X RAY - Over-blog

advertisement

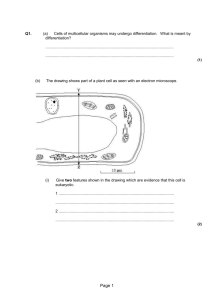

Southeast university School Of Science Bsc In Textile Engineering Course Title: Textile Physics-01 Course Code: tex-2037 Assignment On: 01. a)X ray diffraction method for fiber investigation b) Electron microscope 02.Details description of all factors related to luster 03. Details description of Birefringence Submitted To Lecturer Morshed Rahman Dept. of Textile Engineering Submitted By Md.Nazmul Hossain Khan ID:2012000400022 Batch:19th ,Section:A Dept. of Textile Engineerin Date of Submission: X-ray diffraction method for fiber investigation Definition X-ray fiber diffraction is a technique that enables structure determination of fibrous or polymeric molecules based on the ordered arrangement of molecular structure along a fiber axis. Diffraction patterns are generated by the X-ray scattering from the molecular organization of the fibrous molecule. The fibrous structures are generally cylindrically symmetric around an uniaxial direction, which results in diffraction data with a characteristic four quadrant symmetry, with diffraction signals arranged symmetrically across the "meridian" (usually vertical) and "equator" (horizontal) (Fig. 1). Unlike single crystal diffraction, diffraction signals are often overlapping and, depending on the quality of the diffracting sample, may show diffraction peaks arranged along "layer lines." X-radiation (composed of X-rays) is a form of electromagnetic radiation. X-rays have a wavelength in the range of 0.01 to 10 nanometers, corresponding to frequencies in the range 30 petahertz to 30 exahertz (3×1016 Hz to 3×1019 Hz) and energies in the range 100 eV to 100 keV. The wavelengths are shorter than those of UV rays and longer than those of gamma rays. Fig1: Fiber diffraction geometry changes as the fiber is tilted fig2: 3D representation of the reciprocal space filled with scattering data 1) In Bragg’s law, when x-rays are scattered from a crystal lattice, peaks of scattered intensity are observed which correspond to the following conditions: a.The angle of incidence = angle of scattering. b.The path length difference is equal to an integer number of wavelengths. 2) The condition for maximum intensity contained in Bragg's law above allow us to calculate details about the crystal structure, or if the crystal structure is known, to determine the wavelength of the x-rays incident upon the crystal. n λ = 2d sin θ A crystal can be regarded as made up of layers of atoms, themselves regular in their two-dimensional plan, stacked regularly on top of one another. Although analysis of the diffraction from such a three-dimensional lattice is more complicated than for a simple grating, it does result in a very similar equation; for it can be shown that, if a beam of X-rays is directed at a crystal, it is strongly reflected whenever it strikes layers of atoms at an angle θ, shown in Fig. above, such that: nλ = 2d sinθ where n= integer λ =is the wavelrngth of x- ray d is the distance between atomic layes 3) The condition that a particular reflection should occur is that the layer of atoms should make the required angle with the X-ray beam. This will happen for a series of orientations of the crystals distributed around a cone. The X-rays will be reflected around a cone of twice this angle, as show in the fig Layers of atoms giving rise to a particular reflection will make a constant angle, φ, with this crystal axis, but, if there is no preferred orientation perpendicular to the fiber axis, the layers can occur at a series of positions distributed around the fiber axis on a cone, as shown in Fig. 1.11. If an X-ray beam is directed at right angles to the fiber axis, the reflections will now occur, not round a whole cone, but only at those four angles at which the cone of Fig. 1.10 (defining the characteristic angles of reflection) intersects with the cone of Fig. 1.11 (defining the angles at which the particular layers of atoms occur). This is illustrated in Fig. X-ray diffraction is a most important tool for the study of fiber structure: Firstly, because it gives information at the most important level of fine structure; & Secondly, because focusing of X-rays is not possible, so that diffraction methods have to be used. Three advances have made the technique more powerful than was available to the pioneers of X-ray diffraction: Arrays of detectors give enhanced quantitative information on the diffraction pattern; Computer software then enables the data to be analyzed and interpreted; & The increased power of synchrotron radiation reduces exposure times and allows small spot sizes to be used. Electron Microscopy The electron microscope is a type of microscope that uses a beam of electrons to create an image of the specimen. It is capable of much higher magnifications and has a greater resolving power than a light microscope, allowing it to see much smaller objects in finer detail. They are large, expensive pieces of equipment, generally standing alone in a small, specially designed room and requiring trained personnel to operate them. The History of EM The first electromagnetic lens was developed in 1926 by Hans Busch. According to Dennis Gabor, the physicist Leó Szilárd tried in 1928 to convince Busch to build an electron microscope, for which he had filed a patent. The German physicist Ernst Ruska and the electrical engineer Max Knoll constructed the prototype electron microscope in 1931, capable of fourhundred-power magnification; the apparatus was the first demonstration of the principles of electron microscopy.