010815173434ModifiedabstractSusChemE2015

advertisement

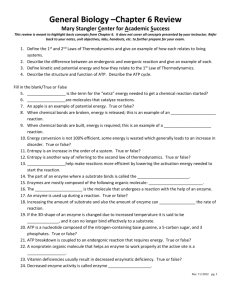

SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai Utilization of high endocellulytic potential of enzymes for effective cellulose saccharification 1 Chinmayee R. Mahadik , Annamma A. Odaneth1, Arvind M. Lali1 1 DBT-ICT CEB, Institute of Chemical Technology, Matunga, Mumbai-400019 E-mail addresses: chinmayee.mahadik@gmail.com, aannamma@gmail.com, arvindmlali@gmail.com 1. Introduction: Rapid depletion of fossil fuel energy sources has led research towards exploration of second generation biofuels derived from Lignocellulosic biomass (LBM) using biorefining methods. Lignocellulosic biomass (LBM) is enzymatically hydrolyzed to obtain monosugars which are subsequently fermented to produce bioethanol [1]. Enzymatic transformations performed using commercial cellulases having definite ratio of three major enzyme namely Cellobiohydrolases, Endoglucanases and glucosidases. However, high costs and dosage of these commercial cellulase concoctions have been significant barriers for commercialization. Proper balance of enzyme cost and individual activity of powerful stable enzymes mark the strides for saccharification and can help in development of a new sustainable technology [2,3]. Thus the current study aims at improvising the two-step process of saccharification by utilizing enzymes and combinations thereof, to increase stability of cellulases used and thereby effect the overall cost contribution of enzymes in the saccharification step. 2. Material and Methods: Two cellulase preparations (Enzyme A and Enzyme B) were procured from different enzyme manufacturers, respectively . Specific activities of Cellobiohydrolases, Endoglucanases and -glucosidases were calculated in terms of FPU, CMC and CBU as described by Ghose et.al. (1987). Reaction parameters: Pretreated rice straw biomass (1%) was hydrolysed using 100FPU/g of cellulose for 12 hours at 50C in 50mM citrate buffer pH 4.8. The monosugar released were analyzed on 87H Aminex column using 5mM sulphuric acid at 0.6ml/Min flow rate. Solubilization of biomass was monitored by gravimetric methods. 3. Significant Results and Discussion 3.1 Specific enzyme activities indicate higher endocellulolytic potential of enzyme B than that of enzyme A. Enzyme A displayed better hydrolysis of lignocellulosic biomass. However, comparatively lower endocellulase activity of enzyme A did not influence the effective saccharification of the cellulose due to the high beta glucosidase activity. High solubilization due to high endocellulase activity is exhibited in saccharification by Enzyme B. Poor saccharification of the biomass was observed due to very low beta glucosidase activity. This necessitates the use of specific beta glucosidase to achieve maximum hydrolysis by breaking down of oligosaccharides formed by the high endocellulase activity. We hereby propose an improved model of two step enzymatic saccharification . 1 SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai Table 1: Effect of endocellulase and β-glucosidase activity on efficient saccharification of biomass Activity Enzyme Hydrolysis (%) Solubilization (%) CMC/mL CBU/mL A 353 2.7 82 86 B 624 105 61 95 3.2 Commercial enzymes are expensive due to their very high activity but the low recyclability , thus utilization of economical enzyme combinations for a lower time period and multifold use can provide a better option to the existent technologies of saccharification. Existing process: Single enzymatic treatment --- Pretreated Biomass Monosugars Long reaction time, low recyclability Proposed Process: High CMC units Pretreated Biomass Maximum solubilization More oligosaccharides High CB units Monosugars Very low reaction time Very low enzyme dosage Low reaction time 4. Conclusions: Competent biorefinering processes impose the use of low cost, highly specific enzymatic systems for efficient saccharification. Therefore, strategies aimed at reducing enzyme dosage for the overall saccharification step carries immense value as enzymes are highly expensive. To meet the challenges in this area, use of minimal enzyme combinations are the need of the moment. Our work is an important step in this direction and would aid in a huge reduction in the overall cost of the saccharification process, ensuring sustainability of the enzyme mediated hydrolysis of Lignocellulosic Biomass (LBM) 6 based cellulose to pure glucose. References [1] Xiaoxiao Yu et.al. ,Pak. J. Pharm. Sci., 28:3 2015, 1115-1120. [2] Tetsushi Kawai et.al., J Ind Microbiol Biotechnol, 2012 39 ,1741–1749. [3] Rani, et al., J Bioproces Biotech 2014, 5:1, 1-8. 2