AWS FCAW Study Guide

advertisement

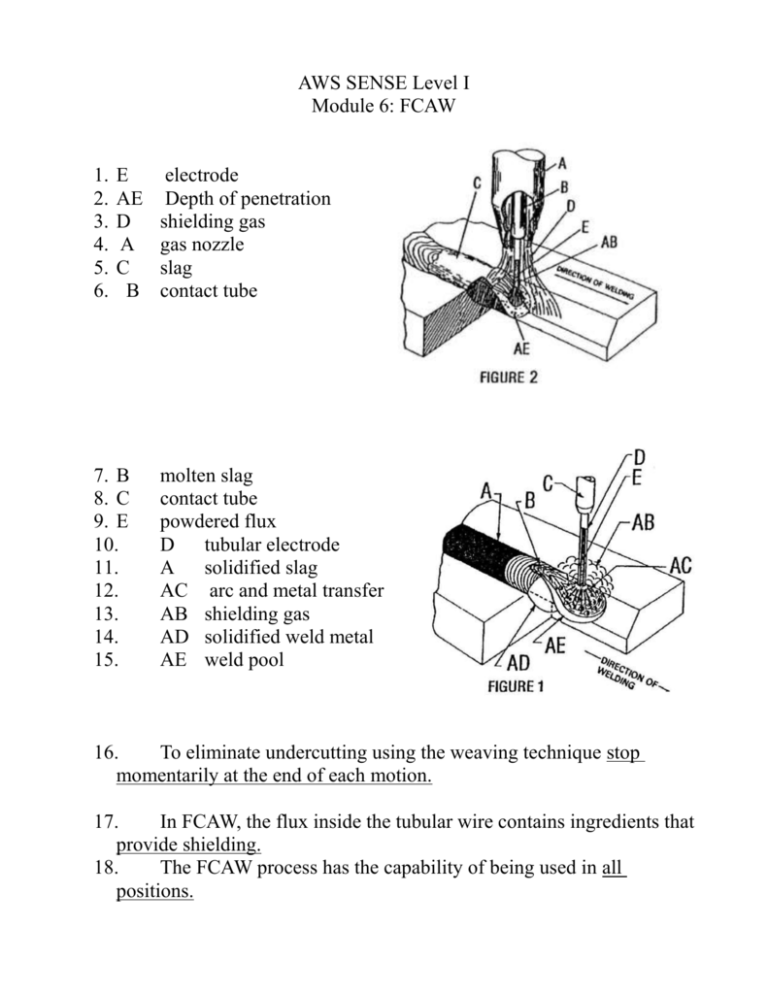

AWS SENSE Level I Module 6: FCAW 1. 2. 3. 4. 5. 6. E AE D A C B 7. B 8. C 9. E 10. 11. 12. 13. 14. 15. electrode Depth of penetration shielding gas gas nozzle slag contact tube molten slag contact tube powdered flux D tubular electrode A solidified slag AC arc and metal transfer AB shielding gas AD solidified weld metal AE weld pool 16. To eliminate undercutting using the weaving technique stop momentarily at the end of each motion. 17. In FCAW, the flux inside the tubular wire contains ingredients that provide shielding. 18. The FCAW process has the capability of being used in all positions. 19. FCAW-G indicates Gas shielded. 20. Of the two basic FCAW processes, one is self shielded, and one uses an external shielding gas. 21. A Knurled type of drive rollers should be used with FCAW electrode wires. 22. Welding in windy areas is not an advantage of the FCAW process. 23. The process does not produce slag free welds. 24. When examining a spool of FCAW wire to determine if it is designed for flux core welding, one should look for A T in the electrode classification designation. 25. A flux cored electrode used with an external shielding gas is not self shielded. 26. In the FCAW classification E71T-1 the letter T indicates tubular electrode. 27. External shielding gas is not essential for FCAW-S. 28. E71T-5 electrode classification identifies a filler metal that can be used in the overhead position. 29. A flux cored electrode that protects the weld zone from contaminates with fluxing elements released from the core of the wire itself is called self shielded. 30. In the AWS classification E71T-1, the digit after the dash designates chemical composition.