app43374-sup-0001-suppinfo01

Supporting Information

Description of Second Flow Field via the Deformation of Polystyrene

Phase in High-density Polyethylene Matrix

Quan-Ping Zhang 1 , Xiao-Chao Xia 2 , Shan He 2 , Jian-Min Feng 2 , Ming-Bo Yang 2 ,

Yin-Tao Li

1

, Yuan-Lin Zhou

1

1

State Key Laboratory Cultivation Base for Nonmetal Composites and Functional

Materials, Southwest University of Science and Technology, Mianyang 621010, PR

China

2

College of Polymer Science and Engineering, State Key Laboratory of Polymer

Materials Engineering, Sichuan University, Chengdu 610065, PR China

Correspondence to: Ming-Bo Yang; Quan-Ping Zhang (E-mail: yangmb@scu.edu.cn

; zhangqp@swust.edu.cn

)

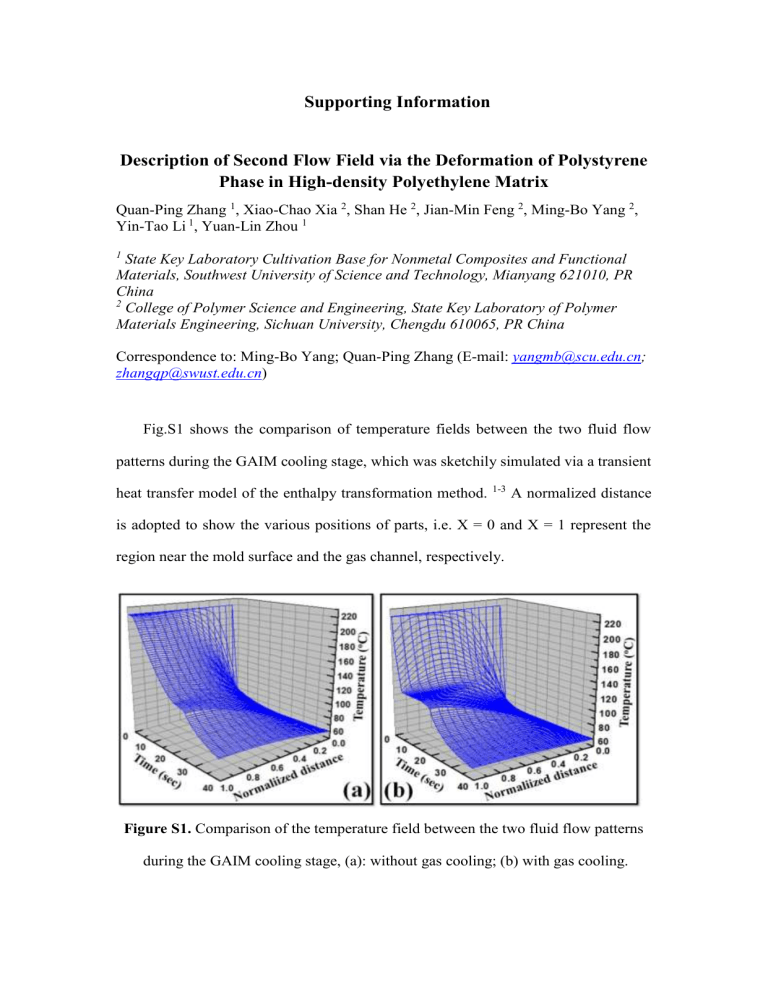

Fig.S1 shows the comparison of temperature fields between the two fluid flow patterns during the GAIM cooling stage, which was sketchily simulated via a transient heat transfer model of the enthalpy transformation method.

1-3

A normalized distance is adopted to show the various positions of parts, i.e. X = 0 and X = 1 represent the region near the mold surface and the gas channel, respectively.

Figure S1.

Comparison of the temperature field between the two fluid flow patterns during the GAIM cooling stage, (a): without gas cooling; (b) with gas cooling.

Since gas cooling was imported by a change of fluid flow pattern, the temperature of gas channel zone was markedly reduced and reached to about 119.5 °C for the phase transition initial temperature of HDPE within about 4 seconds rather than 17 seconds for the molding process without gas cooling, as shown in Fig.S1. Meanwhile, the cooling rate in each zone of parts was also improved in comparison with the corresponding zone of common GAIM. Furthermore, the storage modulus of PS is swiftly enhanced when the temperature below 200 o C, 4-5 indicating that the phase motion with micrometer scale in this work was frozen by a fast liquid-solid transformation. As a consequence, the PS fibrils were observed at the gas channel zone, as shown in Fig.S1(a) and Fig.S1(b), instead of the droplets in the previous work.

6 So, it is certain that the deformed PS phase was availably retained with little relaxation behavior in the gas channel zone of GAIM parts.

Figure S2.

Phase morphology of the HDPE/PS blend molded by extrusion.

References

1. B. Yang, X. R. Fu, W. Yang, S. P. Liang, S. Hu and M. B. Yang, Polym. Eng. Sci.

,

2009, 49, 1234-1242.

2. B. Yang, X. R. Fu, W. Yang, L. Huang, J. M. Feng and M. B. Yang, Polym. Eng.

Sci.

, 2008, 48, 1707-1717.

3. B. Yang, X. R. Fu, W. Yang, S. P. Liang,N. Sun, S. Hu and M. B. Yang, Macromol.

Mater. Eng.

, 2009, 294, 336-344.

4. C. Saron and M. I. Felisberti, Mater. Sci. Eng.: A , 2004, 370, 293-301.

5. G. Dutt and K. M. Kit, J. Appl. Polym. Sci.

, 2003, 87, 1975-1983.

6. G. Q. Zheng, W. Yang, L. Huang, Z. M. Li, M. B. Yang, B. Yin, Q. Li, C. T. Liu and C. Y. Shen, J. Mater. Sci.

, 2007, 42, 7275-7285.