single nutrient is called as “Straight fertilizers” while fertilizer with more nutrients is called as “Multinutrient fertilizer”. The most common fertilizer used nowadays in agriculture is urea. Urea or carbamide is an organic compound with the chemical formula CO (NH2) 2. The molecule has two —NH2 groups joined by a carbonyl (C=O) functional group. Urea serves an important role in the metabolism of nitrogen-containing compounds by animals and is the main nitrogen-containing substance in the urine of mammals. It is a colorless, odorless solid, highly soluble in water and practically non-toxic. Dissolved in water, it is neither acidic nor alkaline. The body uses it in many processes, the most notable one being nitrogen excretion. Urea is widely used in fertilizers as a convenient source of nitrogen. The advantages of urea fertilizer are as follows; urea can be applied to soil as a solid or solution or to certain crops as a foliar spray; urea usage involves little or no fire or explosion hazard; urea's high analysis, 46% N, helps reduce handling, storage and transportation costs over other dry N forms; urea manufacture releases few pollutants to the environment; urea, when properly applied, results in crop yield increases equal to other forms of nitrogen. Urea is also an important raw material for the chemical industry. It was discovered by a German, Friedrich Wöhler in 1828 that urea can be produced from inorganic starting materials and was an important conceptual milestone in chemistry, as it showed for the first time that a substance previously known only as a byproduct of life could be synthesized in the laboratory. Friedrich Wöhler’s first artificial aura was obtained by treating silver cyanate with ammonium chloride. (AgNCO + NH₄Cl → (NH₂)₂CO + AgCl) It was the first time an organic compound was artificially synthesized from inorganic starting materials, without the involvement of living organisms. Nowadays, urea is produced on an industrial scale and used in many purposes, mainly agriculture, chemical industry, explosive, automobile systems, niche, laboratory, medical and analysis. The basic process of artificial urea production was developed in 1922 and was named after its discoverers, Bosch-Meiser. In industry, urea is produced from synthetic ammonia and carbon dioxide. The process starts with ammonia production plant, where ammonia is produced from the raw material, natural gas. The process is based on the Haber process, also called the Haber-Bosch process. It is the industrial implementation of the reaction of nitrogen gas and hydrogen gas and the main industrial procedure to produce ammonia. N₂ + 3H₂ → 2NH₃ In ammonia plant, ammonia production consists of steam reforming, shift conversion, carbon dioxide removal, methanation, synthesis and refrigeration. Hydrogen source is taken from methane and enriched by steam reforming, where amount of medium pressure steam is mixed with medium pressure process gas and flows through a series of catalyst and heated in a furnace. Carbon monoxide is converted into carbon dioxide over catalyst reaction in CO conversion and carbon dioxide later removed from the process gas in the CO₂ removal unit. The carbon dioxide is compressed and purified for urea production in urea plant. Passing the methanator unit, the hydrogen gas is ready to be fed into the synthesis unit. The source of nitrogen is taken from atmospheric air. Once compressed by a compressor, it is called process air and fed into the secondary reformer to aid the combustion through auto ignition. The oxygen in the compressed process air is fully utilized, leaving nitrogen in the process gas and flows to the downstream unit. In synthesis unit, nitrogen gas and hydrogen gas is compressed into a high pressure gas and later introduced into ammonia reactor, to produce ammonia with the aid of a catalyst. The ammonia gas product is again compressed and refrigerated in refrigeration unit, before the liquid ammonia is supplied to urea plant for urea production. Urea is produced commercially by the dehydration of ammonium carbomate (NH₂COONH₄) at elevated temperature and pressure. Ammonium carbonate is obtained by direct reaction of ammonia with carbon dioxide. These reactions are normally carried out simultaneously in a high pressure reactor. In urea plant process, urea is formed by reacting pressurized ammonia and carbon dioxide in urea reactor. This first form the intermediate, ammonium carbomate, which then breaks down into urea and water. Due to the reaction is relatively slow and incomplete, unreacted feedstocks are removed from the reaction products after the reaction of carbon dioxide stripping. The product has then undergone low pressure recirculation, followed by evaporation process. After the evaporation process, the product enters the granulation unit to shape the urea as granules. Urea is mainly used as fertilizer urea and normally marketed in solid form. In the earlier days, urea is produced as prills. The advantage of prills is that, they can be produced more