Direct Time Study

advertisement

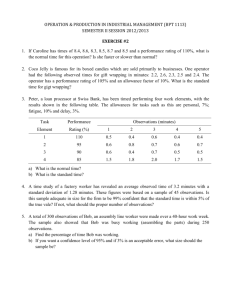

DIRECT TIME STUDY Dr. Ahmed Elyamany Time Study • Is a study of the operational steps or production procedure and the time consumed by them, for the purpose of devising methods of increasing efficiency or productivity of workers • Measures the time required to perform a task so that an output standard of production for a worker or a machine could be established. 2 Selecting the job New jobs. A change in material or method of working Worker complain about the time standard. A “bottleneck” operation Standard times are required before an incentive plan. An idle equipment. The cost of a particular job appears to be excessive. 3 Worker Approach A representative worker is one whose skill and performance is the average of the group under consideration, and who is not necessarily a qualified worker. A qualified worker is one who has acquired the skill, knowledge and other attributes to carry out the work in hand to satisfactory standards of quantity, quality and safety. 4 Steps of Time Study 1. 2. 3. 4. 5. 6. 7. Obtain and record all the job information. Break down the operation into “elements.” Determine the sample size. Record the time taken to perform each “element”. Assess the effective working speed of the operator. Extend the observed times to “basic times.” Determine the allowances to be made above the “basic time” 8. Determine the “standard time” for the operation. 5 1.Obtaining and recording information A. identification Information : Study number Sheet number/number of sheets. Name of the analyst making the study. Date of the study. Name of the person approving the study. 6 1.Obtaining and recording information B. Product Information: Name of product/part Drawing or specification number. Part number Material. Quality requirements. 7 1.Obtaining and recording information C. Process/method/plant Information: Location of the operation. Description of the operation or activity. Plant or machine. Tools. Sketch of the workplace layout. Machine speeds. 8 1.Obtaining and recording information D. Operator’s Information: Operator’s name. E. Duration of the study The start of the study (“Time on”). The finish of the study (“Time off”). Elapsed time. F. Working conditions Temperature, humidity, adequacy of the lighting, etc. 9 2.Breaking the Job An element is a distinct part of a specified job selected for convenience of observation, measurement and analysis. A work cycle is the sequence of elements which are required to perform a job or produce a unit of production. A work cycle starts at the beginning of the first element of the operation or activity and continues to the same point in a repetition of the operation or activity. 10 Detailed Elements Breakdown • To distinguish between Productive work/effective time and Unproductive activity/ineffective time. To permit the rate of working to be assessed more accurately. To allow the different types of element to be identified and distinguished. To allow elements involving a high degree of fatigue to be separated. To facilitate checking the method for error. 11 Types of Element Eight types of element are distinguished: 1. Repetitive element is an element which occurs in every work cycle of an operation. 2.Occasional element is an element which does not occur in every work cycle. 3.Constant element is an element for which the basic time remains constant whenever it is performed. Examples: switch on machine. 4.Variable element is an element for which the basic time differs in relation to some characteristics of the product. Examples: sawing wood with handsaw. 12 Types of Element 5.Manual element is an element performed by a worker. 6.Machine element is an element performed automatically by any process. 7.Governing element is an element occupying a longer time within a work cycle than any other element which is being performed concurrently. Examples: boil kettle of water while setting out teapot and cups. 8.Foreign element is an element observed which does not form a part of the operation(s) being studied. Examples: degreasing a part that has still to be machined more. 13 Rules for Breaking Down Element Elements should be easily identifiable, with definite beginnings and endings. These beginnings and endings can often be recognized by a sound. A break point is the instant at which one element in a work cycle ends and another begins. Elements should be as short as can be easily timed by a trained observer. 14 3.Sample Size • Determine the sample size or number of readings that must be made for each element, with a predetermined confidence level and accuracy margin. • The statistical method, we have first to take a number of preliminary readings (n’). We then apply the following equation for the 95.45 confidence level and a margin of error of ±5 per cent: • 15 Example • Let us suppose that we take five readings for a given element, and find that the value of the elapsed time in 1/100ths of a minute is 7, 6, 7, 7, and 6. We can then calculate the squares and the sum of the squares of these numbers: 16 3.Sample Size Number of preliminary readings (n’) < the required sample size the sample size must be increased. However, we cannot simply say that four more observations are needed. When we add the values obtained from these four additional observations, the values of x and x2 will change, and this may affect the value of n. Consequently it may be found either that a still larger sample is required, or that the sample taken was in fact adequate or more than adequate. 17 4.Timing Each Element There are two principal methods of timing with the stop-watch: Cumulative timing Fly back timing Cumulative timing has the advantage that, even if an element is missed or some occasional activity not recorded, this will have no effect on the overall time. 18 4.Timing each element • In the fly back method, errors in reading the watch may be added to the slight delay which occurs when the hand is snapped back to zero. The percentage error becomes greater for short elements. • Cumulative timing is therefore likely to be more accurate for short-element and cycle work, while fly back timing can be more safely used in jobs with long elements and cycles, since the error becomes too small to matter. 19 13.1 20 13.2 21 5.Performance Rating • Assessing the effective speed of working of the operator relative to the observer’s concept of the rate corresponding to standard rating. • Most time studies in industry are used to determine standard times for setting workloads and as a basis for incentive plans. • Rating (the assessment of a worker’s rate of working) and the allowances to be given for recovery from fatigue. 