[4] Two years later, in 1933, Ruska built an electron microscope that exceeded the resolution attainable with an optical (light) microscope.[4] Moreover, Reinhold Rudenberg, the scientific director of Siemens-Schuckertwerke, obtained the patent for the electron microscope in May 1931. In 1932, Ernst Lubcke of Siemens & Halske built and obtained images from a prototype electron microscope, applying concepts described in the Rudenberg patent applications.[5] Five years later (1937), the firm financed the work of Ernst Ruska and Bodo von Borries, and employed Helmut Ruska (Ernst’s brother) to develop applications for the microscope, especially with biological specimens.[4][6] Also in 1937, Manfred von Ardenne pioneered the scanning electron microscope.[7] The first practical electron microscope was constructed in 1938, at the University of Toronto, by Eli Franklin Burton and students Cecil Hall, James Hillier, and Albert Prebus; and Siemens produced the first commercial transmission electron microscope (TEM) in 1939.[8] Although contemporary electron microscopes are capable of two million-power magnification, as scientific instruments, they remain based upon Ruska’s prototype. Types of Electron Microscopes Transmission Electron Microscope (TEM) The original form of electron microscopy, Transmission electron microscopy (TEM) involves a high voltage electron beam emitted by a cathode and formed by magnetic lenses. The electron beam that has been partially transmitted through the very thin (and so semitransparent for electrons) specimen carries information about the structure of the specimen. The spatial variation in this information (the "image") is then magnified by a series of magnetic lenses until it is recorded by hitting a fluorescent screen, photographic plate, or light sensitive sensor such as a CCD (charge-coupled device) camera. The image detected by the CCD may be displayed in real time on a monitor or computer. Transmission electron microscopes produce two-dimensional, black and white images.Resolution of the TEM is also limited by spherical and chromatic aberration, but a new generation of aberration correctors has been able to overcome or limit these aberrations. Software correction of spherical aberration has allowed the production of images with sufficient resolution to show carbon atoms in diamond separated by only 0.089 nm and atoms in silicon at 0.078 nm at magnifications of 50 million times. The ability to determine the positions of atoms within materials has made the TEM an indispensable tool for nanotechnologies research and development in many fields, including heterogeneous catalysis and the development of semiconductor devices for electronics and photonics. In the life sciences, it is still mainly the specimen preparation which limits the resolution of what we can see in the electron microscope, rather than the microscope itself. At JIC we have a high voltage (200kV) TEM, which was installed in 2008. We have two digital cameras on it, one is higher resolution than the other, so that the need for developing and printing film has been negated. Our TEM is designed for use with biological samples and is capable of resolving to better than 1nm. It is also capable of 3-D tomography which involves taking a succession of images whilst tilting the specimens through increasing angles, which can then be combined to form a three-dimensional image of the specimen. Scanning Electron Microscope (SEM) Unlike the TEM, where the electrons in the primary beam are transmitted through the sample, the Scanning Electron Microscope (SEM) produces images by detecting secondary electrons which are emitted from the surface due to excitation by the primary electron beam. In the SEM, the electron beam is scanned across the surface of the sample in a raster pattern, with detectors building up an image by mapping the detected signals with beam position.SEM image of a fly's foot plate showing the drawing of a fly's foot SEM image of a fly's foot taken at JIC in 2006 From "Micrographia", by Robert Hooke, 1665: plate showing the drawing of a fly's foot TEM resolution is about an order of magnitude better than the SEM resolution. Our TEM can easily resolve details of 0.2nm. Our two SEMs at JIC are both relatively recent acquisitions and are high-resolution instruments capable of about 2 nm resolution on biological samples. Because the SEM image relies on electron interactions at