Lecture Presentation

Philip G. Cutino, P.E.

Engineering 10 Presentation

April 19, 2012

Chabot College, Hayward CA

Today’s Agenda

SLAC National Accelerator Laboratory

Linac Coherent Light Source (LCLS)

My role at SLAC over the years

The Mechanical Fabrication Department

Mr. Phil Cutino • ENGR10 • Sp12

Stanford Linear Accelerator Center

Location: Menlo Park, CA

Type: Multi-program Laboratory

Contract Operator: Stanford University

Website: www.slac.stanford.edu

Physical Assets:

426 Acres

145 Buildings

1.8M GSF in Active Operational Buildings

Human Capital

Employees: 1,496 FTE as of 4/15/08

Users, Visiting Scientists and Grad Students: 3036 Head

Count

Mr. Phil Cutino • ENGR10 • Sp12

SLAC Mission

SLAC programs explore the ultimate structure and dynamics of matter and the properties of energy, space and time - at the smallest and largest scales, in the fastest processes and at the highest energies through robust scientific programs, excellent accelerator based user facilities and valuable partnerships .

Mr. Phil Cutino • ENGR10 • Sp12

Research at SLAC

Accelerator Physics

Astrophysics and Cosmology

Elementary Particle Physics

Materials and Nanoscience

Molecular Environmental Science

Structural Biology

Ultrafast Science http://www6.slac.stanford.edu/Research.aspx

Mr. Phil Cutino • ENGR10 • Sp12

LCLS

Linac 1003 meters

708 devices

Total Machine* : ~1750 meters of beam line 1242 Devices

Injector: 28 meters of beam line & 95 devices

LTU & Dump

408 meters

176 Devices

*Electron Beam Line Only

Does not include Photon Beam Lines

Mr. Phil Cutino • ENGR10 • Sp12

Linac Coherent Light Source

Ultrafast X-ray science

Directly observe the motions of atoms on ultrafast time scales

Investigate dynamics, bonding, heating and melting, at atomic and nanometer length scales

Create and observe extreme new conditions in atoms and materials

Imaging of nonperiodic molecules and nanostructured materials

World’s first X-ray free electron laser

Producing 100 femtosecond pulses of photons in the energy range 800-

8,000 eV

10^ 12 coherent X-ray photons/pulse

Potential for sub-femtosecond pulses

Lead nanoscale science revolution

Master control of energy-relevant complex systems

Lead the world in the investigation of dynamics of atomic transitions, chemical bonding, catalysis and heating

Mr. Phil Cutino • ENGR10 • Sp12

Links to More Information

http://www.slac.stanford.edu

http://lcls.slac.stanford.edu

http://www6.slac.stanford.edu/ExploringSLACScie nce.aspx

https://news.slac.stanford.edu/

Mr. Phil Cutino • ENGR10 • Sp12

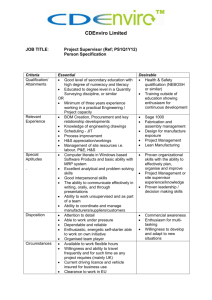

Atypical career path

Mechanical Engineer

Register Professional Engineer in CA

Returned to school late in life

Diverse background . . .

~25 years with the same employer

Four different jobs

Mr. Phil Cutino • ENGR10 • Sp12

My Roles at SLAC

Process Control Instrumentation

Technician

Facilities Engineer

Accelerator Engineer

Mechanical Fabrication Department Head

Mr. Phil Cutino • ENGR10 • Sp12

Mechanical Fabrication

Department

Phil Cutino

October 27, 2010

Mission and Vision

• Mission

– Provide specialized manufacturing and field support services necessary for the Lab to achieve it’s stated goals

– Provide collaborative and quick turn around manufacturing

– Provide services unique to the SLAC mission not available elsewhere

• Vision

– Partner with SLAC organizations to effectively deliver high quality manufacturing services in a safe and cost efficient manner supporting the scientific mission

Mechanical Fabrication Department

Page 12

Delivering SLAC’s Mission

• Broad capability on site for specialized manufacturing services

– High quality, consistency, capacity and unique accelerator research specific processes developed and delivered safely

• Technical know how developed over many years

– Highly trained & experienced staff available for changing needs of an experimental research user facility

• Quick turn around and collaborative manufacturing

– Metal Finishing

• Documented processes developed specifically for accelerator research needs

– Hydrogen Furnace Brazing

– Vacuum Processing and Precision Assembly

– Magnet fabrication, refurbishment and repair

– Machining

• Special capability such as ability to machine exotic & low-level radioactive materials

