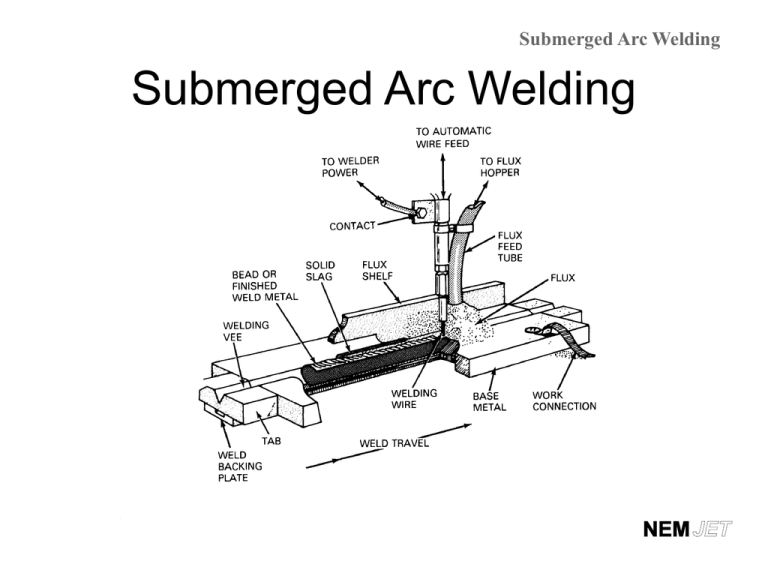

Submerged Arc Welding

advertisement

Submerged Arc Welding Submerged Arc Welding SAW Flux / Filler Metal Compositions F7A2-EM12K • F indicates flux – 70-95 ksi UTS, 58 ksi minimum yield strength, 22% elongation – A - as welded; P - postweld heat treated – 2 - minimum impact properties of 20 ft-lbs @ 20°F • E indicates electrode (EC - composite electrode) – M - medium manganese per AWS Specifications – 12 - 0.12% nominal carbon content in electrode – K - produced from a heat of aluminum killed steel Submerged Arc Welding Advantages • • • • High deposition rates No arc flash or glare Minimal smoke and fumes Flux and wire added separately - extra dimension of control • Easily automated • Joints can be prepared with narrow grooves • Can be used to weld carbon steels, low alloy steels, stainless steels, chromiummolybdenum steels, nickel base alloys Submerged Arc Welding Limitations • Flux obstructs view of joint during welding • Flux is subject to contamination porosity • Normally not suitable for thin material • Restricted to the flat position for grooves - flat and horizontal for fillets • Slag removal required • Flux handling equipment