the surface rather than transmission it is able to image bulk samples and has a much greater depth of view, and so can produce images that are a good representation of the 3D structure of the sample. SEM images are therefore considered to provide us with 3D, topographical information about the sample surface but will still always be only in black and white. In the SEM, we use much lower accelerating voltages to prevent beam penetration into the sample since what we require is generation of the secondary electrons from the true surface structure of a sample. Therefore, it is common to use low KV, in the range 1-5kV for biological samples, even though our SEMs are capable of up to 30 kV.At JIC we currently have two SEMs, both with high-resolution capabilities, digital imaging facilities and cryo-systems which enable them to be used for looking at frozen-hydrated specimens. Reflection electron microscope (REM) In the reflection electron microscope (REM) as in the TEM, an electron beam is incident on a surface but instead of using the transmission (TEM) or secondary electrons (SEM), the reflected beam of elastically scattered electrons is detected. This technique is typically coupled with reflection high energy electron diffraction (RHEED) and reflection high-energy loss spectroscopy (RHELS). Another variation is spin-polarized low-energy electron microscopy (SPLEEM), which is used for looking at the microstructure of magnetic domains. Sample Preparation Materials to be viewed in an electron microscope generally require processing to produce a suitable sample. This is mainly because the whole of the inside of an electron microscope is under high vacuum in order to enable the electron beam to travel in straight lines. The technique required varies depending on the specimen, the analysis required and the type of microscope: Cryofixation - freezing a specimen rapidly, typically to liquid nitrogen temperatures or below, that the water forms ice. This preserves the specimen in a snapshot of its solution state with the minimal of artefacts. An entire field called cryo-electron microscopy has branched from this technique. With the development of cryo-electron microscopy, it is now possible to observe virtually any biological specimen close to its native state. Fixation - a general term used to describe the process of preserving a sample at a moment in time and to prevent further deterioration so that it appears as close as possible to what it would be like in the living state, although it is now dead. In chemical fixation for electron microscopy, glutaraldehyde is often used to crosslink protein molecules and osmium tetroxide to preserve lipids. Dehydration - removing water from the samples. The water is generally replaced with organic solvents such as ethanol or acetone as a stepping stone towards total drying for SEM specimens or infiltration with resin and subsequent embedding for TEM specimens. Embedding - infiltration of the tissue with wax (for light microscopy) or a resin (for electron microscopy) such as araldite or LR White, which can then be polymerised into a hardened block for subsequent sectioning. Sectioning - the production of thin slices of the specimen. For light microscopy, the sections can be a few micrometres thick but for electron microscopy they must be very thin so that they are semitransparent to electrons, typically around 90nm. These ultra-thin sections for electron microscopy are cut on an ultramicrotome with a glass or diamond knife. Glass knives can easily be made in the laboratory and are much cheaper than diamond, but they blunt very quickly and therefore need replacing frequently. Staining - uses heavy metals such as lead and uranium to scatter imaging electrons and thus give contrast between different structures, since many (especially biological) materials are nearly "transparent" to the electron beam. By staining the samples with heavy metals, we add electron density to it which results in there being more interactions between the electrons in the primary beam and those of the sample, which in turn provides us with contrast in the resultant image. In biology, specimens can be stained "en bloc" before embedding and/or later, directly after sectioning, by brief exposure of the sections to solutions of the heavy metal stains. Freeze-fracture and freeze-etch - a preparation method particularly useful for examining lipid membranes and their incorporated proteins in "face on" view. The fresh tissue or cell suspension is frozen rapidly (cryofixed), then fractured by simply breaking or by using a microtome while maintained at liquid nitrogen temperature. The cold, fractured surface is generally "etched" by increasing the temperature to about -95°C for a few minutes to let some surface ice sublime to reveal microscopic details. For the SEM, the sample is now ready for imaging. For the TEM, it can then be rotary-shadowed with evaporated platinum at low angle (typically about 6°) in a high vacuum evaporator. A second coat