22 5.Performance Rating • A qualified worker is one who has acquired the skill, knowledge and other attributes to carry out the work in hand to satisfactory standards of quantity, quality and safety • Time studies should be made on a number of qualified workers; and that very fast or very slow workers should be avoided. • Different jobs require different human abilities. For example, some demand mental awareness, concentration, visual perception; others, physical strength; some acquired skill or special knowledge. 23 5.Performance Rating • A representative worker is defined as one whose skill and performance is the average of a group under consideration and who is not necessarily a qualified worker. • If 500 qualified workers in a given project do the same operation by the same methods and under the same conditions, the whole operation being within the control of the workers themselves, the times taken to perform the operation would be distributed in the manner shown in the table and figure below. 24 25 26 Standard rating and standard performance • The principal use of work measurement is to set time standards • Time standards can be used in planning, estimating and as a basis for incentives. • Setting standards so high will be achievable only by the best workers. • Setting standards too low will not improve worker efficiency. 27 How does the analyst obtain such a fair time from time studies? • We have already said that, studies should be taken on qualified workers to obtain a reliable average time. • It is not always possible to time a job on an average qualified worker. • People do not work consistently from day to day or even from minute to minute. • The analyst should assess the rate of the working operator and relating it to standard pace. • This process is known as Rating. 28 Rating • Rating is the assessment of the worker’s rate of working relative to the observer’s concept of the rate corresponding to standard pace. • The standard level is the average rate at which the qualified workers will naturally work at a job. • The standard rating is denoted by 100. • Standard performance is the rate of output which a qualified workers will naturally achieve without over-exertion as an average over the working day or shift. • The Standard performance is denoted as 100. 29 How the rating factor is used • It is usual practice to round off ratings to the nearest multiple of five on the scale. • If the rate is judged to be 13% above standard, the rate is 115. • If the study person’s ratings were always perfect, the results should be: Observed time x rating = a constant 30 6.Basic Time • The basic time represents the time taken by the operator to perform an element if the operator were working at the standard rate. • If the operator was working slower than the standard, basic time is < observed time. • If the operator was working faster than the standard, basic time is > observed time. 31 6.Basic Time 32 6.Basic time • The most common method of selecting the representative basic time is calculating the average of the estimated basic times. 33 Example • During a time study made on the operation of inspecting and covering a book, one element was described as: “Pick up one book, inspect, initial at end of paper (break point: book closed)”. • This element was observed 31 times, and the basic minutes calculated (in 1/100 min) were as follows: • 34 Example • Exclude the basic time of 0.49 minutes because of a faulty operation. • The total of the remaining 30 basic times is 7.97 minutes. • The average basic time is 0.266 minutes per occasion. 35 Example • At the end of the calculations, the basic time finally selected would be rounded off to the nearest two figures, in this case 0.27 minutes. • The excess work observed (0.49 - 0.27 = 0.22) would be carried down to the contingencies record. 36 Work content • The work content of a job or operation is defined as : • Basic time + relaxation allowance + contingency allowance 37 38 7.Allowances • Many jobs require spending of human effort, and some allowance must therefore be made for recovery from fatigue and for relaxation. • Allowance must be made to allow a worker to attend to personal needs. 39 7.Allowances • Relaxation allowances are intended to assist recovery from fatigue. • Relaxation allowances are the only essential part of the time added to the basic time. • Other allowances, such as contingency, policy and special allowances are applied under certain conditions only. • Contingency allowances may also have to be added to the basic time in order to give the work content. 40 Apply Allowances • A PFD (personal time, fatigue, and delays) allowance is added to the basic time to compute the standard time Tstd = Tb(1 + Apfd) where Apfd = allowance factor for personal time, fatigue, and delays • The function of the allowance factor is to inflate the value of standard time in order to account for the various reasons why the worker loses time during the shift 41 8.Standard time • Standard time is the total time in which a job should be completed at standard performance. • The contingencies and relaxation allowances are percentages of the basic time. • The standard time is expressed in standard minutes or standard hours. 42 Example A direct time study was taken on a manual work element. The regular cycle consisted of three elements, a, b, and c. Element d is an irregular element performed every five cycles. Work element a b c d Observed time (min) 0.56 0.25 0.50 1.10 Performance rating 100% 80% 110% 100% Determine: (a)Basic time (b)Standard time for the cycle, using allowance factor of 15%. 43 Solution (a) Basic time: Tb = 0.56(1.00) + 0.25(0.80) + 0.50(1.0) + 1.10(1.0)/5 = 1.53 min (b) Standard time: Tstd = 1.53(1 + 0.15) = 1.76 min 44 Machine Cycle in the Task • If the work cycle includes machine-paced elements, then standard time may include a machine allowance applied to the machine time Tstd = Tbw(1 + Apfd) + Tm(1 + Am) where Tbw = basic time for worker (external) elements, Tm = machine cycle time (assumed constant), and Am = machine allowance 45 Example • An example of a time study - extracts from the two main documents in time study follow: Element number Rating Observed time (1/100 min) Basic time (1/100 min) 1 90 30 27.0 2 80 95 76.0 3 80 45 36.0 4 90 10 9.0 5 75 22 16.5 6 80 17 13.6 1 80 33 26.4 3 75 46 34.5 4 75 10 7.5 (etc.) (etc. etc..) 46 Example • Time study analysis sheet Element number Basic time Relaxation Basic time Allowance% X Frequency Standard time (min) Basic time (1/100 min) Frequency 1 29 1/1 0.290 10 0.319 2 75 1/8 0.094 10 0.103 3 38 1/1 0.380 10 0.418 4 9 1/1 0.090 10 0.099 5 15 1/1 0.150 10 0.165 6 17 1/1 0.170 15 0.196 7 96 1/12 0.080 18 0.094 Standard cycle time (min) = • Cycles in one hour = 60 / 1.394 = 43 cycle/hour 1.394 47 Contact: Dr. Ahmed Elyamany 019-4100-824 a2hyamany@yahoo.com QUESTIONS 48