• Field work includes installation, installation coordination, accelerator mechanical and vacuum system maintenance and operations

Mechanical Fabrication Department

Page 13

Organization

• 85 Full time staff members

– 6 Engineers

– 12 Science & Engineering Associates

– 67 technicians and trades

• 9 supervisors

• 12 matrixed out

– Formal matrix agreements

• 9 are temporary employees

• Very experienced workforce

– 16% have 10 to 20 years of service

– 19% have 20 to 30 years of service

– 9% have more than 30 years of service

Mechanical Fabrication Department

Page 14

Organization continued

• Management (4)

– Mgmt., Admin., ES&H support

• Production Planning (6)

– Job inputs, Estimating

– Manufacturability Review

• Machine Maintenance (4)

• Field Operations (6)

• Vacuum Shop (21)

– Vacuum Processing

– Precision Assembly

• Braze Shop (7)

– Precision Assembly

• Machine Shop (12)

• Metal Finishing (8)

• Structural Fabrication Shop (7)

– Magnet Coil Shop

– Sheet Metal and Welding Shops

Mechanical Fabrication Department

Page 15

Core Competencies

• Broad range of technical know-how necessary to support the scientific mission

– Generally very high quality on site for ongoing and urgent operational needs as well as collaborative manufacturing

• Manufacturing & Field Support Services

– Seamless integration of production planning, machining, metal finishing, magnet fabrication, precision assembly, sheet metal forming, welding operations, quality assurance, vacuum processing with installation, maintenance and repair

Mechanical Fabrication Department

Page 16

Core Competencies continued

Machine Shop

Clean Machining for UHV

Quick Turnaround

Radioactive Materials

DFM & Prototype Parts

Mechanical Fabrication Department

Page 17

Core Competencies continued

Hydrogen Furnace Brazing

And

Heat Treating

Mechanical Fabrication Department

Page 18

Core Competencies continued

Metal Finishing

Plating and

Cleaning for UHV

Mechanical Fabrication Department

Page 19

Core Competencies continued

Mechanical and Vacuum

Processing and

Field Operations

Precision Assembly

Mechanical Fabrication Department

Page 20

Performing Work

• Customers have access to the manufacturing process

– Scope and technical changes are routinely accommodated

– Collaborative manufacturing is facilitated

– Problems are solved quickly

• Customer feedback is regularly provided

– Cost and schedule estimates are provided as part of the job input process

– Customers can check an online tool for real time updates

– Scope and technical changes are not re-estimated unless requested by the customer

• Regular planning meetings are held

– There is a standing weekly meeting for all field work

– Larger projects are coordinated in project specific meetings held weekly or as needed

Mechanical Fabrication Department

Page 21

Performing Work continued

• Quality assurance is integrated and documented on travelers.

– All machined parts are independently quality checked by MET unless the customer requests this step is to be skipped

– Vacuum processing reports are recorded in traveler

– Vacuum leak checking is provided in the shop on assemblies and in the field on systems

• Manufacturing process is seamlessly integrated

– Procurement of materials, machining, metal finishing, vacuum processing, precision assembly and installation can be procured from a single request

– In process storage of components and assemblies is provided

• Schedule updates are available to project managers

– Schedule reporting is provided to customers or to integrated schedules as requested by customers

• Change control is generally formal

Mechanical Fabrication Department

Page 22

Performing Work continued

Collaborative Manufacturing Example:

Wire Card for combination OTR / Wire Scanner

Developed for KEK by Doug McCormick (SLAC)

Resolution ~2 microns

Technical Challenge:

10 micron Tungsten Wire

Soldered to gold plated Macor substrate requiring high positional accuracy

Mechanical Fabrication Department

Page 23

Concluding Work

• Estimate vs. Actual reports are provided for all jobs.

– Actual costs are available online for future use in estimating.

– Historical and real time data is searchable by part number, customer name and job number.

– Performance reporting is facilitated using manufacturing software.

– Performance reports are published monthly.

• Scope changes are not typically re-estimated.

– Scope changes affect performance.

– Recently began tracking jobs with significant changes.

• All Redline drawings are routed back to MED for updating.

• An online feedback tool is available.

Mechanical Fabrication Department

Page 24

Questions and Answers

Mechanical Fabrication Department

Page 25