E-mail interview with Associate Professor Charlotta Löfström

advertisement

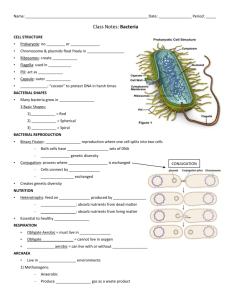

E-mail interview with Associate Professor Charlotta Löfström, National Food Institute, Technical University of Denmark. “New methods of detecting Salmonella in pork meat processing” 1. What are the traditional methods commonly used in characterising and detecting bacteria in pork meat processing? Traditionally, culture based methods have been used to detect and characterize bacteria in pork meat processing. These methods are based on growing the bacteria in different kinds of liquid media and/or on solid media (agar plates). Additives, such as different kinds of salt and antimicrobial substances, are used in combination with different temperatures and pH, to select for the bacteria of interest. Many times several different media are combined in sequence to enable selection and growth of specific bacteria. In the pork meat processing samples are taken on the carcass and meat products, but also in the production environment according to specific sampling plans laid out be national and international regulations and guidelines. Samples are then analyzed according to internationally validated standard methods that often are culture based, but sometimes alternative methods are also allowed, including DNA based methods. 2. How are they performing in the food factories? Culture based methods are often time consuming, for example it takes at least 2 days to see if a sample is negative for Salmonella. Moreover, culture methods are laborious and are on many occasions based on manual judgment of results. There are also many examples of both false positive and false negative results that are obtained by culture based methods, partly due to human error, but also due to bacterial strains that have atypical features such as colony morphology or ability to ferment sugars. Another shortcoming of culture based methods is that they only detect bacteria that are able to grow and multiply under the applied conditions. Sometimes this might lead to the failure of detecting bacteria that are damaged due to for example the cold conditions in the abattoirs, or in a very dry environment in other types of food factories. On the other hand, culture based methods produce an isolate that can be used for further characterizations, for example in tracing sources of outbreaks and/or contamination events in the production environment. 3. Could you share how the new methods of characterising and detecting illness-causing microorganisms will be useful for food factories? New methods based on, for example, the detection of nucleic acids such as DNA and RNA could help overcome some of the shortcomings seen with culture based methods. We have for example developed a method based on the polymerase chain reaction (PCR) that can be used to detect Salmonella in samples from pig carcasses in 14 h and from feed samples in 20 h. By using this, or other similar methods, food factories can save time due to the shortened time of analysis. This will lead to a more cost effective production because storage time will decrease and products can be shipped faster to the customer. For sensitive products such as fresh meat, this will also increase the shelf life of the product and give consumers access to products that are closer to the production date. Apart from savings in time, there are also other benefits with nucleic based methods. On many occasions decisions based on manual judgment are limited and the rate of false positive and false negative results minimized. 4. How soon can food factories test/use the methods you have created? Most of the methods that we have developed have been published in international peer-reviewed journals and are free and ready to use. However, when changing to a new method a validation test is needed to confirm that the method works for the sample type(s) analyzed and with the equipment and reagents that are used. There might also be regulations in place that hinders the use of alternative methods. 5. What is needed to ensure food safety in factories? There are many factors that contribute to ensure food safety in factories. One important factor is to use a risk analysis, such as HACCP, of the production to identify potentially weak points that might compromise food safety. Another important aspect is to establish a proper cleaning program to avoid cross contamination and establishment of a house flora of potentially pathogenic bacteria in food factories. 6. Concerning food safety and security, what do you recommend food factories to do to ensure safe processing environments? See question 5. Pictures (also supplied as separate files): Figure 1. Samples loaded on a PCR thermocycler in a method to test for foodborne pathogens. Figure 2. Cleaning of a slaughter house (Photo: Danish Crown). Figure 3. Sampling of pig carcasses for microbiological analyses (Photo: Danish Crown).