Responsibilities as Project and third party Inspector

advertisement

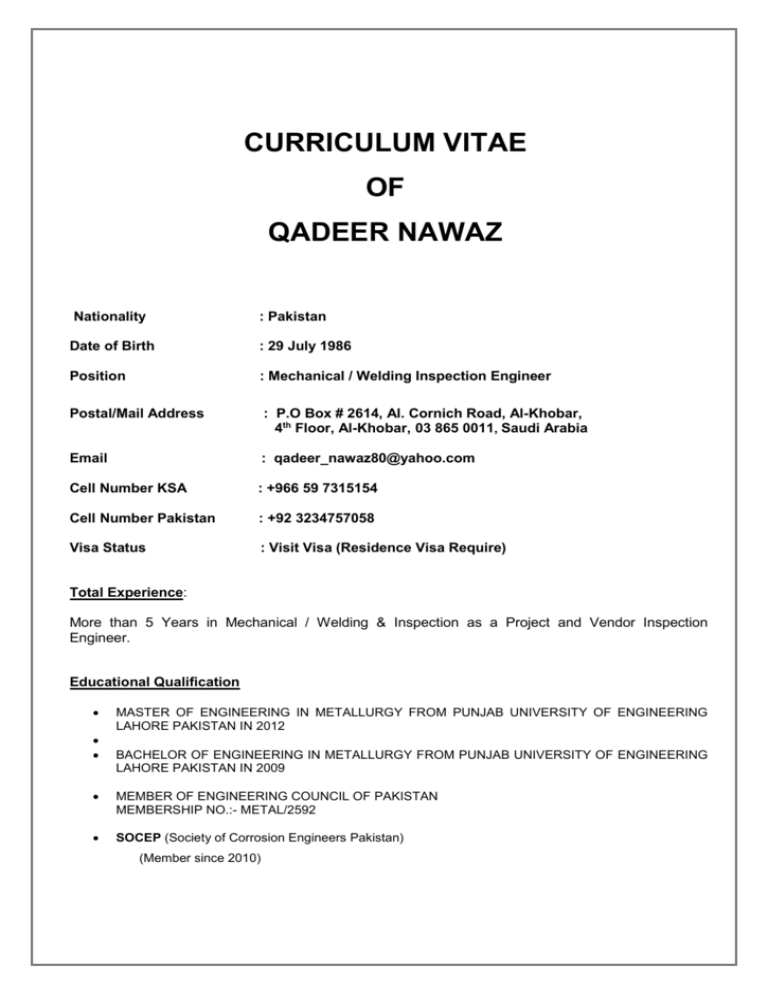

CURRICULUM VITAE OF QADEER NAWAZ Nationality : Pakistan Date of Birth : 29 July 1986 Position : Mechanical / Welding Inspection Engineer Postal/Mail Address : P.O Box # 2614, Al. Cornich Road, Al-Khobar, 4th Floor, Al-Khobar, 03 865 0011, Saudi Arabia Email : qadeer_nawaz80@yahoo.com Cell Number KSA : +966 59 7315154 Cell Number Pakistan : +92 3234757058 Visa Status : Visit Visa (Residence Visa Require) Total Experience: More than 5 Years in Mechanical / Welding & Inspection as a Project and Vendor Inspection Engineer. Educational Qualification MASTER OF ENGINEERING IN METALLURGY FROM PUNJAB UNIVERSITY OF ENGINEERING LAHORE PAKISTAN IN 2012 BACHELOR OF ENGINEERING IN METALLURGY FROM PUNJAB UNIVERSITY OF ENGINEERING LAHORE PAKISTAN IN 2009 MEMBER OF ENGINEERING COUNCIL OF PAKISTAN MEMBERSHIP NO.:- METAL/2592 SOCEP (Society of Corrosion Engineers Pakistan) (Member since 2010) COMPUTER SKILLS: Proficiency in Windows 7, MS Excel, MS Word, MS Access and MS Power Point Responsibilities as Project and third party Inspector: Conduct pre inspection meeting on the behalf of client. Review quality documents .ITP, mark intervention points on ITP Hold, witness, review and surveillance as per inspection level. Review and Approval of Quality Assurance Plan/Inspection test procedure. Working as an expeditor if required and requested by client. Conduct External Auditing on the behalf of client. Proficiently Skilled in Construction, Fabrication, Piping, Structural steel, Welding & Inspection works for oil & gas industries. Raw material inspection - Review of Test certificates with respect to Standards, project Specification & Purchase Order. Visual dimensional inspection for Structural Steel materials, Carbon steel, low alloy steel, high alloy steel piping. Witnessed PQT and welder qualification test for different base metals. Review of Radiographic films, PT and MPT. Reviewing of WPS, PQR & WQT. Review of heat treatment charts/PWHT procedures. Review of test packages for Carbon steel, low alloy steel, high alloy steel piping. Witnessing of Pressure testing for Carbon steel, low alloy steel, high alloy steel piping. Witnessing Mechanical, chemical & metallographic examination in laboratories - Tensile, impact, hardness ,bend test, HIC,SSC Test, chemical analysis by spectrometer & metallographic test Conversant with ASME, API standards and codes. Vendor assessment, Expediting & Pre delivery inspection. Conversant with codes and procedures used in the Oil and Gas Industry Onshore & offshore. Overall Supervision of Engineering inspectors and NDT technicians, interpretation and implementing of mandatory codes, standards and specifications, interpretation of radiographs, review/approval of Inspection and Test Plans, Quality plans, and final acceptance of data packages. Day to Day running of site office, vendor & dealing with clients. DETAILED EMPLOYMENT HISTORY From March 2011 to till date working as Inspection Engineer in WELSPUN pipe line Ltd. on the behalf of , M/s NESPAK. Ltd COMPANY POSITION PROJECT DURATION CLIENTS : NESPAK