Estimate at downhole conditions

advertisement

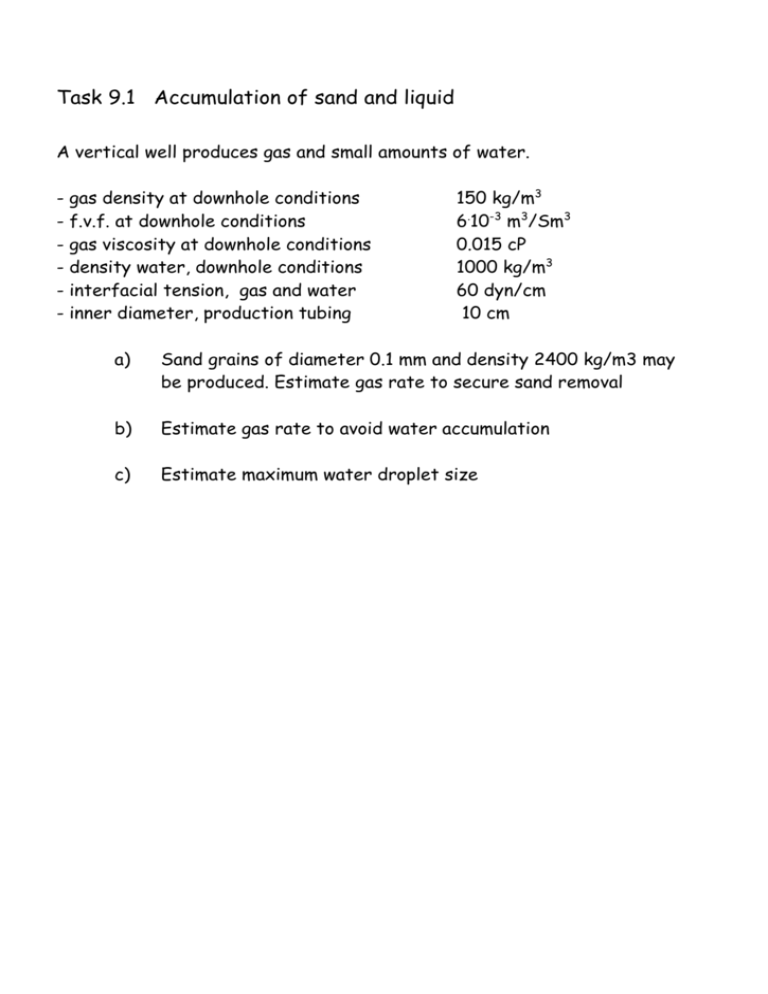

Task 9.1 Accumulation of sand and liquid A vertical well produces gas and small amounts of water. - gas density at downhole conditions - f.v.f. at downhole conditions - gas viscosity at downhole conditions - density water, downhole conditions - interfacial tension, gas and water - inner diameter, production tubing 150 kg/m3 6.10-3 m3/Sm3 0.015 cP 1000 kg/m3 60 dyn/cm 10 cm a) Sand grains of diameter 0.1 mm and density 2400 kg/m3 may be produced. Estimate gas rate to secure sand removal b) Estimate gas rate to avoid water accumulation c) Estimate maximum water droplet size Task 9.2 Droplets in flowing gas In Task 9.1 we found droplet velocity: 1.2 m / s According to the Turner criterion, the gas speed should exceed this. At gas velocity 1.2m / s, we may assume wall friction factor: f = 0.02 a) Check if flow turbulence will affect droplet sizes. b) Estimate the maximum droplet size Task 9.3: Two-phase flow in the production tubing The following data is given for an oil-well: - Oil production: - Gas content in reservoir oil: - Lift gas injection - Specific gas gravity: - Specific oil gravity: - tubing length - inclination 1194 Sm3/d 110 Sm3/ Sm3 2.5.105 Sm3/d 0.7 0.84 2010 m 22o At downhole conditions: - solubility gas: - formation volume factor, oil: - formation volume factor, gas: - temperature - pressure - viscosity, oil: - viscosity, gas: - inner diameter, production tubing - interfacial tension: - gas z-factor 210 Sm3/ Sm3 1.54 m3/ Sm3 4.52.10-3 m3/ Sm3 90 C 307 bar 0.5 cP 0.0012 cP 10 cm 10-3 N/m 0.95 Estimate at downhole conditions: a) b) c) d) e) Superficial velocity for liquid and gas. Flux fraction Flowregime. Pressure gradient at downhole conditions Tubing head pressure, by linear extrapolation Task 9.4: Two-phase flow and pressure loss From the previous exercise (9.3), we have estimated the following at downhole conditions: - superficial velocity, gas - superficial velocity, oil - gas density - oil density 0.875 m/s 2.71 m/s 189 kg/m3 662 kg/m3 Additional data: - viscosity, oil: - viscosity, gas: - inner diameter production tubing: - inclination: - production tubing length: - inflow pressure: - bubble distribution parameter: - rise velocity of bubbles: - friction factor correlation: Estimate: a) Liquid and gas fraction. b) Liquid and gas velocity. c) Pressure gradient. d) Wellhead pressure 0.5 cP 0.0012 cP 10 cm 22 o 2010 m 198 bar Co = 1.1 vo = 0.2 m/s fo = 0.16/Rem0.172