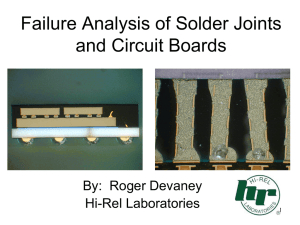

ELECTROLESS NICKEL/ ALLOY/ COMPOSITE COATINGS

advertisement