cheaply than granules and the technique was firmly established in industrial practice long before satisfactory urea granulation was commercialized. However, the inferiority of urea prills to urea granules came into the picture when prills has limited size of particles that can be produced with the desired degree of sphericity, low crushing and impact strength, the performance of prills during bulk storage, handling and use. For fertilizer use, granules are preferred over prills because of their narrower particle size distribution, which is an advantage of mechanical application. For many years, high-quality compound fertilizers containing nitrogen co-granulated with other components such as phosphates have been produced routinely since the beginnings of the modern fertilizer industry, but on account of the low melting point and hygroscopic nature of urea it took courage to apply the same kind of technology to granulate urea on its own. But at the end of the 1970s, three companies, namely Nederlandse Stikstof Maatschappii, Toyo Engineering Corporation and Stamicarbon began to develop fluidizedbed granulation. Today, urea fertilizer is commonly found and marketed as urea granular. In agriculture, more than 90 percent of world urea production is destined for use as nitrogen release fertilizer. It has the highest nitrogen content of all solid nitrogenous fertilizers in common use. Therefore, it has the lowest transportation costs per unit of nitrogen nutrient. It makes urea fertilizer in granules a popular choice of countries around the globe. Based on a report by IFA Global Fertilizers and Raw Materials Supply and Supply/Demand Balances 2013 – 2017, for the year 2013, estimated 277,486,000 metric nutrient tones per year is produced in the world, with estimated 173,184,000 metric nutrient tones goes to nitrogen based and the statistic is expected to increase in the year 2014. Beside its valuable function in agriculture and specifically farming, urea fertilizer also may pose effects and threats to the environment. This comes from both upstream process, where the urea fertilizer is produced and at the downstream, where the urea fertilizer is used. Urea fertilizer is basically a naturally occurring product. It is not toxic, not radioactive and not harmful to the environment. Major environmental impacts normally come from ammonia/urea production plant liquid discharge, waste water system and emission from the stack. Although most of the ammonia/urea production complex runs the state-of-the art system, some unavoidable incidents does exists. Natural gas is the raw material to produce ammonia and carbon dioxide. Not all of the components are fully utilized in the process and the excess gas is vented to flare stack and burnt while furnace operations produce flue gas. Continuous process of both produces carbon monoxide and other greenhouse gases which affecting global temperature and ozone depletion. In the other hands, water treatment is crucial. Excess ammonia and urea in waste water contributes to excess Chemical Oxygen Demand (COD). At the downstream the environmental impact may be caused by nature, management system, human error and the urea fertilizer itself. In countries where heavy rains pose danger of flood, agricultural run-off is a major contributor to the eutrophication of fresh water bodies. For example, in the US, about half of all the lakes are eutrophic. The nitrogen-rich compounds found in fertilizer runoff are the primary cause of serious oxygen depletion in many parts of oceans, especially in coastal zones, lakes and rivers. Nitrogen-containing fertilizers can cause soil acidification when added. This may lead to decreases in nutrient availability which may be offset by liming. High levels of fertilizer may cause the breakdown of the symbiotic relationships between plant roots and mycorrhizal fungi. The biggest issue facing the use of chemical fertilizers is groundwater contamination. Nitrogen fertilizers break down into nitrates and travel easily through the soil. Because it is water-soluble and can remain in groundwater for decades, the addition of more nitrogen over the years has an accumulative effect. The NPK number for urea fertilizer is 46-0-0 which means, urea fertilizer is basically 45 percent of ammonia and the rest is inert. Excess application will reverse the benefits of urea fertilizer. In addition to their providing the nutrition of plants, excess fertilizers can be poisonous to the same plant. The excess application also contributes to increased accumulation of nitrates in the soil. An anonymous reports describes urea fertilizer is causing rapid growth pushes plants to grow too fast, promotes stress to plants, destroying soil organisms, increasing pest activities, increasing disease activities, urea breakdown into various compounds some of which can inhibit plant growth, decreasing plant production, decreasing nutritional values of plants to humans while increases nutritional value to pests and the carbon in urea based fertilizers is chemically