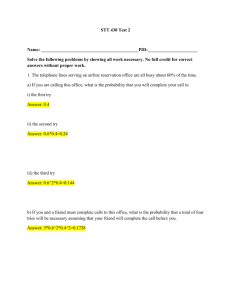

Quality Control

advertisement

QUALITY CONTROL

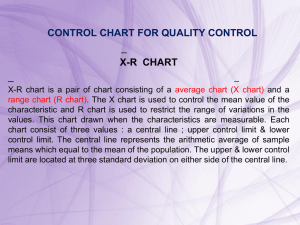

One of the common approaches to quality control is taking frequent samples during

production, inspecting them, plotting control charts to see if the production conforms to

predetermined upper and lower control limits. For example, the lower and upper limits for

diameter of a circular part may be 1.9 and 2.1 inches respectively and as long as all the parts

within these acceptable limits, the process is said to be in control.

the

the

the

are

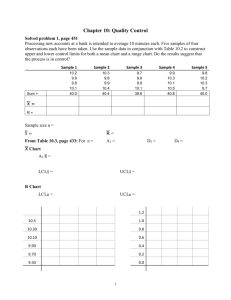

Example:

Suppose we take a subgroup every hour consisting of two measurements during a 10-hour

working day with the following results:

Subgroup

Number

Measurements

X1

X2

Subgroup

Averages

Subgroup

Ranges(R)

1

10

8

9

2

2

3

4

5

6

7

8

9

10

9

8

7

7

6

9

8

6

9

9

6

7

9

8

7

8

10

9

9

7

7

8

7

8

8

8

9

80

0

2

0

2

2

2

0

4

0

14

What are the 3-sigma control limits?

Solution:

3- control limits are given by:

X 3 x

Therefore, we first need to compute the mean of the sample means denoted by X with two bars

over it:

X 80 / 10 8

Then, we need to compute the standard deviation.

In this problem we are going to

s x

assume that the standard deviation

that is computed on the basis of the samples is

approximately equal to the true standard deviation

x

.

In real life, especially in more

sensitive quality control situations requiring precision it is essential to keep the sample size large

and exercise caution in terms of the assumptions. In reality, using

x

instead of

x

woud be

more suitable( sign on top of indicates that it is the approximate estimated value of ). Many

times, signs have not been used on the symbols that follow to keep the notation simpler).

We are going to use two different approaches in this problem. In the first approach, we

first estimate the approximate value of standard deviation as follows:

x

[(9 - 8 )2 + (9 - 8 )2 + (7 - 8 )2 + (7 - 8 )2 + (8 - 8 )2 + (7 - 8 )2 + (8 - 8 )2 + (8 - 8 )2 + (8 - 8 )2 (9 8) 2

10

x 0.775

Note: Since we don't know the true value of certain parameters and estimate them instead, some

degrees of freedom are lost; therefore, in computing x above it is wrong to divide it by 10.

However, n=10 was used in the denominator above in the estimation of x for simplicity

without getting into the complexity of degrees of freedom issue. In real life applications it is

necessary to reduce n by the degrees of freedom lost prior to using it in the denominator in the

estimation of x .

Now, we can substitute the estimated mean and standard deviation values that we computed

above into the control limits equation:

X 3

x

8 3(0.775) (5.68, 10.33)

Here, 5.68 is the lower control limit, 10.33 is the upper control limit.

As can be seen, the computations to obtain x are tedious(especially in large scale

problems). Therefore, it may be more practical to use the range concept to estimate 3 x . If the

standard deviation is not known, we can use 3x A2 R in cases where high degree of precision

is not required and where the objective is to find 3-sigma control limits( where the multiple in

front of the standard deviation is 3.) In this second approach to the computation of 3-sigma control

limits, we first compute

R = 14/10 = 1.4

Then, we can use the following equation to get the 3- limits:

X A2 R 8 188

. (14

. ) (5.37, 10.63)

Note that the results are very close to the previous lower and upper control limits. They

could have been much closer, if the example had not used unrealistic numbers like 6 inches for the

first item and 10 inches for the next item as in the case of subgroup 9. In reality, these numbers

would be quite similar like 8.06 and 8.10 for a standard product and number 6 may represent 0.06

inches above 8 and number 10 may represent 0.10 inches above 8, for example. In this problem,

simple and uncomplicated numbers were used to prevent distraction from the main procedure.

Other applications that involve lower and upper limits follow:

Example:

Given X = 2, = 0.15, n = 36 and assuming normal distribution, what percentage of sample

means would be expected to fall outside the limits of 1.925 and 2.075?

Solution:

x =

n

=

0.15

36

= 0.025

The upper limit is given by:

X z x 2 + z(0.025) = 2.075 z = (2.075 - 2) / 0.025 = 3

Probability of being below the upper limit = 0.9987

Prob. of being above the upper limit = 1-0.9987 = 0.0013

The lower limit is given by:

X z x 2 - z(0.025) = 1.925

-z = (1.925 - 2) / 0.025 = -3

Prob. of being below the lower limit = 0.0013

Note that the difference between the upper limit and the mean is 2.075 - 2 = 0.075 and the

difference between the mean and the lower limit is = 2 - 1.925 = 0.075; the differences are equal.

