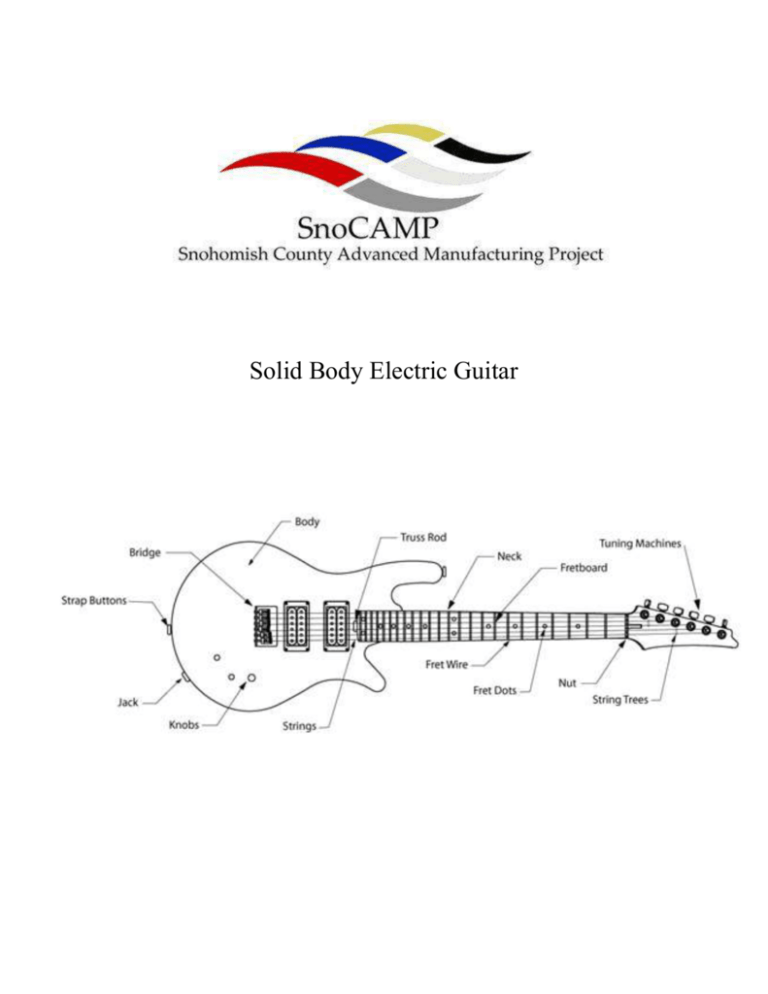

Parts List

advertisement

Solid Body Electric Guitar Parts List Quantity Part Name Picture Description Quantity Part Name 1 Guitar Body 6 Ferrules 1 Neck 2 Strap button w/screws 1 Neck Plate 2 Knobs 4 Neck Screws 2 Potentionmeter 1 Fret board 1 Nut 1 3 Way Switch 1 Fret Dots 1 Output Jack 1 Side Dots 1 Fuse 2 Fret strips (12" strips) 1 Fuse holder 1 Truss rod 1 Capacitor 1 String Guide 6 Tuners 2 String Guide Screws 1 Front (neck) pickup 1 Output Jack Cover 1 Front (neck) pickup Ring 2 Output Jack Screws 4 Pickup adjustment screws 1 Bean Plate 4 Pickup spring 2 Bean Plate Screws 4 Front (neck) pickup screws 1 Strings (set) 4 Rear (bridge) pickup screws 1 Bridge 1 Rear (bridge) pickup 5 Bridge Plate Screws 1 Rear (bridge) pickup Ring 1 Small Allen Wrench 24" 24 AWG Wire in Inches Picture Description Body Styles Available for SnoCAMP Planning □ Determine whether you will be building a guitar with a painted body or a hardwood body that will have a clear finish. □ Pick a neck style that will compliment your body style. □ Visualize how you want to contour your body. □ Determine whether you will be adding any personal touches (i.e. laser engraving). If so, you will need to plan for “when” you laser engrave and how contouring might affect the engraving. □ Always place guitar parts on a matt to protect from scratches, dents, etc. □ Always wax screws before screwing into wood Safety □ □ □ □ Always keep work area clean. Return all tools and supplies to their appropriate storage areas Only use tools and equipment that you have been approved to use. Always wear appropriate PPE when working with dangerous equipment, tools, paint, finish, etc. □ Soldering equipment is hot. Do not touch. Body □ □ □ □ □ □ Mark location and drill 7/8” Jack hole Mark and drill 5/16” holes from electronics pocket to pick ups Drill hole to bridge for ground Mark contour lines of desired shape Contour body with rasps, sureform tools, pneumatic sanding drums, etc. to desired shape. Be sure to avoid no-fly zones. Sand body in preparation for finish (all imperfections must be removed) Continue ONLY after Team Lead or Instructor Approval. *Finishing Body (Hardwood body/Clear finish only) □ Apply sealer □ Apply several (minimum 3) coats of topcoat □ Allow for adequate dry time, lightly sand between coats as needed 1st Coat 2nd Coat 3rd Coat Team Lead or Instructor must initial after each coat. *Finishing Body (Painted body only) □ □ □ Apply primer Swirl dip or other paint method Apply several (minimum 3) coats of topcoat 1st Coat 2nd Coat Team Lead or Instructor must initial after each coat. 3rd Coat Design Headstock (6 in-line only) □ □ □ □ Use Rhino template to design Print design, cut out, transfer to headstock Cut out on band saw Sand any visible saw marks to smooth Fretboard □ Mark center locations for fret dots by drawing diagonal lines Continue ONLY after Team Lead or Instructor Approval. □ Drill ¼” holes at least 1/8” deep using a drill press (be careful not to drill all the way through) □ Glue in wood, plastic, MOP, or other fret dots Neck and Fretboard □ □ □ □ □ Sand on a flat surface (use chalk or light pencil marks as guide) Check truss rod fit Check location of 24th fret Drill pin holds to “dry” test fit before gluing Apply masking tape to groove in neck to prevent glue from going in slot while spreading; be sure to remove tape before applying fret board Continue ONLY after Team Lead or Instructor Approval. □ Glue fret board to neck. Use rubber bands in place of clamps □ Remove truss rod. Clean glue off truss rod. Repeat until no glue appears on rod. Sanding and Finishing Neck □ □ □ □ Check for straightness (use metal rule); adjust truss rod as needed Sand fret board to neck on flat surface; do not use power sander Sand 12” radius to fret board using aluminum radius sanding bar Apply Tru-Oil finish Continue ONLY after Team Lead or Instructor Approval. □ Drill holes for side dots □ Glue side dots, cut flush Fretting □ □ □ □ □ □ □ □ □ Clean fret wire with mineral spirits and rag to remove grime Bend fret wire to 12” radius (or smaller) using fret wire bender Tap in one corner using fretting hammer Seat with arbor press; be sure to use neck caul Cut wire close to ends with end nippers; be sure not lift up when cutting Can use super glue on ends if needed File frets flat (can use painters tape on neck to protect) Bevel frets to approximately 35˚ Debur ends using diamond fret file Continue ONLY after Team Lead or Instructor Approval. Electronics & Hardware □ Solder components according to wiring diagram on page 8 □ Use wire harness to make most connections before the wiring is placed into the guitar (potentiometers and output jack) □ Install bridge ground wire □ Install wiring harness □ Make final connections with pickups and bridge ground □ Secure potentiometers with washers and nuts □ Secure the output jack to the jack plate & screw plate to body □ Test connections Continue ONLY after Team Lead or Instructor Approval □ Place bean cover and secure with two screws Final Assembly □ □ □ □ □ □ □ Install ferrules Connect pickup springs to pickup rings; secure pickups to body Install tuners (may have to ream existing holes) Install strap buttons (be sure guitar is balanced) Install string nut (may have to sand/file nut blank) Screw the neck to the body using neck plate and 1¾” #8 screws String guitar (Treble on the right/bass on the left (as seen from the front) leaving the strings slightly loose □ Install string guide □ Set string action using gauge (file nut or change saddle) □ Intonate guitar (see separate handout) Name: ___________________________________ Day Date Description of Work Done Goal(s) Monday What was accomplished? Goal(s) Tuesday What was accomplished? Goal(s) Wednesday What was accomplished? Goal(s) Thursday What was accomplished? Goal(s) Friday What was accomplished? Hours Start Time End Time Start Time End Time Start Time End Time Start Time End Time Start Time End Time Week 1 Tota l Hours Monday’s Notes Tuesday’s Notes Wednesday’s Notes Thursday’s Notes Friday’s Notes