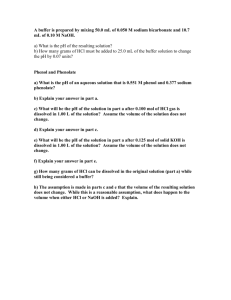

Table 1: Formulation of Tramadol hydrochloride immediate release

advertisement

FORMULATION AND EVALUATION OF IMMEDIATE RELEASE TABLETS OF TRAMADOL HCL USING DIFFERENT SUPERDISINTEGRANTS Mayur Inamdar*1, Pooja Abhang1 1 Oriental College of Pharmacy, Sector-2, Near Sanpada Railway station, Sanpada (E), Navi Mumbai-400705. Email: mayurinamdar7@gmail.com *Corresponding author: Mr. Mayur Ashok Inamdar Research Scholar Department of Pharmaceutics Oriental College of Pharmacy, Sector-2, Near Sanpada Railway station, Sanpada (E), Navi Mumbai-400705 Email: mayurinamdar7@gmail.com Telephone: 8108146663 ABSTRACT: The objective of this research was to formulate an immediate release tablet of Tramadol HCL for rapid action, by using a suitable diluents and super-disintegrants. Faster disintegration of the tablet administrated orally minimizes absorption time and improves its bioavailability in less time. Immediate Release tablet of analgesic drug is formulated by direct compression using super disintegrant croscarmellose sodium, sodium starch glycolate and Starcap 1500. Tramadol an opioid analgesic drug has been used as an add-on treatment in adults and children and has been proved to be efficient in managing relief from pain and including pain after surgery. The powder blend was evaluated for the pre-compression parameters such as bulk density, compressibility, angle of repose etc. The prepared batches of tablets were evaluated for hardness, weight variation, friability, drug content, disintegration time and invitro dissolution profile and found satisfactory. The drug release from immediate release tablets increased with increasing concentration of superdisintegrants and was found to be highest with formulations containing sodium starch glycolate with 10% concentration. KEYWORDS: Tramadol HCL, superdisintegrants, Sodium starch glycolate, Starcap 1500, Croscarmellose. INTRODUCTION The oral route of administration has so far received the maximum attention with respect to research on physiological and drug constraints as well as design and testing of products. (1) Oral ingestion has been the most convenient and commonly used route of drug administration because of its flexibility and dosage form design. (2) Tramadol hydrochloride is a centrally acting opioid analgesic structurally related to codeine and morphine used in the treatment of moderate to severe pain in diverse conditions. Combined with low dependence/abuse potential, it has proven to be of significant advantage over other agents, especially in the elderly. (3) Tramadol hydrochloride has been proved to be effective in both experimental and clinical pain without causing serious cardiovascular or respiratory side effects. (4) Tramadol hydrochloride is freely soluble in water. (5)The half-life of the drug is about 5.5 hours and the usual oral dosage regimen is 50 to 100 mg every 4 to 6 hours with a maximum dosage of 400 mg/day. Tramadol possesses weak agonist actions at the μ-opioid receptor, releases serotonin, and inhibits the reuptake of norepinephrine. The analgesic action of Tramadol has yet to be fully understood, but it is believed to work through modulation of serotonin and norepinephrine in addition to its mild agonism of the μ-opioid receptor. The contribution of non-opioid activity is demonstrated by the fact that the analgesic effect of Tramadol is not fully antagonised by the μ-opioid receptor antagonist. Tramadol is used in the treatment of moderate to severe pain. Also used in the treatment of sever to chronic pain when the treatment needed around the clock. It is the lightest and most compact than other dosage forms. It is bearing objective like rapid dispersion, patient convenience and compliance. The main aim of IR technology is to achieve improved bioavailability, rapid onset of action, chemical stability and patient convenience and compliance. (6, 7) MATERIALS AND METHOD Tramadol Hydrochloride, Microcrystalline cellulose (MCC) (Avicel PH 102) and Magnesium stearate were obtained as gift samples from Rubicon Research Pvt. Ltd. Starcap 1500 were obtained as gift sample from Colorcon Mumbai. Sodium starch glycolate (SSG) (Primojel) and Croscarmellose sodium (Primellose) were obtained as gift samples from Colorcon Asia Pvt Ltd (Mumbai). Double distilled water was used throughout the experiment. All other reagents were of analytical grade. ANALYTICAL METHOD VERIFICATION (8) To determine the λ max in UV Spectrophotometer (Shimadzu 1800) a standard stock solution of 100 µg/ml of