Additive Manufacturing with Plasma Transfer Arc Weld *Tailored

advertisement

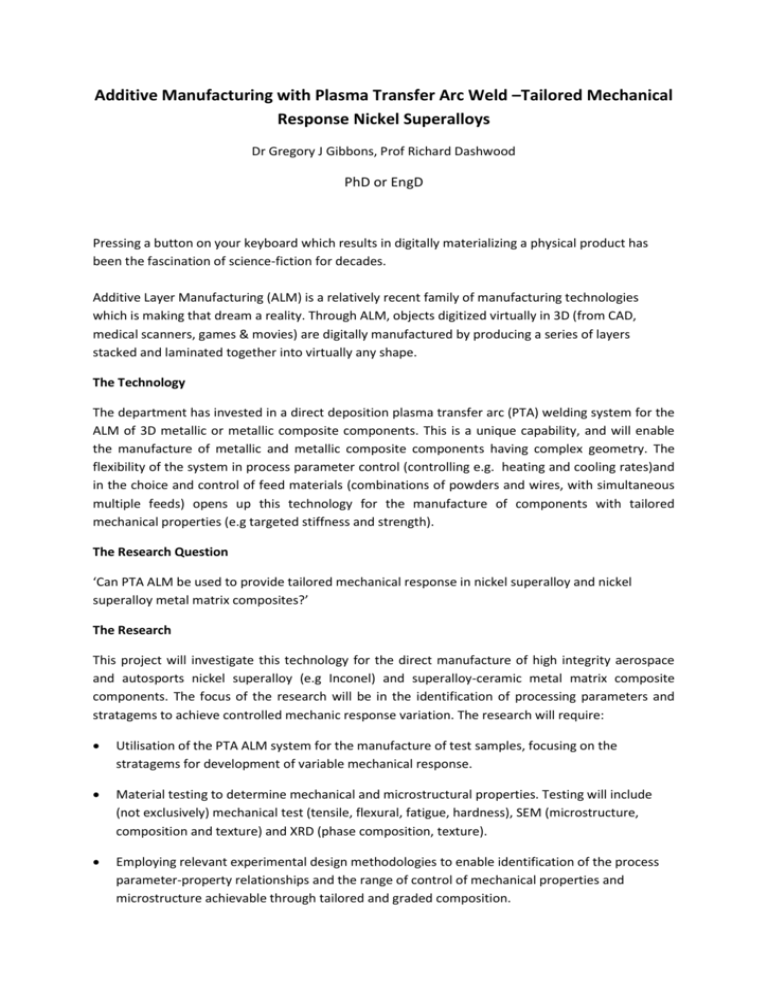

Additive Manufacturing with Plasma Transfer Arc Weld –Tailored Mechanical Response Nickel Superalloys Dr Gregory J Gibbons, Prof Richard Dashwood PhD or EngD Pressing a button on your keyboard which results in digitally materializing a physical product has been the fascination of science-fiction for decades. Additive Layer Manufacturing (ALM) is a relatively recent family of manufacturing technologies which is making that dream a reality. Through ALM, objects digitized virtually in 3D (from CAD, medical scanners, games & movies) are digitally manufactured by producing a series of layers stacked and laminated together into virtually any shape. The Technology The department has invested in a direct deposition plasma transfer arc (PTA) welding system for the ALM of 3D metallic or metallic composite components. This is a unique capability, and will enable the manufacture of metallic and metallic composite components having complex geometry. The flexibility of the system in process parameter control (controlling e.g. heating and cooling rates)and in the choice and control of feed materials (combinations of powders and wires, with simultaneous multiple feeds) opens up this technology for the manufacture of components with tailored mechanical properties (e.g targeted stiffness and strength). The Research Question ‘Can PTA ALM be used to provide tailored mechanical response in nickel superalloy and nickel superalloy metal matrix composites?’ The Research This project will investigate this technology for the direct manufacture of high integrity aerospace and autosports nickel superalloy (e.g Inconel) and superalloy-ceramic metal matrix composite components. The focus of the research will be in the identification of processing parameters and stratagems to achieve controlled mechanic response variation. The research will require: Utilisation of the PTA ALM system for the manufacture of test samples, focusing on the stratagems for development of variable mechanical response. Material testing to determine mechanical and microstructural properties. Testing will include (not exclusively) mechanical test (tensile, flexural, fatigue, hardness), SEM (microstructure, composition and texture) and XRD (phase composition, texture). Employing relevant experimental design methodologies to enable identification of the process parameter-property relationships and the range of control of mechanical properties and microstructure achievable through tailored and graded composition.