industrial management

advertisement

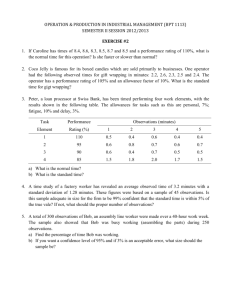

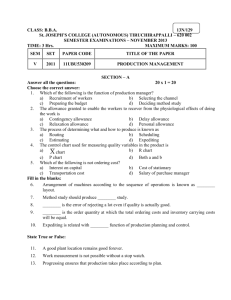

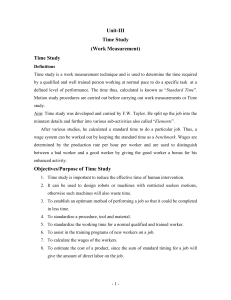

INDUSTRIAL MANAGEMENT BY: MAYANK PANDEY ASSISTANT PROFESSOR NIET BUSINESS SHOOL 14-03-2014 00:43:54 UNIT-2 • Management Function: Principles of Management. • Management Tools: time and motion study, work simplification- process charts and flow diagrams, Production Planning, Specification of Production requirements. 14-03-2014 00:44:00 Fayol’s General Principles of Management 1. 2. 3. 4. 5. 6. Division of Work Authority Discipline Unity of command Unity of direction Subordination of individual interest to general interest 7. Remuneration 8. Centralization 9. Scalar chain 10. Order 11. Equity 12. Stability of personnel tenure 13. Initiative 14. Esprit de corps 14-03-2014 00:44:00 Production Planning and Control • Production planning and control can facilitate the small entrepreneur in the following ways. Optimum Utilization of Capacity Inventory control Economy in production time Ensure quality 14-03-2014 00:44:00 Steps of Production Planning and Control Production Planning and Control Production Planning 14-03-2014 00:44:00 Production Control Planning Dispatching Routing Following up Scheduling Inspection Loading Corrective Measures • Aggregate Planning: The objective of aggregate planning is to find out the most economical method of using production resources to meet fluctuating demands of production output • Routing: Routing procedure involves following different activities. 1. The operations to be carried out on a job. 2. The machine or work centre to be used. 3. The details of operations to be performed. 4. The sequence of operations from raw material to finished product. 14-03-2014 00:44:00 • Scheduling: Working out of time that should be required to perform each operation and also the time necessary to perform the entire series as routed, making allowances for all factors concerned. – Master Schedule: Scheduling usually starts with preparation of master schedule which is weekly or monthly break-down of the production requirement for each product for a definite time period. – Production schedule: It takes into account following factors. • 1. Physical plant facilities • 2. Personnel who possess the desired skills and experience • 3. Necessary materials and purchased parts. • Loading: Loading determines who will do the work as routing determines where and scheduling determines when it shall be done. 14-03-2014 00:44:00 Production Control Dispatching: Dispatching involves issue of production orders for starting the operations. Necessary authority and conformation is given for: 1. Movement of materials to different workstations. 2. Movement of tools and fixtures necessary for each operation. 3. Beginning of work on each operation. 4.Recording of time and cost involved in each operation. 5. Movement of work from one operation to another in accordance with the route sheet. 6. Inspecting or supervision of work. 14-03-2014 00:44:00 • Follow up: All problems or deviations are investigated and remedial measures are undertaken to ensure the completion of work by the planned date. • Inspection: This is mainly to ensure the quality of goods. It can be required as effective agency of production control. • Corrective measures: Corrective action may involve any of those activities of adjusting the route, rescheduling of work changing the workloads, repairs and maintenance of machinery or equipment. 14-03-2014 00:44:00 SPECIFICATION OF PRODUCTION REQUIREMENT 1. Part Drawing (Production Drawing) 2. Machining Detailed and Sequences 3. Materials & components 4. Quality level required 5. Production Quantity 14-03-2014 00:44:00 WORK STUDY • Work Study implies the study of human work. Work study investigates the work done in organization and it aims at finding the best and most efficient way of using available resources men, material, machine and money. 14-03-2014 00:44:00 Work Study & Productivity WORK STUDY METHOD STUDY WORK MEASUREMENT Choose & evaluate one best standard Method Choose and evaluate one best standard time Standard Time & Standard Method 14-03-2014 00:44:00 Rise in Productivity Objectives of Work Study Improved working process and standardized. Less fatigue to the operator. Efficient utilization of men material. To evaluate human work. To reduce ineffective time due to management & workers. 14-03-2014 00:44:00 Benefits of Work Study Improved Productivity. Higher efficiency in productivity. Manufacturing cost is reduced. Quicker and accurate delivery dates. Good employeeemployer relationship. Job satisfaction to workers. Higher wages and incentives to workers. 14-03-2014 00:44:00 Method Study or (Motion Study) • Method study is systematic recording and critical examination of existing and proposed ways of doing work, as a means of developing and applying easier and more effective methods and reducing costs. 