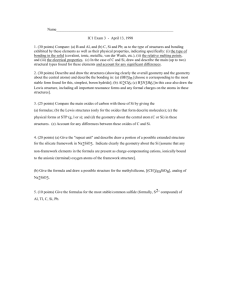

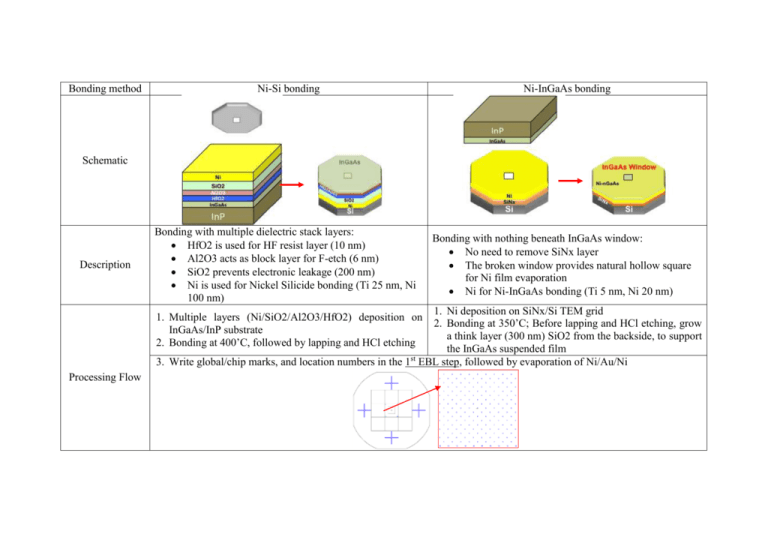

Bonding method Ni-Si bonding Ni

advertisement

Bonding method Ni-Si bonding Ni-InGaAs bonding Schematic Description Bonding with multiple dielectric stack layers: HfO2 is used for HF resist layer (10 nm) Al2O3 acts as block layer for F-etch (6 nm) SiO2 prevents electronic leakage (200 nm) Ni is used for Nickel Silicide bonding (Ti 25 nm, Ni 100 nm) Bonding with nothing beneath InGaAs window: No need to remove SiNx layer The broken window provides natural hollow square for Ni film evaporation Ni for Ni-InGaAs bonding (Ti 5 nm, Ni 20 nm) 1. Ni deposition on SiNx/Si TEM grid 2. Bonding at 350’C; Before lapping and HCl etching, grow a think layer (300 nm) SiO2 from the backside, to support the InGaAs suspended film st 3. Write global/chip marks, and location numbers in the 1 EBL step, followed by evaporation of Ni/Au/Ni 1. Multiple layers (Ni/SiO2/Al2O3/HfO2) deposition on InGaAs/InP substrate 2. Bonding at 400’C, followed by lapping and HCl etching Processing Flow 4. Write Ni Lines in the 2nd EBL step, which are used as support for InGaAs membrane as well as the source for alloy reaction. 5. Write Fin structures in the 3rd EBL step, with various orientations, both to compensate the rotation of sample alignment and to study their diffusion behaviors. Notes The multiple layers underneath InGaAs window can be This process avoids complex stacking of dialectic layers removed by HNO3 (for Ni), and F-etch (for SiO2) The post-grown SiO2 from the backside can later be HfO2 thickness has been decreased to 10nm, removed by HF dip compensated by another 6nm Al2O3 for supporting 1. I tried two method for HCl etching: 1. The window was always broken during the HCl etching: (1) The lapped sample was not released from the holding wafer during etching, and the bonded sample was previously mounted by large droplet of PMMA C2. (1) In the first attempt, I used Ti 7nm/Ni 25 nm for the bonding, which survives the lapping but not the HCl etch. Current Problems In this bonded sample, the window looks uniform, but we are not sure whether it’s flat or convex/concave. It was broken after spin The surface was rough after HCl etch, and the center seemed attacked by HCl, leaving no suspended InGaAs film. I thought the reason might be that the 25nm has fully reacted coating and 170’C bake. (2) The lapped sample was released from the holding wafer before HCl etch, and the bonded sample was previously mounted by wax. through the InGaAs layer and the Ni-InGaAs alloy was also slowly etched in HCl solution. So, I changed the thickness of metal layer to 5nm Ti/ 20nm Ni. (2) In the seconded attempt, thinner Ti/Ni was used. Longer time etch The film was unbroken, but the wrinkles can be found at the window, which might be due to the build-in stress. (from Ni-Si reaction? From introduced new Al2O3 layer?) Shorter time etch The surface become relatively smoother compared with last time, but both windows of the two samples this time are broken. Worried about the over-etch problem, so I decrease the etching time. However, even though the InP was not fully removed, the window has already broken and the edges of window seem to be attacked by etching. Any way to avoid this? Previously, I tried the patterned bonding for self-aligned S/D, some places of the unreacted area will break while others are not. There seem some changes of break the suspended film. Shall we go with TEM grids with multiple small windows?