of carbon, evaporated perpendicular to the average surface plane is generally performed to improve stability of the replica coating. The specimen is returned to room temperature and pressure, and then the extremely fragile "shadowed" metal replica of the fracture surface is released from the underlying biological material by careful chemical digestion with acids, hypochlorite solution or SDS detergent. The floating replica is thoroughly washed from residual chemicals, carefully picked up on an EM grid, dried then viewed in the TEM. Sputter Coating - an ultra-thin coating of electrically-conducting material, deposited by low vacuum coating of the sample. This is done to prevent charging of the specimen which would occur because of the accumulation of static electric fields due to the electron irradiation required during imaging. It also increases the amount of secondary electrons that can be detected from the surface of the sample in the SEM and therefore increases the signal to noise ratio. Such coatings include gold, gold/palladium, platinum, chromium etc. Disadvantages of Electron Microscopy Electron microscopes are very expensive to buy and maintain. They are dynamic rather than static in their operation: requiring extremely stable high voltage supplies, extremely stable currents to each electromagnetic coil/lens, continuously-pumped high/ultra-high vacuum systems and a cooling water supply circulation through the lenses and pumps. As they are very sensitive to vibration and external magnetic fields, microscopes aimed at achieving high resolutions must be housed in buildings with special services. A significant amount of training is required in order to operate an electron microscope successfully and electron microscopy is considered a specialised skill. The samples have to be viewed in a vacuum, as the molecules that make up air would scatter the electrons. This means that the samples need to be specially prepared by sometimes lengthy and difficult techniques to withstand the environment inside an electron microscope. Recent advances have allowed some hydrated samples to be imaged using an environmental scanning electron microscope, but the applications for this type of imaging are still limited. Artefacts It must be emphasised from the outset that every electron micrograph is, in a sense, an artefact. Changes in the ultra-structure are inevitable during all the steps of processing that samples must undergo: material is extracted, dimensions are changed and molecular rearrangement occurs. The best thing we can do is to keep these changes to a minimum by understanding the processes involved so that we make informed choices of the best preparative procedures to use for each sample. Artefacts present themselves in many ways: there could be loss of continuity in the membranes, distortion or disorganisation of organelles, empty spaces in the cytoplasm of cells or sharp bends or curves in filamentous structures that are usually straight, such as microtubules and so on. With experience, microscopists learn to recognise the difference between an artefact of preparation and true structure, mainly by looking at the same or similar specimens prepared in the same or a different way. Scanning electron microscopes usually image conductive or semi-conductive materials best. Non-conductive materials can be imaged, either by an environmental scanning electron microscope or more usually by coating the sample with a conductive layer of metal. A common preparation technique is to coat the sample with a layer of conductive material, a few nanometers thick, such as 10nm of gold, from a sputtering machine. This process does, however, have the potential to disturb delicate samples and cover some detail. When using chemical fixation and dehydration as part of the sample preparation, there is often much shrinkage and collapse of delicate structures and so, especially for our interests at JIC in botanical specimens which are highly hydrated, we tend to use the cryo-fixation technique which is far less prone to artefacts.For the TEM, samples are generally prepared by exposure to many nasty chemicals, in order to give good ultra-structural detail which may result in artefacts purely as a result of preparation. This gives the problem of distinguishing artefacts from genuine structures within the specimen, particularly in biological samples. Scientists maintain that the results from various preparation techniques have been compared, and as there is no reason that they should all produce similar artefacts, it is therefore reasonable to believe that electron microscopy features correlate with living cells. In addition, higher resolution work has been directly compared to results from X-ray crystallography, providing independent confirmation of the validity of this technique. Recent work performed on unfixed, vitrified (rapidly frozen, without the use of any chemicals, to form ice without any crystallisation) specimens has also been performed, further confirming the validity of this technique. However, even cryo-fixation techniques are not without their own artefacts of preparation and ice crystal damage, due to the fact that as water freezes it expands, is a common problem when trying to image a large specimen (greater than 200 µm) which cannot be frozen rapidly enough to vitrify the water Birefringence . Birefringence is the optical property of a material having a refractive index that depends on the polarization and propagation direction of light.