Therefore, this is a case with equal tails.

In reality, we could skip the computation of probability of being below the lower limit

because it would always be the same as the probability of being above the upper limit, i.e., 0.0013 in

case of equal tails; this computation has been included to provide the basic insight.

To summarize 0.0013 + 0.0013 = 0.0026 or 0.26% of the sample means would be expected

to be outside the control limits.

Example:

Specifications for a product requires that it should weigh between 11.4 and 11.8 pounds. If

the mean weight is 11.6 pounds with a standard deviation of 0.2 pounds, what percentage of the

products is expected to meet the specifications?

Solution:

= 11.6

= 0.2

P{11.4

11.8}

= P{[(11.4 - 11.6)/0.2]

= P(-

- 11.6)/0.2]}

1) -

-1) = 0.8413 - 0.1587

= 0.6826

Therefore, about 68% is expected to meet the specifications.

Example:

In a problem situation, th

sample measurements and computations shows that the mean is 3.9 and the standard deviation is

0.6.

Several more samples of size 36 are taken and each of these 36 products is measured and a sample

average (sample mean) is determined for each sample. What percent of the sample means would be

expected to fall outside the limits?

Solution:

This is a case of unequal tails; so each part should be treated separately and then combined.

imits are 4 ± 0.2 → (3.8, 4.2). The difference between the mean and the lower limit is: 3.9 - 3.8 =

0.1 and the difference between the upper limit and the mean is 4.2 - 3.9 = 0.3; as can be seen the

differences

are not equal.

x =

n

=

0.6

36

= 0.1

The upper limit is given by:

X + z

x

3.9 + z(0.1) = 4.2 z(0.1) = 0.3 z = 3

Probability of being below the upper limit = 0.9987

Prob. of being above the upper limit = 1-0.9987 = 0.0013

The lower limit is given by:

X - z

x

3.9 - z(0.1) = 3.8 - z(0.1) = - 0.1 -z = -1

Prob. of being below the lower limit = 0.1587

Therefore, 0.013 + 0.1587 = 0.16 or 16% would be expected to be outside the limits.

Control Charts for Attributes

The previous examples were related to control charts for variables such as the diameter of

circular part, the weight of a product, etc. that could be measured. On the other hand, the control

charts for attributes are used when the items are counted rather than measured such as counting the

items that are defective. In such a case we are dealing with an attribute such as defectives or

nondefectives rather than measurements of variable dimensions or weights.

The limits for the control charts for variables of our previous examples have had the form:

X z x

where X represented the average of sample means and

x

represented the standard deviation of

the sample means.

The limits for the control charts for attributes have a very similar form:

p z ̂ p

where p represents the average proportion of defective items and

p

represents estimated

standard deviation of p . The sign on indicates that it is not the true value of the standard

deviation but it is an estimated approximate value based on samples. Also, it is important to note

that it is the estimated standard deviation of p not p.

Basically, here we are talking about the average proportions or percentages rather than

average measurements such as length or weight. Here, p represents the average for proportions

whereas X represents the average for measurements; but the format is pretty much the same.

Example:

A company manufactures light bulbs in lots of 700. Inspectors take a sample of 50 from

each lot. Suppose inspectors analyzed 4 different lots by taking a sample of 50 from each lot and

found the following results:

Sample

1

2

3

4

Number of

defectives

13

16

12

11

52

Determine 95% control limits on the basis of the information above; assume that 95% control limits

imposed by management are desired and acceptable limits.

Solution:

p = 52/4(50) = 0.26

̂ = p(1 - p )/n = 0.26(1 - 0.26)/50 = 0.062

p

This is a two-tailed case because it involves both upper and lower control limits. The

standard normal table is based on one-tailed case. Assuming equal tails 95% or 0.95 has (1-0.95)/2

= 0.025 or 2.5% on each side. The conversion to one-tailed case will be 1 - 0.025 = 0.9750 or

97.5% so that we can use the one-tailed standard normal table. For 0.9750, the z = 1.96. Hence,

p z ̂ p 0.26 1.96(0.062) 0.26 0.12 (0.14,0.38)

Proportion of defectives (0.14, 0.38) can be converted to the number of defectives by multiplying by

the sample size of 50 with the result of (7,19). Hence as long as the number of defectives in each

sample is within the limits of 7 and 19, the process is said to be in control. In our example, the

number of defectives in 4 samples are 13, 16, 12, 11 and none of them is less than 7 or greater than

19, so that the process is said to be in control.

Sampling Plans

Inspecting the items that have already been produced is also a part of quality control. This

section discusses two common sampling plans.