Tramadol HCl was examined between 200 to 400 nm. The λ max was found to be 271 nm Specificity: The specificity was checked by dissolving 400 mg of placebo in 900 ml of 0.1 N HCl and sonicated for 30 minutes. The solution was then filtered using Whatmann Filter paper and the UV absorbance was taken at λ max of 271 nm. Linearity: Specific volume of aliquots were withdrawn from the standard stock solution into different volumetric flasks and diluted with 0.1 N HCl so as to prepare the solutions of 10, 20, 40, 60, 80 and 100 µg/ml. The absorbance of these solutions was taken at λ max of 271 nm using 0.1 N HCl as blank. FORMULATION OF IMMEDIATE RELEASE TABLET OF DRUG BY DISINTEGRANT ADDITION METHOD: Tramadol HCL Immediate release tablets were prepared by using direct compression method after incorporating different superdisintegrants such as, Crosscarmellose sodium (Ac-Di-Sol), Starcap 1500 and sodium starch glycolate in different concentrations. Microcrystalline cellulose (MCC) was used as directly compressible diluents. The super disintegrant were used to formulate the tablets. All the materials were passed through mesh no.60 prior to mixing. Tramadol, MCC, Sodium starch Glycolate (SSG), Crosscarmellose sodium and Starcap1500 were mixed using a glass mortar pestle. Nine formulations of Tramadol hydrochloride tablets were prepared and each formulation contained one of the three disintegrant in different concentration. Tablet weight was 200 mg; 8 mm punch was used for compression. PHARMACO TECHNICAL EVALUATION OF TRAMADOL HCL IMMEDIATE RELEASE TABLET: PRECOMPRESSION PARAMETERS: (9, 10, 11) 1. Bulk density (Bd) The term bulk density refers to a measure used to describe a packing of particles. The bulk density of powder was obtained by dividing the mass of a powder by the bulk volume in cm3 (V). The standard method (USP) was adopted for measurement of bulk density and following equation was used for calculation. M Bd = V Where, M = weight of samples in grams, V= bulk volume of powder in cm3. 2. Tapped density (Td) The tapped density or poured density attained after mechanically tapping a container containing the powder sample. The standard method described in USP was followed and tapped density was calculated using equation given below: 𝑀 Td == 𝑉 𝑝 Where, M = weight of samples in grams and Vp = final tapped volume of powder in cm3. 3. Carr’s index An indirect method of measuring powder flow from bulk densities was developed by Carr. A low Carr’s index implies a good initial packing arrangement, with less volume of voids. As the value of these indices increases, the flow of the powder decreases. In general, however, Carr’s index below 16% indicates good flowability while values above 35% indicate cohesiveness14. Carr’s index of each sample was calculated according to equation given below: 𝑇 −𝐵 CI =100 ( 𝑑𝑇 𝑑 ) 𝑑 4. Hausner’s ratio Hausner’s ratio measures the powder ability to settle and permit an assessment of the relative importance of interparticulate interactions. Hausner’s ratio is calculated as the ratio of bulk density to tapped density. The Hausner’s ratio less than 1.25 indicates good flow; the values between 1.25 to 1.5 assure that adding glidant will improve flow ability. HR= V0 Vf Where, V0: unsettled apparent volume, Vf: final tapped volume 5. Angle of Repose Angle of repose has been defined as the maximum angle possible between the surface of pile of powder and horizontal plane. The angle of repose was determined by the fixed height funnel method. The angle of repose was calculated by substituting the values of the base radius ‘r’ and pile height ‘h’ in the following equation: ℎ tan = 𝑟 ℎ Therefore; = tan –1 ( 𝑟 ) 6. Determination of flow rate Ten grams (10g) (w) of the powder were passed through dry glass funnel and allowed to flow through the funnel orifice. The time taken for the powder to flow through the orifice (t) was noted and the flow rate was computed as; 𝑤 𝑡 8. Percent compressibility (%C) It is an important measure that can be obtained from bulk density measurements. It is the simple test to evaluate the V0 and Vf of powder and the rate at which it packed down. The following formula was used to compute the percent compressibility. 100(V0 − Vf ) V0 Where, Vf = packed bulk density V0 = apparent bulk density POST COMPRESSION PARAMETERS: 1. Weight variation: Twenty tablets were selected randomly from each batch and weighed individually on electronic balance. The individual weight is then compared with the average weight for the weight variations. 