[1] These optically anisotropic materials are said to be birefringent (or birefractive). The birefringence is often quantified as the maximum difference between refractive indices exhibited by the material. Crystals with asymmetric crystal structures are often birefringent, as well as plastics under mechanical stress. Birefringence is responsible for the phenomenon of double refraction whereby a ray of light, when incident upon a birefringent material, is split by polarization into two rays taking slightly different paths. This effect was first described by the Danish scientist Rasmus Bartholin in 1669, who observed it[2] in calcite, a crystal having one of the strongest birefringences. However it was not until the 19th century that Augustin-Jean Fresnel correctly described the phenomenon in terms of polarization, understanding light as a wave with field components in transverse polarizations (perpendicular to the direction of the wave vector). Fig1:Displacement of light rays with perpendicular fig2: A calcite crystal laid upon a graph paper polarization through a birefringent material. with blue lines showing the double refraction Explanation The simplest (and most common) type of birefringence is that of materials with uniaxial anisotropy. That is, the structure of the material is such that it has an axis of symmetry with all perpendicular directions optically equivalent. This axis is known as the optic axis of the material, and components of light with linear polarizations parallel and perpendicular to it have unequal indices of refraction, denoted ne and no, respectively, where the subscripts stand for extraordinary and ordinary. The names reflect the fact that, if unpolarized light enters the material at some angle of incidence, the component of the incident radiation whose polarization is perpendicular to the optic axis will be refracted according to the standard law of refraction for a material of refractive index no, while the other polarization component, the so-called extraordinary ray will refract at a different angle determined by the angle of incidence, the orientation of the optic axis, and the birefringence What's more, the extraordinary ray is an inhomogeneous wave whose power flow (given by the Poynting vector) is not exactly parallel to the wave vector. This causes a shift in that beam, even when launched at normal incidence, that is popularly observed using a crystal of calcite as photographed above. Rotating the calcite crystal will cause one of the two images, that of the extraordinary ray, to rotate slightly around that of the ordinary ray which remains fixed. When the light propagates either along or orthogonal to the optic axis, such a lateral shift does not occur. In the first case, both polarizations see the same effective refractive index, so there is no extraordinary ray. In the second case the extraordinary ray propagates at a different phase velocity (corresponding to ne) but is not an inhomogeneous wave. A crystal with its optic axis in this orientation, parallel to the optical surface, may be used to create a waveplate, in which there is no distortion of the image but an intentional modification of the state of polarization of the incident wave. For instance, a quarter-wave plate is commonly used to create circular polarization from a linearly polarized source. The more general case of biaxially anisotropic materials, also known as trirefringent[citation needed materials, is substantially more complex. Then there are three refractive indices corresponding to three principal axes of the crystal. Generally both polarizations are extraordinary rays with different effective refractive indices which can be determined using the index ellipsoid for a given polarization vector. Sources of optical birefringence While birefringence is usually obtained using an anisotropic crystal, it can result from an optically isotropic material in a few ways: Stress birefringence results when isotropic materials are stressed or deformed such that the isotropy is lost in one direction (i.e., stretched or bent). Example By the Kerr effect, whereby an applied electric field induces birefringence at optical frequencies through the effect of nonlinear optics; By the Faraday effect, where a magnetic field causes some materials to become circularly birefringent (having slightly different indices of refraction for left and right handed circular polarizations), making the material optically active until the field is removed; By self or forced alignment of highly polar molecules such as lipids, some surfactants or liquid crystals, that generate highly birefringent thin films. Examples of uniaxial birefringent materials The best-studied birefringent materials are crystalline; the refractive indices (at wavelength ~ 590 nm) of several such uniaxial crystals are tabulated to the right .