Supporting Information Fabrication and characterization of TiO2 film

Supporting Information

1.

Fabrication and characterization of TiO

2

film

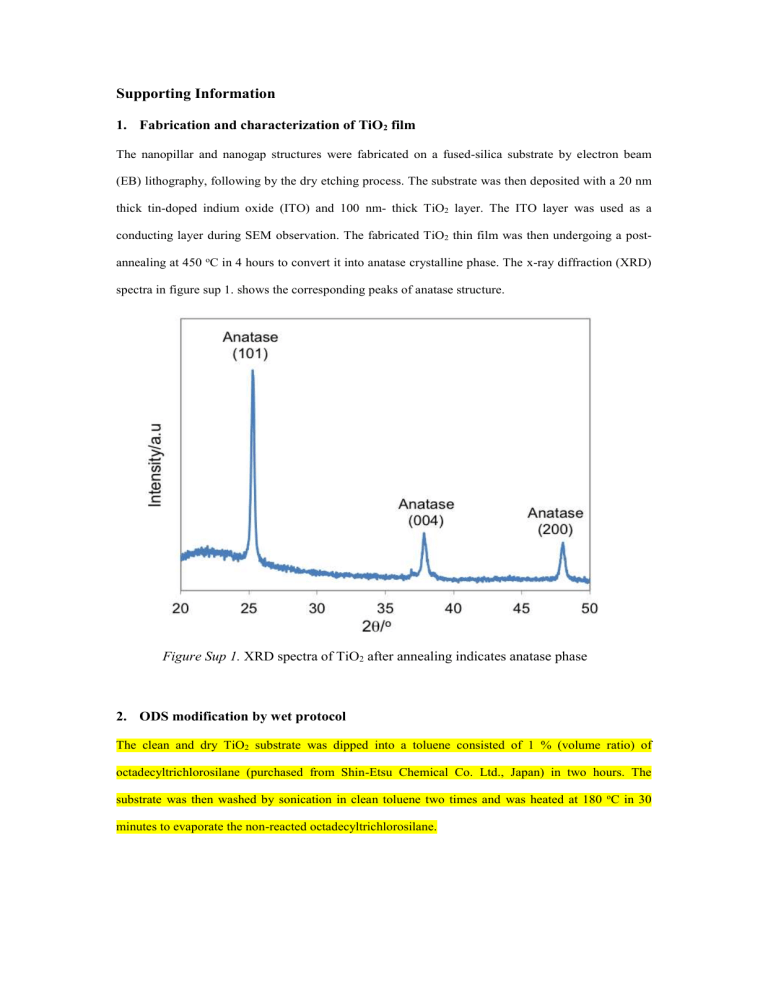

The nanopillar and nanogap structures were fabricated on a fused-silica substrate by electron beam

(EB) lithography, following by the dry etching process. The substrate was then deposited with a 20 nm thick tin-doped indium oxide (ITO) and 100 nm- thick TiO

2

layer. The ITO layer was used as a conducting layer during SEM observation. The fabricated TiO

2

thin film was then undergoing a postannealing at 450 o C in 4 hours to convert it into anatase crystalline phase. The x-ray diffraction (XRD) spectra in figure sup 1. shows the corresponding peaks of anatase structure.

Figure Sup 1.

XRD spectra of TiO

2

after annealing indicates anatase phase

2.

ODS modification by wet protocol

The clean and dry TiO

2

substrate was dipped into a toluene consisted of 1 % (volume ratio) of octadecyltrichlorosilane (purchased from Shin-Etsu Chemical Co. Ltd., Japan) in two hours. The substrate was then washed by sonication in clean toluene two times and was heated at 180 o C in 30 minutes to evaporate the non-reacted octadecyltrichlorosilane.

3.

TiO

2

-assisted photodeposition of Pt

After the ODS removal, the whole film was dipped into 0.5 mM aqueous solution (5% ethanol) of

H

2

PtCl

6

.6H

2

0 (purchased from Sigma Aldrich Japan K.K., Japan), and it is incubated in 30 minutes for the adsorption of PtCl

6

2 onto the hydrophilic TiO

2

. The substrate and the solution was then irradiated from the backside by a 365 nm Hg lamp for 30minutes. After that, the substrate was washed with water and dried for SEM observation.

4.

Energy dispersive x-ray (EDX) measurement

The energy dispersive x-ray (EDX) mapping was measured by the field emission scanning electron beam microscope (JSM-7500F, Jeol Ltd., Japan) at electron energy of 5.0 kV. At this energy, the penetration depth was large enough to overcome the ODS layer, and Ti and O elements could be detected. Figure sup. 2. shows a EDX mapping of O, Ti, and Pt elements for sample described in figure

2(b-1). The result indicates that Pt was only detected at the edges of nanostructures, while Ti and O were uniformly distributed on the whole surface except Pt-adsorbed area.

Figure Sup 2.

SEM image and EDX mapping of O, Ti, and Pt elements.

5.

Evaluation of modified feature size based on the pattern of deposited Pt

The definition and evaluation of pattern size were described in figure sup. 3. The pattern size was defined as the width of ODS removal pattern calculated from the edges of nanostructures. It was evaluated from the the Pt patterns in SEM images and the EDX mapping of Pt element, as explained in figure sup. 3. The pattern size was plotted against the irradiation intensity, as shown in figure 5(c). The error bars were the standard aviation. In the plot 5(c), for generate pattern sizes smaller than 200 nm, nanostructures of width 180 nm × gap 20 nm × height 50 nm were used, while for pattern sizes larger than 200 nm, nanostructures of width 900 nm

× gap 100 nm

× height 50 nm were used.

Figure Sup 3.

Definition and evaluation of pattern sizes based on the Pt patterns in SEM images