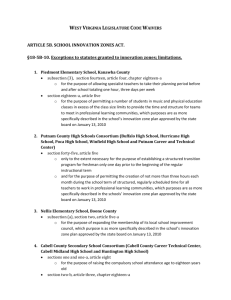

Utilisation of Carbon-Rich Waste in the Production of Clay Bricks

advertisement

Utilisation of Carbon-Rich Waste in the Production of Clay Bricks Jing Xu*, Takafumi Numata, Cathy Inglis, and Phil Morey Brickworks Building Products, 738-780 Wallgrove Road, Horsley Park, NSW 2175, Australia; *Email: jing.xu@brickworks.com.au Carbon-rich waste materials from the timber and coal industry have the potential to provide beneficial outcomes when they are added to clay bricks as an on-board fuel. Such waste materials can provide economical benefits, such as reduced energy requirements for the firing process, owing to their high calorific values and extended lifespan of the clay reserve. They also can provide environmental benefits, such as diversion of waste materials from landfill and reduced usage of non-renewable fuels. However, there are issues that must be considered when these waste materials are introduced into the clay brick manufacturing process. Firstly, adding an excessive amount of the waste material may result in bloating or deformation of the clay bricks, which occurs owing to the entrapment of gases formed by decomposition of the waste materials within the vitrified brick body during the firing process. Secondly, the presence of excess carbon in the brick body can deplete the available oxygen, leading to the reduction of red-coloured haematite (Fe2O3) in the clay to darkcoloured magnetite (Fe3O4) or wüstite (FeO). This causes an aesthetic issue in which the surface shows an undesirable non-uniform finish called hearting. To overcome these issues, optimisation of the manufacturing parameters, including particle sizes of the waste materials, rates of addition, and production speeds, is required. A balance between the benefits and the potential risks and drawbacks of introducing carbon-rich waste materials must be evaluated in order to enhance the utilisation of these materials.

![[1.1] Prehistoric Origins Work Sheet](http://s3.studylib.net/store/data/006616577_1-747248a348beda0bf6c418ebdaed3459-300x300.png)