[4] Many plastics are birefringent, because their molecules are 'frozen' in a stretched conformation when the plastic is molded or extruded. [5] For example, ordinary cellophane is birefringent. Polarizers are routinely used to detect stress in plastics such as polystyrene and polycarbonate. Cotton (gossypium hirsutum) fiber is birefringent because of high levels of cellulosic material in the fiber's secondary cell wall. Inevitable manufacturing imperfections in optical fiber leads to birefringence which is one cause of pulse broadening in fiber-optic communications. Such imperfections can be geometrical (lack of circular symmetry), due to stress applied to the optical fiber, and/or due to bending of the fiber. Birefringence is intentionally introduced (for instance, by making the cross-section elliptical) in order to produce polarization-maintaining optical fibers.In addition to anisotropy in the electric polarizability (electric susceptibility), anisotropy in the magnetic polarizability magnetic permeability]) will also cause birefringence. However at optical frequencies, values of magnetic permeability for natural materials are not measurably different from µ0 so this is not a source of optical birefringence in practice. Uniaxial materials, at 590 nm[4] Material Crystal system no ne Δn barium borate BaB2O4 Trigonal 1.6776 1.5534 -0.1242 beryl Be3Al2(SiO3)6 Hexagonal 1.602 1.557 -0.045 calcite CaCO3 Trigonal 1.658 1.486 -0.172 ice H2O Hexagonal 1.309 1.313 +0.004 lithium niobate LiNbO3 Trigonal 2.272 2.187 -0.085 magnesium fluoride MgF2 Tetragonal 1.380 1.385 +0.006 quartz SiO2 Trigonal 1.544 1.553 +0.009 Uniaxial materials, at 590 nm[4] Material Crystal system no ne Δn ruby Al2O3 Trigonal 1.770 1.762 -0.008 rutile TiO2 Tetragonal 2.616 2.903 +0.287 sapphire Al2O3 Trigonal 1.768 1.760 -0.008 silicon carbide SiC Hexagonal 2.647 2.693 +0.046 tourmaline (complex silicate ) Trigonal 1.669 1.638 -0.031 zircon, high ZrSiO4 Tetragonal 1.960 2.015 +0.055 zircon, low ZrSiO4 Tetragonal 1.920 1.967 +0.047 Fast and slow rays For a given propagation direction, in general there are two perpendicular polarizations for which the medium behaves as if it had a single effective refractive index. In a uniaxial material, these polarizations are called the extraordinary and the ordinary ray (e and o rays), with the ordinary ray having the effective refractive index . A biaxial crystal is characterized by three refractive indices α, β, and γ applying to its principal axes. A wave in a specified direction will consist of two polarization components with generally different effective refractive indices. The so-called slow ray is the component for which the material has the higher effective refractive index (slower phase velocity), while the fast ray has a lower effective refractive index. For a uniaxial material with the z axis defined to be the optical axis, the effective refractive indices are as in the table on the right. For rays propagating in directions other than z, the effective refractive index of the extraordinary ray is in between and , depending on the angle between the polarization vector and the z axis. The effective refractive index can be determined using the index ellipsoid. Effective refractive indices in negative uniaxial materials Propagation direction Ordinary ray Extraordinary ray Polarization neff Polarization Z xy-plane n/a xy-plane xy-plane z xz-plane Y xz-plane Other analogous to xz-plane neff n/a Fig: Rays passing through a positively birefringent material. The incident light has parallel and perpendicular polarisation components (linear polarization at 45º the optic axis). The optic axis is perpendicular to the direction of the perpendicular component of incident ray, so the ray polarized parallel to the optic axis has a greater refractive index than the ray polarized perpendicular to it. Positive or negative Uniaxial birefringence is classified as positive when the extraordinary index of refraction ne is greater than the ordinary index no. Negative birefringence means that Δn = ne - no is less than zero.