Exam 14/12 2012

advertisement

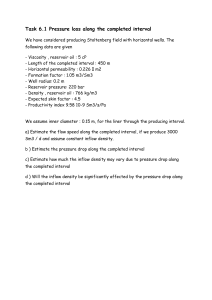

Exam 14/12 2012 Task 1. Gas well The following data are provided for the Lerchendahl field: Reservoir temperature Gas gravity Inner diameter production tubing Length production tubing Reservoir depth: Standard temperature Standard pressure Gas z factor at well conditions Gas viscosity at well conditions Interfacial tension water-gas Solubility water-in-gas at well conditions Density of produced water: Distribution parameters for two-phase flow 61 C 0.58 175 mm 2040 m 1850 m 15 C 1.01bar 0.86 0.0168 cP 60 dyn / cm 1.7 gram/Sm3 1010 kg/m3 Co = 1.2 Production test Gas rate Water rate Bottom well pressure Tubing head pressure (Sm3/d) (Sm3/d) (bar) (bar) 0 0 153.7 134.2 9.6 · 105 140 149.0 132.8 12.7 · 105 190 146.8 132.2 5 16.8 · 10 250 143.2 131.1 2 3 Inflow performance: pw pR 26500 qg 1410 qg (units: Pa, Sm /s) a) Estimate water flux fraction: w=Qw/(Qg+Qw), (a.k.a.: “no-slip holdup) at down hole well conditions b) Estimate gas production (Sm3 / d) so that superficial gas velocity at down hole conditions exceeds the sinking velocity of water droplets. (This is commonly considered the lower production to prevent accumulation of water in the well). c) Estimate water holdup in the well at the lower production limit estimated above. (If you have not found it, you may use: qg = 5 .105 Sm3 / d) d) The well produces at lower limit. Gas production is quickly increased to 15 .105 Sm3 / d. Estimate stable water production at the new gas rate and how long it will take till the water production reaches it’s stable level. (If you make approximations, discuss how these will affect the estimates, in relation to reality.) e) Estimate maximum water production, shortly after gas rate has been increased to : 15 .105 Sm3 / d. (Consider how potential approaches would affect the estimates.) Task 2 The Skalle field (illustrated below) has two productive zones. The table below lists properties Table Skalle Zone A Reservoir reference depth 2000 m Reference pressure 230 bar Layer height 30 m Horizontal permeability 200 md Vertical permeability 20 md Saturation pressure 35 bar Oil density, at reservoir conditions 700 kg/m3 Formation factor 1.5 m3/Sm3 Viscosity, at reservoir condionns 2.5 cP Reservoir temperature 60 C zone B 2000 m 235 bar 15 m 100 md 10 md 22 bar 750 kg/m3 1.6 m3/Sm3 1.5 cP 60 C The field will be produced by a horizontal well, illustrated below. Effective wellbore diameter is assumed: 200 millimeters. The well will be completed with a liner (pipe) with inner diameter: 120 millimeters. The annulus between zones A and B will be closed by a swell packer. Skin factor due to formation damage assumed: S = 2 a) Estimate the specific productivity index for each of the zones A and B. b) Show that if we complete both zones and neglect pressure drop along the well bore, the well pressure (pw), depending on specific productivity indices (j), interval length (L), reservoir pressure (pR) and total production (Qt), may be expressed as pw j A LA pRA jB LB pRB Qt j A LA jB LB c) Estimate the total production necessary to avoid cross flow between the zones. d) For rock-mechanical reasons, we cannot accept pressure drawdown above 20 bar (pR-pw <20bar). This applies to both zones. Estimate maximum production that fulfills this requirement. e) Consider