2. Hardness: The hardness of the tablet was determined using Pfizer hardness tester. 3. Wetting time study: The experiment was designed to evaluate the water uptake rate by the tablet. 25 ml of water was placed in a Petri dish. The band of the filter paper, supported on the glass slide, was partially dipped in water. A tablet was placed on the surface of filter paper band. The uptake of water occurred from the lower surface of tablet. The time required for water to reach the centre of the upper surface of the tablet was noted. 4. Water absorption ratio: Test was done with the same procedure as that of wetting time. In this test, initial weight of the tablet was noted before placing it on the Petri dish. After complete wetting, the wet tablet was then weighed. Water absorption ratio, R was determined using equation, 𝑊 −𝑊 R= 𝑏𝑊 𝑎× 100 𝑎 Wa = weight of the tablet before absorption. Wb = weight of the tablet after absorption. 5. Friability (12) The tablets were carefully dedusted prior to testing. Accurately weigh the tablet sample, and place the tablets in the drum. Rotate the drum 100 times, and the tablets were removed. The tablets were then reweighed after removal of fines and the percentage of weight loss was calculated. A maximum mean weight loss from the three samples of not more than 1.0% is considered acceptable for most products. F% = 𝑊𝐴−𝑊𝐵 𝑊𝐵 × 100 6. Disintegration test The disintegration time was measured using disintegration test apparatus as per the USP. One tablet was placed in each tube of the basket. The basket with the bottom surface made of a stainless-steel screen (mesh no.10) were immersed in water bah a 37± 2°C. The time required for complete disintegration of the tablet in each tube was determined using a stop watch. 7. Drug Content Ten tablets from each batch were powdered. The powdered sample equivalent to 100 mg of drug was transferred to a volumetric flask. 100 ml of 0.1 N HCl was added, mixed and filtered. 1 ml of filtrate was diluted to 10 ml with 0.1N HCl and analyzed against blank by UV spectrophotometer at 271nm. (UV 1800, Shimadzu) 8. Fourier Transform Infrared (FTIR) spectroscopy FTIR spectra were recorded by mixing dried powder with potassium bromide (KBr) of IR grade using a Jasco, FTIR-4100 model. Pellets were prepared with KBr by means of hydraulic press at a pressure of 50 units. The scanning range was 400 to 4000 cm-1. Results and Discussion: The study was designed to evaluate the immediate release tablets of Tramadol hydrochloride. No interference of placebo was found at λ max of Tramadol HCL. Hence, the UV method used for estimation of Tramadol HCL in formulation is specific. The results of the linearity of Tramadol HCl are summarised in Table-3. The calibration curve of % concentrations of Tramadol hydrochloride versus respective absorbance was plotted (Fig.2). The representative linear equation was y = 0.005x+0.014, where x is concentration and y is the absorbance. The correlation coefficient was 0.999, indicating good linearity in the concentration range of 10100 µg/ml. All the batches were evaluated for flow properties. The angle of repose for all the batches was found to be between 28.68 °to 38.76° indicating good flow. A Hausner’s Ratio between 1.06 to 1.30 and Compressibility index between 5% - 22% indicated good flow. Thus, the formulation showed the required flow properties for direct compression. The values for angle of repose, Hausner’s Ratio and Compressibility Index of individual batches are represented in Table 1. All the batches were evaluated for physical parameters such as weight variation, drug content, hardness, friability, water absorption ratio and disintegration time. The tablets with different formulations were found to be between the weight ranges of 195 to 204 mg. The drug content of tablets with different formulations was found to be highly uniform within the range of 97.94% to 99.45%. A hardness value of tablets for all the batches was maintained between 3.26 to 4.01Kp. All the batches satisfied the friability requirement as the percent friability values of tablets were less than 1%. Wetting time is used as an indicator of the ease of tablet disintegration and found to be 16-30sec. Water absorption ratio ranged from 18.2436.37.Disintegration time for B9 batch was found to be more as compared to other batches. All the other batches showed the disintegration time below 5 minutes. The hardness, friability, drug content, disintegration time, water absorption ratio and wetting time values are represented in Table 2. FT-IR studies revealed that there was no physico-chemical interaction between Tramadol HCL and other excipients. It is showed in fig.1 Conclusion: In the present work efforts have been made to develop Tramadol HCl Immediate release tablet as a promising approach to give the rapid action by using different Superdisintegrants. The results showed that the disintegration time was increased with increasing concentration of superdisintegrants. Sodium starch glycolate, Croscarmellose Sodium and Starcap 1500 was compared and the best formulation (F9) containing 10% Sodium starch glycolate showed minimum disintegration time. Reference: 1. Lehman KA. Tramadol hydrochloride in acute pain. Drugs. 