[6] In other words, the polarization of the fast (or slow) wave is perpendicular to the optical axis when the birefringence of the crystal is positive (or negative, respectively). The terms "positive" and "negative" are not applied in the case of biaxial crystals, since all three of the principal axes have different refractive indices, rather than two being the same but different from the one that's designated as the optic axis in a uniaxial crystal. Biaxial birefringence Biaxial birefringence, also known as trirefringence[citation needed] , describes an anisotropic material in which the optical properties are not invariant under rotation about a particular axis (the optic axis, in uniaxial crystals). For such a material, the refractive index tensor n, will in general have three distinct eigenvalues that can be labeled nα, nβ and nγ. Biaxial materials, at 590 nm[4] Material Crystal system nα nβ nγ borax Na2(B4O5)(OH)4·8(H2O) Monoclinic 1.447 1.469 1.472 epsom salt MgSO4·7(H2O) Monoclinic 1.433 1.455 1.461 mica, biotite K(Mg,Fe) 3AlSi 3O Monoclinic 10(F,OH) 2 mica, muscovite KAl2(AlSi3O10)(F,OH)2 Monoclinic olivine (Mg, Fe)2SiO4 Orthorhombic perovskite CaTiO3 Orthorhombic topaz Al2SiO4(F,OH)2 Orthorhombic ulexite NaCaB5O6(OH)6•5(H2O) Triclinic 1.595 1.640 1.640 1.563 1.596 1.601 1.640 1.660 1.680 2.300 2.340 2.380 1.618 1.620 1.627 1.490 1.510 1.520 Measurement Birefringence and other polarization based optical effects (such as optical rotation and linear or circular dichroism) can be measured by measuring the changes in the polarization of light passing through the material. These measurements are known as polarimetry. Birefringence of lipid bilayers can be measured using dual polarisation interferometry. This provides a measure of the degree of order within these fluid layers and how this order is disrupted when the layer interacts with other biomolecules. Applications Birefringence is used in many optical devices. Liquid crystal displays, the most common sort of flat panel display, cause their pixels to become lighter or darker through rotation of the polarization (circular birefringence) of linearly polarized light as viewed through a sheet polarizer at the screen's surface. Similarly, light modulators modulate the intensity of light through electrically induced birefringence of polarized light followed by a polarizer. The Lyot filter is a specialized narrowband spectral filter employing the wavelength dependence of birefringence. Wave plates are thin birefringent sheets widely used in certain optical equipment for modifying the polarization state of light passing through it. Birefringence also plays an important role in second harmonic generation and other nonlinear optical components, as the crystals used for this purpose are almost always birefringent. By adjusting the angle of incidence, the effective refractive index of the extraordinary ray can be tuned in order to achieve phase matching which is required for efficient operation of these devices. Fig: Reflective twisted nematic liquid crystal display. Light reflected by surface (6) (or coming from a backlight) is horizontally polarized (5) and passes through the liquid crystal modulator (3) sandwiched in between transparent layers (2,4) containing electrodes. Horizontally polarized light is blocked by the vertically oriented polarizer (1) except where its polarization has been rotated by the liquid crystal (3), appearing bright to the viewer Stress induced birefringence Isotropic solids do not exhibit birefringence. However, when they are under mechanical stress, birefringence results. The stress can be applied externally or is ‘frozen’ in after a birefringent plastic ware is cooled after it is manufactured using injection molding. When such a sample is placed between two crossed polarizers, colour patterns can be observed, because polarization of a light ray is rotated after passing through a birefingent material and the amount of rotation is dependent on wavelength. The experimental method called photoelasticity used for analyzing stress distribution in solids is based on the same principle. Other cases of birefringence Birefringence is observed in anisotropic elastic materials. In these materials, the two polarizations split according to their effective refractive indices which are also sensitive to stress. The study of birefringence in shear waves traveling through the solid earth (the earth's liquid core does not support shear waves) is widely used in seismology. Birefringence is widely used in mineralogy to identify rocks, minerals, and gemstones Theory Birefringence results when a material's permittivity is not describable using a scalar value, but requires a tensor to relate the electric displacement (D) with the electric field (E). Consider a plane wave propagating in an anisotropic medium, with a permittivity tensor ε and assuming no magnetic permeability in the medium: . We shall assume that the electric field of a wave of angular frequency ω can be written in the form: (2) where r is the position vector, t is time, and E0 is a vector describing the electric field at r=0, t=0. Then we shall find the possible wave vectors k using Maxwell's equations from which we obtain: (3a) (3b) where the so-called electric displacement vector field through the permittivity tensor ε: Substituting the definition of conditions: is now related to the electric and eqn. 2 into eqns. 3a-b leads to the (4a) (4b) Eqn. 4b indicates that is orthogonal to the direction of the wavevector k, even though that is no longer generally true for as would be the case in an isotropic medium. To