converted to CO₂ and lost to the atmosphere. In general, the said implications seem to be caused by urea fertilizer itself. However, in most cases and situations, it is more related to humans, such as excess application, awareness and knowledge limitation. Some report claims that urea has adverse effects on seed germination, seedling growth, and early plant growth in soil. Because there is evidence that these adverse effects are caused largely, if not entirely, by ammonia produced through hydrolysis of urea fertilizer by soil urease. Successful study and experiment has proved that urea fertilizer’s adverse effect urea fertilizer on seed germination, seedling growth, and early plant growth in soil could be eliminated or markedly reduced by amending the fertilizer with as little as 0.01% (wt/wt) of N-(n-butyl) thiophosphoric triamide. While in another report describes that increased agricultural productivity over the past 50-100 years has led to increase of atmospheric concentration of CO₂, CH₄, N₂O and H₂O. These gases, along with additional trace gas species are referred to as ‘greenhouse gases’ and maybe causing an increase in global temperature and ozone depletion (NASA 1988; Rowland 1989). As an example, methane emissions from crop fields such as rice paddy fields are increased by the application of ammonium-based fertilizers. In year 2014, the world population has reached 7.2 billion people. The statistic came together with high number of hunger and malnutrition. As reported by the World Food Program (WFP) in the year 2014, some 805 million people in the world do not have enough food to lead a healthy active life. That's about one in nine people on earth. What does the number show? It is not only a statistic, but also shows a sign of significant increase in the needs of food supply, industrial development and services by the population. More demand for food puts pressure on agriculture as the main source of foods. Ammonia/urea production plant will increase the production, hence release more greenhouse gases and more population will contribute to increasing numbers of vehicles on the roads. The rapidly increasing importance of urea fertilizer in world agriculture has stimulated research to find methods of reducing the problems associated with the use of this fertilizer. The environmental effects can be eliminated or minimize by changing processes and procedures. Issues related to human can be minimized by continuous broadcast of information, awareness, knowledge and training. It may ensure correct methods are in place when dealing with urea fertilizer. For many years, studies on how to produce a slow-release formula of urea fertilizer has been a continuous effort while some of it shows a success. These formulas contain larger molecules that are coated, helping them to break down slowly in the soil. A typical slow-release fertilizer releases nutrients over a period of 50 days in a year, reducing the chance of burning the plant or root system. Specially formulated inorganic fertilizers are those that are created for a specific type of plant. As of the year 1995, Slow- and controlled-release involve only 0.15% (562,000 tons) of the fertilizer market. This includes the currently used urea formaldehyde. It is used as a controlled release source of nitrogen fertilizer. Urea formaldehyde’s rate of decomposition into CO₂ and NH₃ is determined by the action of microbes found naturally in most soils. The activity of these microbes, and, therefore, the rate of nitrogen release, is temperature dependent. The other identified method is Isobutylidenediurea (IBDU). IBDU is a single compound with the formula (CH3)2CHCH(NHC(O)NH2)2 whereas the urea-formaldehydes consist of mixtures of the approximate formula (HOCH2NHC(O)NH)nCH2. Sulfurcoated urea or SCU is another example of slow-release fertilizer. In sulfur coated urea, nitrogen is released via water penetration through cracks and micropores in the coating. Once water penetrates through the coating, nitrogen release is rapid. The particles of fertilizer may in turn be sealed with wax to slow release further still, making microbial degradation necessary to permit water penetration. In another field of use, Urea solution, made with 32.5 percent high purity urea and 67.5 percent deionized water which is called as ‘Adblue’, is a method used to convert harmful NOx pollutants in exhaust gases from combustion from diesel, dual fuel, and lean burn natural gas engines into harmless nitrogen and steam. It therefore considerably reduces the emissions of nitrogen oxides that are major source of atmospheric pollution and that lead to smog in urban centers. It is true that urea fertilizer has both the good and the bad. With continuous study and effort, the disadvantages of urea fertilizer may be brought to the minimum level. As worldwide accepted, fertilizer generated from ammonia produced by the Haber process is estimated to be responsible for sustaining one-third of the Earth's population and through time, it will continue to serve its purpose.