Professional Biography

advertisement

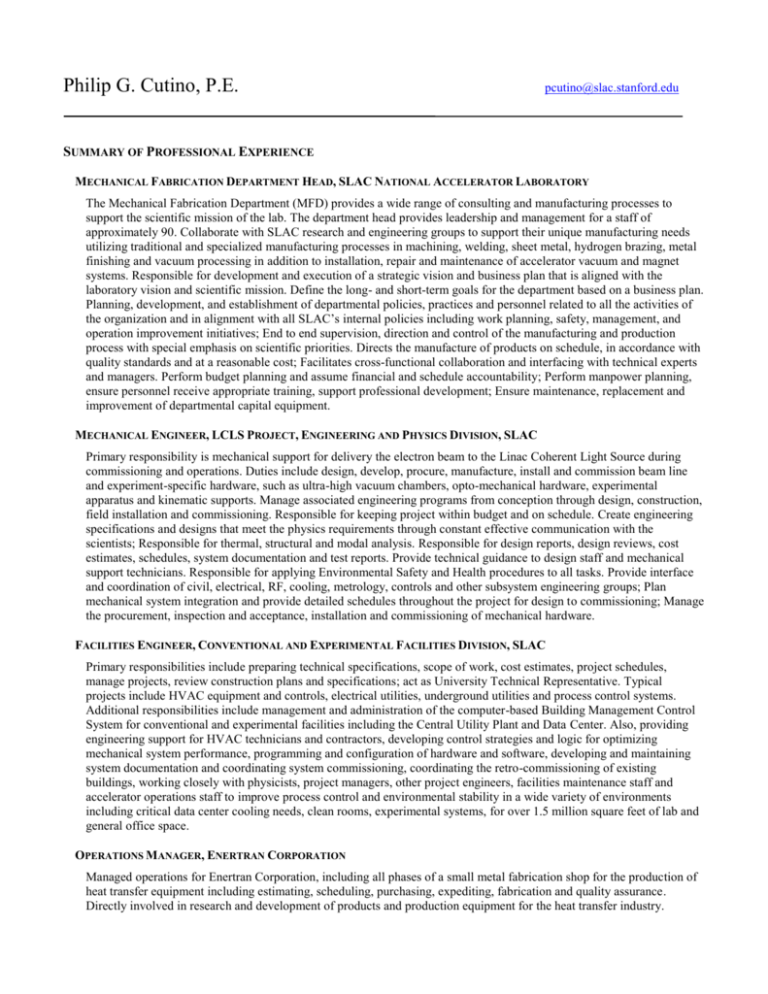

Philip G. Cutino, P.E. pcutino@slac.stanford.edu SUMMARY OF PROFESSIONAL EXPERIENCE MECHANICAL FABRICATION DEPARTMENT HEAD, SLAC NATIONAL ACCELERATOR LABORATORY The Mechanical Fabrication Department (MFD) provides a wide range of consulting and manufacturing processes to support the scientific mission of the lab. The department head provides leadership and management for a staff of approximately 90. Collaborate with SLAC research and engineering groups to support their unique manufacturing needs utilizing traditional and specialized manufacturing processes in machining, welding, sheet metal, hydrogen brazing, metal finishing and vacuum processing in addition to installation, repair and maintenance of accelerator vacuum and magnet systems. Responsible for development and execution of a strategic vision and business plan that is aligned with the laboratory vision and scientific mission. Define the long- and short-term goals for the department based on a business plan. Planning, development, and establishment of departmental policies, practices and personnel related to all the activities of the organization and in alignment with all SLAC’s internal policies including work planning, safety, management, and operation improvement initiatives; End to end supervision, direction and control of the manufacturing and production process with special emphasis on scientific priorities. Directs the manufacture of products on schedule, in accordance with quality standards and at a reasonable cost; Facilitates cross-functional collaboration and interfacing with technical experts and managers. Perform budget planning and assume financial and schedule accountability; Perform manpower planning, ensure personnel receive appropriate training, support professional development; Ensure maintenance, replacement and improvement of departmental capital equipment. MECHANICAL ENGINEER, LCLS PROJECT, ENGINEERING AND PHYSICS DIVISION, SLAC Primary responsibility is mechanical support for delivery the electron beam to the Linac Coherent Light Source during commissioning and operations. Duties include design, develop, procure, manufacture, install and commission beam line and experiment-specific hardware, such as ultra-high vacuum chambers, opto-mechanical hardware, experimental apparatus and kinematic supports. Manage associated engineering programs from conception through design, construction, field installation and commissioning. Responsible for keeping project within budget and on schedule. Create engineering specifications and designs that meet the physics requirements through constant effective communication with the scientists; Responsible for thermal, structural and modal analysis. Responsible for design reports, design reviews, cost estimates, schedules, system documentation and test reports. Provide technical guidance to design staff and mechanical support technicians. Responsible for applying Environmental Safety and Health procedures to all tasks. Provide interface and coordination of civil, electrical, RF, cooling, metrology, controls and other subsystem engineering groups; Plan mechanical system integration and provide detailed schedules throughout the project for design to commissioning; Manage the procurement, inspection and acceptance, installation and commissioning of mechanical hardware. FACILITIES ENGINEER, CONVENTIONAL AND EXPERIMENTAL FACILITIES DIVISION, SLAC Primary responsibilities include preparing technical specifications, scope of work, cost estimates, project schedules, manage projects, review construction plans and specifications; act as University Technical Representative. Typical projects include HVAC equipment and controls, electrical utilities, underground utilities and process control systems. Additional responsibilities include