find the allowed values of k, E0 can be eliminated from eq 4a. If eqn 4a is written in Cartesian coordinates with the x, y and z axes chosen in the principal directions of the permitivity tensor ε, then (4c) where the diagonal values are squares of the refractive indices for polarizations along the three principal axes x, y and z. With ε in this form, and noting that the speed of light , eqn. 4a becomes (5a) (5b) (5c) where Ex, Ey, Ez, kx, ky and kz are the components of E0 and k. This is a set of linear equations in Ex, Ey, Ez, and they have a non-trivial solution if the following determinant is zero: (6) Evaluating the determinant of eqn (6), and rearranging the terms, we obtain In the case of a uniaxial material, choosing the optic axis to be in the z direction so that nx=ny=no and nz=ne, this expression can be factored into (8) Setting either of the factors in eqn 8 to zero will define an ellipsoidal surface in space of allowed wave vectors k. The first factor being zero defines a sphere corresponding to ordinary rays, in which the effective refractive index is exactly no. The second defines a spheroid symmetric about the z axis. This solution corresponds to extraordinary rays in which the effective refractive index is in between no and ne. Therefore for any arbitrary direction of propagation, two distinct wavevectors k are allowed corresponding to the polarizations of the ordinary and extraordinary rays. A general state of polarization launched into the medium can be decomposed into two such waves which will then propagate with different k vectors (except in the case of propagation in the direction of the optic axis). For a biaxial material a similar but somewhat more complicated condition on the two waves can be described.[11] Factor Related to Luster 1.Angle of incident: The light falls across the fiber or along the fiber .If a fiber behaves as a perfect reflecting circular cylinder it could reflect light as like figure (a) and (b) It is clear that if the light falls across the fiber,it is reflecter at various angle whwre as if the light falls along the fibers ,here it is reflected at constant angle. 2.Fineness of the fibers: Fibers exhibit a varity of cross sectional shaps and they also vary in section along their length and vary from fiber to fiber .fineness denoteds the size of the cross sectional diamentions of the fiber.As the cross sectional feasure are irregular ,direct determination of the area of cross section is difficult an laborious.some dimensional feature such as sowellen diameter,ribbon width etc,can be determined directly and sone times used to specify the fineness of cotton fiber. The finer the fibers incorporated in a fabric the greater is the number of the individual reflecting surface per unit area of the fabric.The fiber fineness affects the lustre for the same types of smoothness and regularity the coarser fiber will have more luster than the finer fibers Fineness increase------- luster decease Short staple fiber increase------ luster decease Long staple fiber increase--------luster increase Coarser fiber incease------------ luster increase 3.Irregularity of the fiber surface: Irregularity on the surface of the fibers and in its cross-sectional shape will cause the light to be reflected in various direction and will reduce lustre.It is essential that the fibers should be uniform along its length for this reason luster is greater in regular filaments such those of silk and man made fiber. 4.Fiber shape : The particular types of lustre associated with nylon.rayon and silk must be very due to pattern of light reflected from their respective circulas,serrated and triangular shap. Nylon—circular---more luster Viscose---serrated—dull luster Silk---triangular---less luster 5.Maturity of fibers: Maturity of fiber is a characteristic which express the relative degree of thickening of the fiber wall.In other words it is the measure of primary and secondary wall thickness. mature fibers: Mature fibers with well developed cell wall and after swelling it apear rod like from raw stste and it also show no continuous lumen in the longitudinal section of matured fiber. Dead fibers: Dead fibers are those fiber that after sweeling it has a continuous lumen and the wall thickness is less than the ribbon width. Thin wall fibers: Thin wall fibers are those fiber that are not classed as normal or dead,being of intermediate appearance and thickening. Maturity increase---luster increase---reflection increas 6.Presentation: Presentation of a small particle on fibers like TIO2 that minimize the luster of the manmade fibers. when a beam of light falls on the fibers ,it is not only reflected but also transmitted .some of the transmitter light will reflect from the internal surface as fig (a) If the fiber contain small particles e.g TIO2 or cavities as fig (b),these will scatter the transmitted light at varying angles and causes it to emerge as particularly diffuse reflection..TIO2 is used as delustrants in manmade to reduce its luster.