the need for inflow control and give your recommendations Figure 1: Skalle reservoir and planned well Unit conversions 1 cp = 10-3 Pas 1 Darcy = 0.9869 10-12 m2 Physical constants, definitions Standard temperature :288 K 1 bar = 1 dyn/cm 105Pa = 10-3 N/m Standard pressure: 1.01 bar Formulae Fluid properties (SI, pressure in bar): Density, gas saturated oil: l o o g o Rs Bo Formation factor saturated oil,: Bo 0.9759 9.52 10 g o 4 Above saturation pressure: Gas density : 104 2.81 Rt 3.10 T 171 o 118 g 1102 p Bo Bob b p o pM g g zRT Bg g o po T z Bg g p T o zo Formation factor, gas: Gas solubility: 0.5 Rs 0.410 T 103 Rs 5.90 10 3 g 10 2.14 / o 10 0.00198 T 0.797 p 1.4 1.205 Viscosity due to dissolved gas: os a od , od : viscosity of gas free oil; 4.406 3.036 ; a b 0.515 Rs 17.809 Rs 26.7140.338 b Under saturated oil: o os 10 3 0.35 os1.6 0.55 os Single phase flow in reservoir and well 1 qo J Inflow characteristics: pw pR Flow in pipe: dp v d v g x dx Friction factor correlation: 1 2 f v dx 0 2 d f 0.16 Re 0.172 with: Re vd Horizontal wells, PI for isotropic permeability : 6 kh Long wells, pseudo steady : J x h h o Bo e 3 ln S Lw 2rw Lw 2kh J Short wells, steady: LD / h h ln o Bo ln S Lw / 4 Lw 2rw 6 kh Generally, pseudo steady: J D h h o Bo f a 3 ln S Lw 2rw 2 Lw 0.56 p p s 1.2 Geometry factor: fa Skin pressure loss: Lw L 2 1 Lw L L L 1 0 . 53 1.15 0.164 0.45 Lw L D D q B ps o o o S 2 k Lw Inclined wells Formulae as for horizontal, with: Lw= length of completed interval with skin due to inclination: S 0.57 (assuming well through formation height) Anisotropy Scaling rules for anisotropic permeability: kˆ k x k y Equivalent length of inclined well: Equivalent angle: tanˆ yˆ y k x k y y L̂w Lw 1 2 1 cos 2 Lw sin 1 tan Lw cos evt: cos ˆ Lw cos L̂w Inflow control Inflow density: qL jL pR pw x Specific productivity index: jL J Bo Lw Pressure drop reservoir – sand face: pR pw 1 qL jL Pressure drop along production liner, constant qL: pw 8 2 3 f 2 5 q L Lw 3 d 2 1 L Orifice based inflow control: pc c qL2 2 nc Ac Segregated flow Stationary crest: Stationary cone: qoL xe x o g w o qo r ho2 r he2 ln e o g w o r ho2 x he2 1 1 v w o g x w o g y tg w o w - w : stable interface inclination tg w yw x Flow in inclined layer: Transient rate after break through: qoL 2ko w o ghe2 K o t Two phase flow in pipes Rising/sinking velocity for small bubbles/drops: K = 1.53 for bubbles. K = 2.75-3.1 for droplets g d vo K 2 0.25 g vD 0.347 g D 1 l Rise velocity for Dumitrescu bubbles: Velocities: vg vsg yg vsg vl 1 yl vsl yl Drift flux relation: vg Co vl vo Usually: Co in the range of 1 - 1.4 Stationary liquid fraction: 1 yl 2 2 vsg v v Co sl 1 4Co sl vo vo vo v 1 vsg Co sl 1 2 vo vo Flux fraction: l vsl / vm Volume averaged density: TP g y g l yl Flow averaged density: m g g l l 2 1 dp TP g x dx g vsg dv g l vsl dvl cTP f o m vm dx 0 2 d v d fo : 1-phase friction factor, for 2-phase Reynolds number: Re m m m Pipe flow relation: Slip multiplier: m g yl 1 l 2 l 1 yl l 2 cTP m yl 1 yl Critical velocity : v* p TP cTP p l yl 1 yl vm vo yl vo yl 2 Co 1 yl yl 2 vm vo Co 2Co vo yl Co 1vo yl Co 1 yl yl 2 Superficial velocity, at given total velocity: vsl Kinematic wave velocity: Shock velocity: v f vk vsl yl vm vsl ,2 vsl ,1 yl ,2 yl ,1 General gas constant Acceleration of gravity :8314 Mole weight air 2 :9.81 … m/s : 28.97 kg/kmole