Risk Management Overview - Northern Territory Government

advertisement

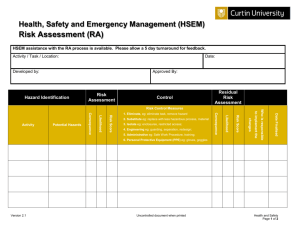

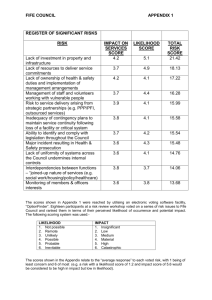

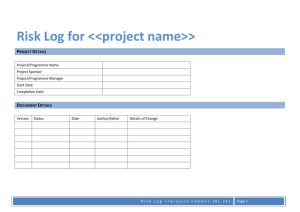

DEPARTMENT OF MINES AND ENERGY www.nt.gov.au ADVISORY NOTE RISK MANAGEMENT OVERVIEW This advisory note outlines risk management techniques to ensure the effectiveness and continuous improvement of operational risk management. OVERVIEW Risk management involves the identification, analysis and control of risks, and is essential to ensure that all reasonably foreseeable impacts on an operation have been identified and areas of opportunity are promoted. Risk management allows operators to prioritise activities so that the risks with the greatest loss and the greatest probability of occurring are handled first, and risks with lower probability of occurrence and lower loss are handled in descending order. Figure 1, derived from the Australian Standard AS/NZS 4360:2004, provides a model for continually improving risk management. Establish Context Identify the Risks Communicate and Consult Analyse the Risks Evaluate the Risks Treat the Risks Figure 1: AS/NZS4360:2004 Risk Management Overview Minerals and Energy Advisory #: AA7-021 26/11/2009 Monitor and Review Minerals and Energy Advisory #: AA7-021 26/11/2009 DEFINITIONS Table 1. Definitions adapted from AS/NZS4360:2004 Risk Management . Risk The chance of an event occurring that will have an impact on objectives. Risk Management The culture, processes and structures that are directed towards realising potential opportunities whilst managing adverse effects. Risk Analysis A systematic process to understand the nature of and to deduce the level of risk. Residual Risk The level of risk remaining after implementation of risk treatment. Event Occurrence of a particular set of circumstances. Likelihood Probability of an event occurring. Consequence Outcome or impact of an event. Frequency A measure of the number of occurrences per unit of time. Control An existing process, policy, device, practice, or other action that acts to minimise risk. Monitor To check, supervise, observe, or measure the progress of an activity or system on a regular basis, in order to identify change from the performance level required or expected. PROCEDURE 1. Establish the Context Before risks can be identified, the company’s objectives and environment in which it operates must first be considered to develop an awareness of the company’s inherent strengths and weaknesses. Threats and opportunities the company may have exposure to may also be considered. Broad considerations include: 1. Goals, including safety, environmental and business requirements. 2. Statutory and stakeholder requirements. 3. Policies, organisational structure, management systems and culture. 4. Geographic, economic and available technology considerations. From this assessment, risk control expectations and targets can be derived. Mechanisms can be chosen for controls that are appropriate to the organisation status. 2. Identify the Risks Systematic risk identification is essential to ensure all sources of exposure are considered. a. Identify and define key activities and processes Page 2 of 5 Minerals and Energy Advisory #: AA7-021 26/11/2009 The object of this step is to segment the operation into key areas that may then be studied in further detail for risks. For example, an extractive operation may break its key areas into clearing, mining, processing, product handling and storage, rehabilitation and close out to reflect the lifecycle of activity in an area. b. Identify potential issues The aim is to identify events which may affect each of the key areas identified in Step A. This can be done through identification of safety or environmental aspects from company policies, hazard identification and potential or historical incidents. c. Identify exposure pathways Once operational issues are identified, consideration should then be given to potential scenarios that may cause the event to occur. It is essential to ensure all significant pathways are detailed. One technique available for this process is to establish a matrix of event vs. possible impacts; where an activity has the potential to trigger an undesirable event a potential risk exists. These activities/impact relationships may be derived from many sources including brainstorming, checklists, scenario analysis and external reviews. 3. Analyse the Risks Once a comprehensive list of potential risks has been developed, the likelihood of that risk being triggered and the associated consequences once triggered needs to be analysed. This will help separate critical operational risk from minor acceptable risks in addition to providing an order of action based on critical exposures. When assessing the likelihood and consequences of a risk, evaluation could include: Operator knowledge and past experience. Published literature. Specialists and expert judgements. For each risk identified the likelihood of the risk occurring and the consequences of the risk exposure should be quantified using a risk matrix like the one shown in Figure 2. Page 3 of 5 Minerals and Energy Advisory #: AA7-021 26/11/2009 CONSEQUENCE Low Medium High Little to no impact Medium term -ve impact Irreversible or long term –ve impact 4 7 9 2 5 8 1 3 6 LIKELIHOOD High >75% Chance event will occur in life of plan Medium 25%<>75% Chance event will occur in life of plan Low <25% Chance event will occur in life of plan Figure 2 Risk Assessment Matrix Critical Risk High Risk Moderate Risk Low Risk Example: Uranium Exploration: drilling Likelihood: Probability of intercepting groundwater during drilling – MEDIUM Consequence: Release of radioactive water into natural drainages – MEDIUM Risk Score: 5 – Moderate Risk Tailings Dam Leak Likelihood: Probability of minor leaks occurring – MEDIUM Consequence: Contamination of groundwater, vegetation mortality – MEDIUM Risk Score: 5 – Moderate Risk Likelihood: Probability of tailings dam wall failure – LOW Consequence: Contamination of groundwater/surface water, vegetation mortality, fauna loss - HIGH Risk Score: 6 – High Risk Page 4 of 5 Minerals and Energy Advisory #: AA7-021 26/11/2009 4. Evaluate the Risks Based on the risk analysis, decisions are made about which risks need treatment and treatment priorities. The objectives of the company and the extent of opportunity that could result should be considered. 5. Treat the Risks Once the magnitude of the risks has been established, control techniques should be identified which not only reduce the risk score, but also fulfil all requirements of the context developed in step 1. Often risk control processes are a balance of cost, effectiveness and environmental requirements. Control methods should be considered in conjunction with the following hierarchy of controls, listed in order of precedence: Elimination Substitution Re-engineering Isolation Administration PPE Can the risk source be removed from the process? Can the risk source be substituted? Can the risk source be re-engineered? Can the risk source be isolated? Can the risk source be minimised administratively? (i.e. procedures and training). Can the risk source be minimised by utilising Personal Protective Equipment? PPE should only be used as a last resort, but can be used in conjunction with other controls. Whichever risk control process is utilised, it is essential facets of implementation be appropriately planned and assessed. 6. Monitor and Review To ensure risks are effectively managed, risks should be monitored and reviewed regularly (either annually, biannually or when changes or new procedures have been implemented). This ensures the risk treatment in place is appropriate for the level of risk. 7. Continual Improvement Risk management is not a static process as the environment in which operations exist is often dynamic with new control methods, stakeholder requirements and other aspects often evolving. To this end the risk process should target continual improvement with the focus being on continually attempting to minimise risk levels. For further information or advice on this subject please contact Mining Environmental Compliance Department of Mines and Energy GPO Box 4550, Darwin, Northern Territory 0801 Phone : +61 8 8999 6528 Fax : +61 8 8999 6527 E-mail : mineral.info@nt.gov.au Website : www.minerals.nt.gov.au Page 5 of 5