management and administration of the computer-based Building Management Control System for conventional and experimental facilities including the Central Utility Plant and Data Center. Also, providing engineering support for HVAC technicians and contractors, developing control strategies and logic for optimizing mechanical system performance, programming and configuration of hardware and software, developing and maintaining system documentation and coordinating system commissioning, coordinating the retro-commissioning of existing buildings, working closely with physicists, project managers, other project engineers, facilities maintenance staff and accelerator operations staff to improve process control and environmental stability in a wide variety of environments including critical data center cooling needs, clean rooms, experimental systems, for over 1.5 million square feet of lab and general office space. OPERATIONS MANAGER, ENERTRAN CORPORATION Managed operations for Enertran Corporation, including all phases of a small metal fabrication shop for the production of heat transfer equipment including estimating, scheduling, purchasing, expediting, fabrication and quality assurance. Directly involved in research and development of products and production equipment for the heat transfer industry. EDUCATION, AWARDS & TRAINING Registered Professional Mechanical Engineer in the State of California Bachelor of Science in Mechanical Engineering with Honors, University of California, Berkeley, December 2002. 3.62 GPA, Charles Parker Holt Memorial Scholar, Frank Jarrett Machine Design Award, California Alumni Association Leadership Scholar, Pi Tau Sigma Engineering Honor Society. Relevant Coursework: Design of Real Time Software for the Control of Mechanical Systems, Feedback Control & Dynamic Systems, Advanced Programming in MATLAB, Mechatronics Design Laboratory, also a research project implementing a real time temperature data acquisition system and HMI for a Computer Data Center using experimental networked wireless sensors. Specialized training includes: Basic Vacuum Practice, University Technical Representative, OSHA 510 Construction Safety, OSHA 3010 Excavation & Trenching, Electrical Safety for High and Low Voltage, Lock and Tag for Hazardous Energy, Asbestos Awareness, Hazardous Materials First Responder Awareness, Radiation Worker II, First Aid with CPR, Heavy Rescue Operations, Emergency Communications and others. SUMMARY OF TECHNICAL EXPERIENCE Over 20 years of hands-on technical experience in plant operations and maintenance, in both research and industrial environments, specializing in process control instrumentation and heat transfer equipment. Troubleshoot, install, configure, program and calibrate process control systems including: temperature, pressure, pH, and flow interlocks, indicators, recorders, programmable controllers, transducers, transmitters, control valves, motor controls and associated process control systems using microprocessor, pneumatic, electronic and mechanical controls. Innovate and fabricate custom control and data acquisition devices to solve many unique problems working from mechanical drawings, electrical schematics, logic diagrams, sketches or verbal instructions. Coordinate the work of instrument technicians and crafts workers to install the instrumentation, supervise and commission the field wiring of the SLAC Utility Distributed Control project. As Communications Group Coordinator for FEMA CA-TF3 Urban Search and Rescue Team, responsibilities included assuring the readiness of communication specialists and equipment, training the specialists to setup, configure and maintain hand held radios, repeaters, satellite and PBX telephone system, and computer network administration and representing the team and the district at state wide coordination meetings regarding communications issues.