Ltd., Dammam, K.S.A. : Third Party Inspection Engineer : Completion of Water Transmission from Dams of Hili & Yobba & Lith to Al Shouiba Plant (Phase -2) : March 2011 to till date : MOW (Ministry of Water), Yuksel Insaat, etc. COMPANY : Crescent Steel and Allied Products Ltd. POSITION DURATION PROJECT CLIENT JOB TITLE : QA/QC Engineer : May 2009 to April 2011 :Completion of Water Transmission line Karachi, 1st Project, Karachi, Pakistan : Karachi Water & Sewerage Board Karachi Pakistan : Above Ground Piping and Equipment Installation COMPANY POSITION DURATION PROJECT CLIENT JOB TITLE : AL-Ittefaq Sons pvt. Ltd, Pakistan : QA/QC Engineer : August 2006 to May 2009 : Lahore Bulk Water Supply Scheme - 2nd 100 MGD K-II Project Lahore Pakistan : Lahore Water & Sewerage Board Lahore Pakistan : Construction of 90 Km 1800 dia Mild steel Pipeline COMPANY POSITION DURATION PROJECT CLIENT JOB TITLE : AWS Construction Company - Karachi, Pakistan : QA/QC Inspector : June 2006 to August 2006 : Ghungroi field & Ghungro to Raj-1 6” dia 18 Km Pipeline Project Pakistan : British Petroleum : Ghungroi field & Ghungro to Raj-1 6” dia 18 Km Pipeline Project Pakistan Current Major Assignments 1 Working on the behalf of NESPAK inspector under MOW Contract for the manufacturing of Spiral or Helical Seam Arc welded Pipes at Welspun Middle East Pipes LLC Dammam KSA 2 Working on the behalf of NESPAK inspector under MOW Contract for the manufacturing of Longitudinal Seam Arc welded Pipes at Arabian Pipe Company Jubail KSA 3 Third party inspector on the behalf of Yuksel for PQR witnessed and welder qualification, Dammam CODES AND STANDARDS FAMILIAR WITH: API-5L American Petroleum Institute specification for line pipe. API 1104 Cross Country Pipelines. ASME Section IX Welding Procedure and Welders Qualification. AWS D1.1 Structural Welding. ASME Section II Part C Specification Of Electrodes And Filler Wires. ASME Section II Part A Specification Of Base Metals (Ferrous Materials) ANSI B 31.3 Specification of Process Piping ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products ASME section 5 Nondestructive testing. DUTIES AND RESPONSIBILITIES: Responsibilities as QA/QC Welding Inspector Joint Fit-up & Welding Inspection of Pipelines & Plant Piping. Inspection of all Welding Activities. Reviewing of WPS & PQR. Witnessing PQR Mechanical Tests. Witness Welders Qualification Test & Qualifying Welders. Interpretation of Radiography Films according to Code ASME B 31.3 and ASME Section 5. Reviewing of Magnetic Particle & Dye Penetrant Test Reports. Reviewing Post Weld Heat Treatment Reports. Witnessing and Reviewing of Hardness Test. Checking of all QA/QC documents for Hydro Tests. Head Contractors team in QA/QC and Department Coordination meetings. Responsibilities as Project Welding Inspector: Carbon Steel Checking Joint Fit up to Rectify any mismatch. Checking Root of the Joint to Surface of the joint & Rectifying any lack of Fusion or penetration in the root and undercuts of the surface. Selecting the joints percentage for radiography based on project specification. Alloy Steel Checking joint Fit-up, Root & Surface of joint and rectification if there