1997; 53:25– 33. [PubMed] 2. Gurudev Singh Raina, Rajeev Taliyan and P.L. Sharma, Pathophysiology of neuropathic pain: a systemic review, IJPSR, Vol. 3, Issue 10,2012 3. Robinson JR and Lee VH. Controlled Drug Delivery Systems. 2nd edition New York: Marcel Dekker inc, 2005. 4. Kumar P, Singh S e. al. “Development And Biopharmaceutical Evaluation Of Extended Release Formulation Of Tramadol Hydrochloride Based On Osmotic Technology”, Acta Pharm, 2009, 59 (1):15–30. 5. Raval SB, Prajapati R., et al. “Formulation And Evaluation Of Tramadol Hydrochloride Mouth Dissolving Tablet”,Journal of Global Pharma Technology, 2010; 2(11):17-22. 6. O'Neil MJ, Heckelman PE, The Merck Index: An Encyclopedia of Chemicals, Drugs, and Biologicals, ,13th edition., Merck and Co., Inc., USA, 2001. 7. Gillian M , Tramadol Sustained-Release Capsules Keating, , Adis Drug Profile Drugs: Volume 66 - Issue 2 - pp 223-230,2006 8. Byline: K. Srinivasan, J. Alex, A. Shirwaikar, S. Jacob, M. Sunil Kumar, S. Prabu, Simultaneous derivative spectrophotometric estimation of aceclofenac and tramadol with paracetamol in combination solid dosage forms, Indian Journal of Pharmaceutical Sciences ,1 July 2007 9. Staniforth, J.N. (1996). Powder flow. In: Aulton M. E. (Ed). Pharmaceutics- the science of dosage form design. Churchill Livingston, pp 600-615. 10. M. C. Gohel, A. F. Amin, Munira Momin, Seema Bazaz, M. K. panchal, “Preliminary investigations in matrix based tablet formulations of diclofenac sodium containing succinic acid treated guar gum.” in Bollettino Chimico Farmaceutico 137(6) 1998. 11. United States of Pharmacopoeia Convention (USP), USP-24 NF-19, Rockville, USA, 1999. 12. Yeole CN, Darekar SS, et. al. Formulation and Evaluation of Immediate Release Tablet of Paroxetine Hydrochloride,Journal of Pharmacy Research, 2010, 3(8):17361738 Table 1: Formulation of Tramadol hydrochloride immediate release Tablets. Ingredients Batch code (mg) B1 B2 B3 B4 B5 B6 B7 B8 B9 Tramadol HCL 50 50 50 50 50 50 50 50 50 MCC 143 141 138 143 141 138 143 141 138 Starcap 1500 05 07 10 _ _ _ _ _ _ Crosscarmellose Sodium _ _ _ 05 07 10 _ _ _ Sodium starch Glycolate (SSG) _ _ _ _ _ _ 05 07 10 Magnesium stearate 2 2 2 2 2 2 2 2 2 Table 2: Evaluation of Precompressed powder blend Sr. No 1 Properties B1 B2 B3 B4 B5 B6 B7 B8 B9 Bulk density(g/ml) 0.56 0.54 0.46 0.57 0.65 0.42 0.44 0.52 0.42 2 Tapped density(g/ml) 0.62 0.70 0.51 0.62 0.72 0.55 0.53 0.58 0.55 3 Carr’s index 6.56 22.52 11 9.9 7.03 23.63 15 10.34 23.63 4 Hausner’s ratio 1.06 1.28 1.12 1.14 1.08 1.30 1.12 1.11 1.30 5 Flow rate(sec) 12 9.99 13.0 11 7.0 15.0 10.0 10.0 15.0 6 Angle of repose 37.1 37.65 30.54 34.6 32.42 31.80 31.54 38.65 31.80 8 Compressibility 5.9 22.32 12.11 11 6.56 30.95 13.11 10.52 30.95 Table 3: Evaluation of immediate release tablets of Tramadol HCl Batch code Weight variation (mg) Hardness (kg/cm2) Friability (%) Drug Content (%) Disintegration time (sec.) Water absorption ratio (%) Wetting time (sec.) B1 198-202 3.71 ±0.02 0.42±0.03 98.10 65±2.00 25.89±1.11 21.00± 1.12 B2 197-203 3.83 ±0.12 0.33±0.06 98.65 52±2.00 18.24±2.13 19.00± 0.61 B3 196-201 4.01 ±0.26 0.24±0.05 99.35 45±1.00 19.45±2.10 16.33± 1.55 B4 198-202 3.81 ±0.03 0.53±0.05 99.29 34±0.00 32.45±1.63 23.87± 0.36 B5 197-201 3.26 ±0.13 0.43±0.01 99.20 31±1.00 28.69±1.55 22.67± 0.52 B6 195-204 3.49 ±0.23 0.52±0.04 98.88 27±2.00 29.09±1.52 22.34± 1.58 B7 199-203 3.72 ±0.06 0.35±0.02 97.94 33±2.00 35.89±1.32 30.39± 0.58 B8 198-204 3.64 ±0.01 0.38±0.01 99.45 24±2.00 36.37±1.96 25.01± 1.01 B9 196-201 4.10 ±0.01 0.42±0.03 98.96 21±1.00 37.09±1.92 27.33± 0.59 Table 3: Absorbance of different concentrations of Tramadol HCL in 0.1 N HCL Concentration (µg/ml) Absorbance 10 0.067 20 0.1445 40 0.2352 60 0.344 80 0.4158 100 0.5301 120 0.6211 140 0.7466 160 0.8552 Figure 1. FT-IR of Tramadol Hydrochloride. Fig. 2: Calibration Curve for Tramadol HCL in 0.1 N HCL