a case study of work measurement

advertisement

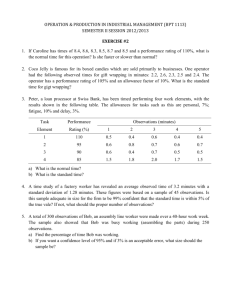

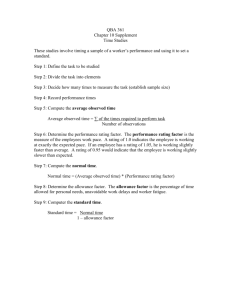

A CASE STUDY OF WORK MEASUREMENT Md. Maksudul Islam1 1 Department of Industrial Engineering and Management 1 Khulna University of Engineering & Technology Abstract— The main objective of this paper is to study the time. Actually “Work Measurement” is also called by the name “Time Study”. Work measurement is absolutely essential for both the planning and control of operations. Without measurement data, we cannot determine the capacity of facilities or it is not possible to quote delivery dates or costs. Here we were worked on a simple job for counting the required times for accomplishing the product and from that data we simply familiarized with different time study equipments to compute the standard time. Here the allowance factor and rating factor were computed to avoid minor fluctuations and to emphasize performance skill. The accuracy of time standards was depended upon the correctness of the method employed by the operators. So here we tried to avoid timing wrong methods and for this reason we chosen a representative worker with a normal pace neither too fast nor too slow. Keywords— Allowance, Normal time, Performance rating, PMTS, Standard time. . I. INTRODUCTION Time study has been defined by British Standard Institution as “The application of techniques designed to establish the time for a qualified worker to carry out a specified job at a defined level of performance”. In Predetermined Motion Time Study (PMTS), the nature of motion and conditions under which used to build up time for a job at the defined level of performance. A measuring device, stop watch is used to observe the elemental timings and usually a decimal watch is used. A decimal minute stop watch has two hands. The small hand represents minutes on dial & completes one revolution in 30 minutes. The large hand represents centi minutes (1/100 th minute) & completes one revolution in one minute and each division on large dial represents 0.01 minute. Two commonly used types of stop watches are: a) Cumulative Stop watch. b) Fly back Stoop watch. Author – Md. Maksudul Islam, Department of Industrial Engineering & Management, Khulna University of Engineering & Technology (KUET), Khulna-9203, Bangladesh. Email- maksudkhandakar@gmail.com II. METHODOLOGY Allowances: The normal time for an operation does not contain any allowances for the worker. It is impossible to work throughout the day even through the most practicable, effective method has been developed. Even under the best working method situation, the job will still demand the expenditure of human effort & some allowance must therefore be made for recovery from fatigue & for relaxation. Allowances must also be made to enable the worker to attend his personal needs. The allowances are categorized as: a) Relaxation allowance. b) Interference allowance. c) Contingency allowance. Experimental data: Individual time required for different parts (Minute) No of jobs Part 1 Part 2 Part 3 Part 4 Total Average time Rating factor Normal time, Nt Job-1 .3 6.49 3.4 1.32 11.51 3 0.5 1.5 Job-2 .25 6.5 2.12 1 10 2.5 0.5 1.25 Job-3 .2 6 2 1.3 9.5 2.4 0.5 1.2 Job-4 .4 7 2 1 10.4 2.6 0.6 1.56 Job-5 .3 5.5 1.5 1.3 8.6 2.15 0.6 1.3 Job-6 .5 4.5 1.5 1.4 8 2 0.6 1.2 Job-7 .5 4.2 1.2 1 7 1.73 0.7 1.2 Job-8 .4 3.9 1.4 1.1 7 1.75 0.6 1.05 Job-9 .3 4.1 1.1 1 6.5 1.63 0.8 1.3 Job-10 .3 3.8 1 1 6.1 1.53 0.9 1.4 Table1: Data representation for time study Now, Total cycle time = ∑ Normal time (Nt) = (1.5+1.25+1.2+1.56+1.3+1.2+1.2+1.05+1.3+1.4) = 12.96 = 13 III. DISCUSSION This experiment deals with the time study which is a work measurement technique for recording the times and rates of working for the elements of a specified job carried out under specified conditions and for analyzing the data so as to determine the time necessary for carrying out the job at the defined level of performance. Here, the rating factor was given according to the work performance and basic skills of the performers and the whole job was separated into four segments for evaluating the time consecutively. IV. CONCLUSION Time study is the recording of the time needed to do a certain amount of work in a certain way. It is tied in directly with the specific method of doing the work and is good only for that method. The use of time study permits the company to complete the picture of labor cost and also provides a fixed base so the worker will know what is expected of him during a certain period of time. REFERENCE: Martand Telsang,[1998] ‘Industrial Engineering and Production Management’, 1st Edition, S. Chand & Company ,New Delhi-110055