Single Sampling

Only one sample is taken and the whole decision is based on this sample. For example,

suppose that N (lot size) = 8,000,

n (sample size) = 280, c (acceptance criterion) = 7. According to this plan, we take a sample of 280

out of 8,000. On the analysis of those 280 items, we accept the whole lot of 8,000 units if there are

7 or fewer defectives in a sample of 280 and reject the whole lot if there are more than 7 defectives.

Double Sampling

A sample is taken and analyzed. It is not conclusive, a second sample is taken. For

example, let

N = 8,000, n1 = 50, c1 = 1, r1 = 5

n2 = 140, c2 = 6, r2 = 7

According to the above plan, we take a sample of n1 = 50 and definitely accept the whole lot of

8,000 if there is 1 or fewer defectives or definitely reject it if there are 5 or more defectives. In these

cases, a second sample would not be taken.

A second sample of n2 = 140 would be taken only if there are between 1 and 5 defectives (i.e., 2, 3,

or 4 defectives) in the first sample. Then, if the cumulative number of defectives in both samples

are 6 or fewer, we accept the whole lot, if it is 7 or more defectives, we reject the whole lot. Below

are the possibilities for acceptance on the basis of cumulative number of defectives:

i)

2 defectives in the first sample plus 4 defectives or fewer in the second sample,

ii)

3 defectives in the first sample plus 3 defectives or fewer in the second sample,

iii)

4 defectives in the first sample plus 2 defectives or fewer (i.e., 0, 1, or 2 defectives) in the

second sample.

Average Outgoing Quality (AOQ)

This concept is illustrated by an example and AOQ curve and a more detailed explanation of

the concept follows the example with reference to the example and AOQ curve to provide a clearer

understanding.

Example:

A firm inspects the lots consisting of 1,000 items by taking a sample of 10 and accepts the

whole lot if there are 2 or fewer defectives. Past experience shows that the proportion of defectives

is 10%. Draw the AOQ curve.

Solution:

AOQ = p (pac) ((N-n)/N)

where

AOQ = average outgoing quality or proportion of defectives going out

p = proportion of defectives coming in

N = lot size

n = sample size

In our example, the proportion, ((N-n)/N) = ((1,000 - 10)/1,000) = .99 ≈ 1. Therefore, it is

eliminated in this example for simplicity; this proportion would be close to 1 when the lot size is

much bigger than the sample size. Now, AOQ = p (pac).

The following pac values are obtained from the binomial table with n = 10 and c(or x) = 2 for

various p values.

Proportion of

Defectives Coming In

(p)

Probability of

Acceptance

(pac)________

AOQ or

Proportion of

Defectives Going Out

[p (pac)]___________

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

1.0000

0.9885

0.9298

0.8202

0.6778

0.5256

0.3828

0.2616

0.1673

0.0996

0.0547

0.0274

0.0123

0.0000

0.0494

0.0930

0.1230

0.1356

0.1314

0.1148

0.0916

0.0669

0.0448

0.0274

0.0151

0.0074

The AOQ(proportion of defectives going out) values are simply obtained by multiplying

p(proportion of defectives coming in) values by pac(probability of acceptance) values. For example,

if an incoming lot has 10% defectives and the probability of accepting it is 92.98%, then,the

proportion of defectives going out would be expected to be 10%(92.98%) = 0.1(0.9298) = 0.0930

because only 92.98% of the lots with 10% defectives would be expected to pass the inspection.

The AOQ curve is obtained by using the numbers in the first column of the table

above(proportion of defectives coming in) as the horizontal axis values and the numbers in the third

column(AOQ or proportion of defectives going out) as the vertical axis values.

AOQ CURVE

As can be inferred from the curve, as there are more defectives in the incoming lots, there

will be more defectives in the outgoing lots. This situation is indicated by the initial upward slope

of the curve. After a certain point, as indicated by the downward slope of the curve, as the

proportion of defectives coming in increases, the proportion of defectives going out decreases. At

first, this seems contrary to our common sense; but when there are too many defectives, there is a

better chance of catching and rejecting them. Also, too many defectives would prompt tighter

inspection which would ease spotting and rejecting the bad items. When bad items are rejected,

more of the good ones

would be accepted and the proportion of defectives in outgoing lots would decrease as indicated by

the downward slope of the curve after a certain point.

Operating Characteristics (OC) Curve

Using the numbers from the p and pac column of the AOQ example we can easily construct

an OC curve.

OC CURVE

The operating characteristic (OC) curve shows the probability of accepting the lots with

various proportions of defectives. Obviously, the probability of accepting the lots with smaller

proportion of defectives is higher. For example, if the proportion defectives is 0.1, the probability

of acceptance is 0.9298 whereas if the proportion of defectives goes up to 0.3, probability of

accepting it drops to 0.3828 as can be seen from the graph.

The OC curve basically describes the ability of a sampling plan to discriminate between

high quality lots and low quality lots. A steeper OC curve would imply a more discriminating

sampling plan.