14-03-2014 00:44:00 Objectives of Method Study The improvement of process and procedures. The improvement of factory, shop and workplace layout and of the design of plant and equipment. Economy in human efforts and reduction of unnecessary fatigue. Improvement in use of materials, machines & manpower To find out the best way of doing a job. To standardize the best method. Effective material handling 14-03-2014 00:44:00 Various Considerations Economic Consideration Technical Consideration 1. Operation involving great deal of manpower condition 1.Bottlenecks holding production 2. Highly fatigued work 2. Movement of material 2. Reduce the efforts and over long distances fatigue of workers between shops 3. Operations involving repetitive work 3. Inconsistency in quality 14-03-2014 00:44:00 Human Reactions 1. More acceptable if it can Improve working Method Study Select the subject to be studied Record facts relating to existing method Diagram Charts Model Examine all relevant facts critically Purpose Place Sequence Develop alternative to existing methods Install the new method Plan-arrange-implement Maintain new method Verify its implications at regular intervals 14-03-2014 00:44:00 Higher Productivity Person Means Work Measurement • Work measurement is concerned with elimination of ineffective time and establishment of time standards for a job. • “Work measurement is a technique to establish the time for a qualified worker to carryout a specified job at a definite level of performance.” 14-03-2014 00:44:00 Uses of Work Measurement 1. To reveal the existence of ineffective time. 2. To compare the efficiency of alternative method. 3. To determine with the help of man machine chart the number of machine an operator can run. 4. To set the time standard for carrying out the work. 5. As a basis for realistic and fair incentive scheme. 14-03-2014 00:44:00 Time Study • Time study is a work measurement technique for recording the times performing a certain specific job or its elements carried out under specified conditions, and for analyzing the data so as to obtain the time necessary for an operator to carry it out at a defined rate of performance. 14-03-2014 00:44:00 Time Study Equipments 1. Stop Watch A fly back decimal- minute stopwatch is most commonly used stop watch. 2. The Study Board Time study board is flat board , of plywood or plastic sheet, having fittings to hold stop watch and time study forms. 3. Time Study Forms Time study forms are printed forms of standard size constant information like product name, operation number, description of operation, time study observer’s name etc are preprinted on the top of the sheet14-03-2014 00:44:00 Time Study Form Time Study Form Product-------Operation No----------Description of Operation -------------------No. of Cycles 5(say) Standard time found------ Element Description Observed time 1 14-03-2014 00:44:01 Time Study ------------Observer Date------------------- 2 3 4 Average observed Time 5 Rating factor Normal Time All Std. Time Procedure for Collecting Time Study Data • 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. The following are the procedural steps in stop Watch time study:Identify the operation to be studied Obtain the improved procedure from method study departments. Collect and check necessary equipment Select the worker to be observed for Time Study Explain the worker the objective of Time Study Explain the worker the improved procedure. Break the operation into small elements. Determine the number of observations to be timed for each element. Conduct the observation and record them on time study form Rate also the performance of the worker during step. Calculate normal time from observed time by using performance rating factor Observed time X Rating factor Normal time=________________________________ 100 13. Add process allowance, rest and personal allowance and special allowances to normal time in order to obtain standard time. 14-03-2014 00:44:01 Conversion of observed Time to Standard Time Observed Time Apply Performance Rating Factor Normal Time Add allowances like personal allowance, process allowance Standard Time 14-03-2014 00:44:01 Advantages of Time Study 1. Standard labour cost per unit of product can be calculated. 2. Comparisons of actual and standard production. 3. Enable further improvement in work methods, training necessity and better workplace layout. 14-03-2014 00:44:01 Limitations of Time Study 1. Not suitable for non- repetitive jobs. 2. Not suitable for highly automated work place 3.May affect operator’s morale if output standard is not attained. 4. While rating a worker error may come due to subjectivity involved in it. 14-03-2014 00:44:01 Feel Free to ask your queries on mayankkumarpandey@gmail.com 14-03-2014 00:44:01