Exam i course - Institutt for petroleumsteknologi og anvendt geofysikk

advertisement

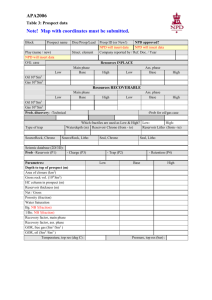

Institutt for petroleumsteknologi og anvendt geofysikk Exam i course: TPG 4245 Produksjonsbrønner Academic contact during examination: Harald Asheim Phone: 73 59 49 59 Examination date: 21. desember 2013 Examination time (from-to): 0900 - 1300 Permitted examination support material: C - 3 paper sheets A4, hand written or printed Language: English Number of pages: 5 Checked by: ____________________________ Date Signature ASSIGNMENT BASIS Approximate reservoir geometry is illustrated below Reservoir Data: Reservoir Temperature: Reservoir pressure: Depth: Gas gravity: Oil gravity: Gas / oil ratio: Saturation pressure: Oil formation volume factor: Horizontal permeability: Vertical permeability: Viscosity: 72 C 233 bar 2200 m 0.98 0.808 148 Sm3/Sm3 173 bar 1.49 m3/Sm3 100 mD 5 mD 5 cP Design criteria and assumptions: - Pressure loss reservoir-wellbore should not exceed 35 bar. - Well drilled with the bit diameter: 200 mm. - Production target: qo = 600 Sm3 / d - Average velocity along the completed interval at least: 1.5 m / s (to remove fines). - Friction factor, flow in pipes: f = 0.02. - Liner inner diameter: 50 mm along the completed interval, - Production Pipe inner diameter: 100 mm, length 3000 m, from the end the completed interval to the separator at surface. - Two-phase slip flow parameters: Co = 1.2, vo = 0 - Separator pressure: 30 bar. - Gas Formation Factor at separator pressure and temperature: Bg = 0.036 Task 1: Well Location, productivity a) Estimate productivity index for wellbore trajectory "a" indicated in the figure above ( completed interval: 500m along the shortest reservoir axis) b ) Estimate productivity index for wellbore trajectory "b" indicated in the figure above ( completed interval: 500m along the shortest reservoir axis) c ) Investigate to which degree inclined wellbore trajectory may affect the productivity index d) Investigate the need for inflow control to achieve constant inflow density along the completed interval. (In case you have not achieved a trustworthy estimate of the productivity index, J = 15 Sm3/d/bar may be used. ) e ) Examine the proposed well design and consider changes. Task 2 : Completion, production It has been decided to locate the well along the longest reservoir axis: Lw = 1000m. Specific productivity index to be used for design purposes: jL 5 1012 m3 / s / Pa / m . Constant inflow density assumed, achieved by orifice based ICD. a) Estimate tubing inlet pressure with production rate: qo = 600 Sm3 / d b ) Estimate tubing inlet pressure gradient c ) Where the production pipe will gas first begin to be released d ) Estimate the flow speed at the end of the production pipe (at Xmas tree ) , when the well produces naturally (without choking ) at rate: qo = 600 Sm3 / d e ) Consider gas lift versus downhole pumping for sustainable design rate beyond natural plateau period Unit conversions 1 cp = 1 Darcy = 10-3 Pas 0.9869 10-12 m2 1 bar = 105Pa 1 dyn/cm = 10-3 N/m Physical constants, definitions Standard temperature :288 K Standard pressure: 1.01 bar General gas constant :8314 Mole weight air : Acceleration of gravity :9.81 … m/s2 28.97 kg/kmole Formulae Fluid properties (SI, pressure in bar): Density, gas saturated oil: l o o g o Rs Bo g Formation factor saturated oil,: Bo 0.9759 9.52 10 o 4 0.5 Rs 0.410 T 103 1.2 104 2.81 Rt 3.10 T 171 o 118 g 1102 p Bo Bob b p o pM g g zRT Bg Above saturation pressure: Gas density : g o po T z Bg g p T o zo Formation factor, gas: Gas solubility: Rs 5.90 10 3 g 10 2.14 / o 10 0.00198 T 0.797 p 1.4 1.205 Single phase flow in reservoir and well 1 qo J Inflow characteristics: pw pR Flow in pipe: dp v d v g x dx Velocity: v Q d2 / 4 Friction factor correlation: f 0.16 Re 0.172 with: Re 1 2 f v dx 0 2 d vd Horizontal wells: Long wells, pseudo steady : J 6 kh xe h h 3 ln S Lw 2rw Lw 2kh Short wells, steady: J LD / h h ln o Bo ln S Lw / 4 Lw 2rw 6 kh Generally, pseudo steady: J D h h o Bo f a 3 ln S Lw 2rw 2 Lw o Bo Geometry factor: L fa w L 2 1 Lw L L L 1 0.53 1.15 0.164 0.45 Lw L D D ps Skin pressure loss: qo o Bo S 2 k Lw Scaling rules for anisotropic permeability: kˆ k x k y Inclined wells Geometric skin: Sb ln 2 0.69 yˆ y k x k y y L̂w Lw 1 2 1 cos 2 Equivalent length: Inflow control Inflow density: qL jL pR pw x Specific productivity index: j L J Bo Lw Pressure drop reservoir – sand face: pR pw 1 qL jL Pressure drop along production liner, constant qL: pw 8 2 3 f 2 5 qL Lw 3 d 2 1 L 2 Orifice based inflow control: pc c qL 2 nc Ac Two phase flow in pipes g d Rising/sinking velocity for small bubbles/drops: vo K 2 0.25 K = 1.53 for bubbles. K = 2.75-3.1 for droplets g vD 0.347 g D 1 l Rise velocity for Dumitrescu bubbles: Velocities: vg vsg yg vsg vl 1 yl vsl yl Drift flux relation: v g Co vl vo 2 vsg v v Liquid fraction: Co sl 1 4Co sl vo vo vo Flux fraction: l vsl / vm Volume averaged density: TP g y g l yl 1 yl 2 v 1 vsg Co sl 1 2 vo vo Flow averaged density: m g g l l 2 1 dp TP g x dx g vsg dvg l vsl dvl cTP f o m vm dx 0 2 d m vm d 2-phase Reynolds number: Re m Pipe flow relation: m