is fault. Checking preheating & post heating of high thickness joint with thermocouples, PWHT machine to maintain temperature of post heating according to specification. Checking preheating of less thickness joints with gas burner heaters with required temp. Tempel stick as per specification. Checking post weld heat treatment of joints to maintain correct heating rate, cooling rate, soaking period Temp. Ranges. Dissimilar Metals Inspection of welding of different varieties of metals such as Carbon Steel, Low CR-MP Alloy Steel (P4, P11, P5, P22) & stainless steel, low Temp, Killed carbon steel, NDT Activities Interpreting the radiographic films according to ASME ANSI B 31.3 and ASME Section 5 for Process piping of refinery construction. Witnessing hardness Test according to specifications. Witnessing Magnetic Test according to specifications. Witnessing Ultrasonic test of wall thickness for Hot tap tie-in pipe surface area. Coordinating and supervising PMI technicians for performing PMI test. Checking the passivation of all stainless steel lines. Welding Procedure and Welders Qualification Reviewing & Inspection Reviewing and approving welding procedure specifications according to ASME section IX from subcontractors. Witnessing procedure qualifications record, witnessing Mechanical, chemical & metallographic examination in laboratories - Tensile, impact, hardness ,bend test, HIC, chemical analysis by spectrometer & metallographic test Reviewing filler wires and electrodes of welding procedure specification according to ASME section 2 part C and also checking while welding inspection. Witnessing welder’s qualifications test and qualifying welders for different base metals, thickness and diameter ranges according to ASME Section-9. Issuing welders identification cards with stamping and signing after qualification. Reviewing PMI test reports As per SAES A-206, L-071 and ASME code Documentation Controlling the welding of joints according to Isometric drawings and checking diameter, thickness, drawing number & class in welding progress report. Reviewing the PWHT charts cooling rate, heating rate, soaking period according to specifications and approving the charts. Review and subsequent approval of the hardness reports according to specifications. Review and approval of the MPI reports. Reviewing the spool, releasing check sheet and mobilizing to site after approval. Review Final Packages for Hydrostatic test. Checking the punch list items as per P & ID and isometric such as pipe supports, Valves, Guides, Shoe Supports and NDT completion. Responsibilities as Project and third party Painting Inspector: Review of inspection and test plan incorporating intervention points on ITP. Conducting Pre Inspection Meeting on the behalf of client. Conduct External Auditing on the behalf of client. Inspection of abrasives used for blasting of steel surface. Inspection of hydrotest report of pipe. Inspection of ultrasonic test of pipe. Inspection of radiographic test of pipe. Inspection of MPI of pipe. Inspection of CVN test of pipe. Inspection of Hardness test of pipe. Inspection of macro examination of pipe. Inspection of bend test of pipe.