ch10-ClassProblems

advertisement

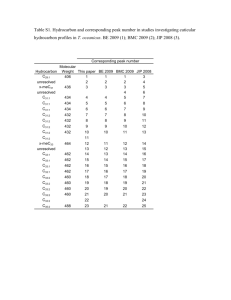

Chapter 10: Quality Control Solved problem 1, page 451 Processing new accounts at a bank is intended to average 10 minutes each. Five samples of four observations each have been taken. Use the sample data in conjunction with Table 10.2 to construct upper and lower control limits for both a mean chart and a range chart. Do the results suggest that the process is in control? Sum = Sample 1 Sample 2 Sample 3 Sample 4 Sample 5 10.2 9.9 9.8 10.1 40.0 10.3 9.8 9.9 10.4 40.4 9.7 9.9 9.9 10.1 39.6 9.9 10.3 10.1 10.5 40.8 9.8 10.2 10.3 9.7 40.0 R= Sample size n = ̿ X= = From Table 10.3, page 433: For n = A2 = D3 = Chart A2 = LCL = UCL = R Chart LCLR = UCLR = 1.2 10.5 1.0 10.30 0.8 10.10 0.6 9.90 0.4 9.70 0.2 9.50 0.0 1 D4 = #2. Problem 1, page 455 ̿ X= = Specification: Lower limit = Upper limit = a. b. Chart 2 Problem 3: An attribute control chart needs to be developed for the accuracy of meter reading using wifi meter readers. Twelve samples, each sample containing 250 readings, were checked to determine how many readings were erroneous. The results are given below. Develop a control chart that will describe 99.74 percent of the chance variation in the process. Verify whether the erroneous readings are in control. Sample No. of erroneous readings 1 15 2 12 3 19 4 2 5 19 6 4 7 24 8 7 9 10 10 17 11 15 12 3 Problem #3 0.100 0.090 0.080 0.070 0.060 0.050 0.040 0.030 0.020 0.010 0.000 1 2 3 4 5 6 3 7 8 9 10 11 12 Problem 4: There have been complaints that the sports page of a small town newspaper has lots of typos. The last 6 days have been examined carefully and the number of typos/page is recorded below. Develop a control chart that will describe 95.44 percent of the chance variation in the number of typos per page. Day Monday Tuesday Wednesday Thursday Friday Saturday Number of Typos 2 1 5 3 4 0 Problem #4 6 5 4 3 2 1 0 1 2 3 4 4 5 6 Problem 5: Run test - Solved problem #5, page 453) Sample No. of defectives 1 2 3 4 5 6 7 8 9 10 11 22 17 19 25 18 20 21 17 23 23 24 A/B U/D 5 Problem 6: The intensive care unit lab process has an average turnaround time of 26.2 minutes and a standard deviation of 1.35 minutes The nominal value for this service is 25 minutes with an upper specification limit of 30 minutes and a lower specification limit of 20 minutes The administrator of the lab wants to have four-sigma performance for her lab. a. Is the lab process capable of this level of performance? b. Modifications made to the process resulted in the average turnaround of 26.1 minutes with a standard deviation of 1.20 minutes. Is the process capable now? 6 Problem 6: a. Develop an OC curve for a sampling plan of n=40, c=1. b. If AQL is 2%, what is the producer’s risk? c. If LTPD is 9% what is the consumer’s risk? d. For an incoming lot defectives of 5%, what is the AOQ value? Let N = 1000. e. Develop a AOQ curve and determine the AOQL. Pd nPd Pa AOQ 1% 2% 3% 4% 5% 6% 7% 8% 9% 10% 7 OC Curve for n=40, c=1 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 1% 2% 3% 4% 5% 6% 7% 8% 9% 10% 4% 5% 6% 7% 8% 9% 10% AOQ Curve for n=40, c=1 2.0% 1.8% 1.6% 1.4% 1.2% 1.0% 0.8% 0.6% 0.4% 0.2% 0.0% 1% 2% 3% 8