Module 8 Summative 8.1 MODEL ANSWER

advertisement

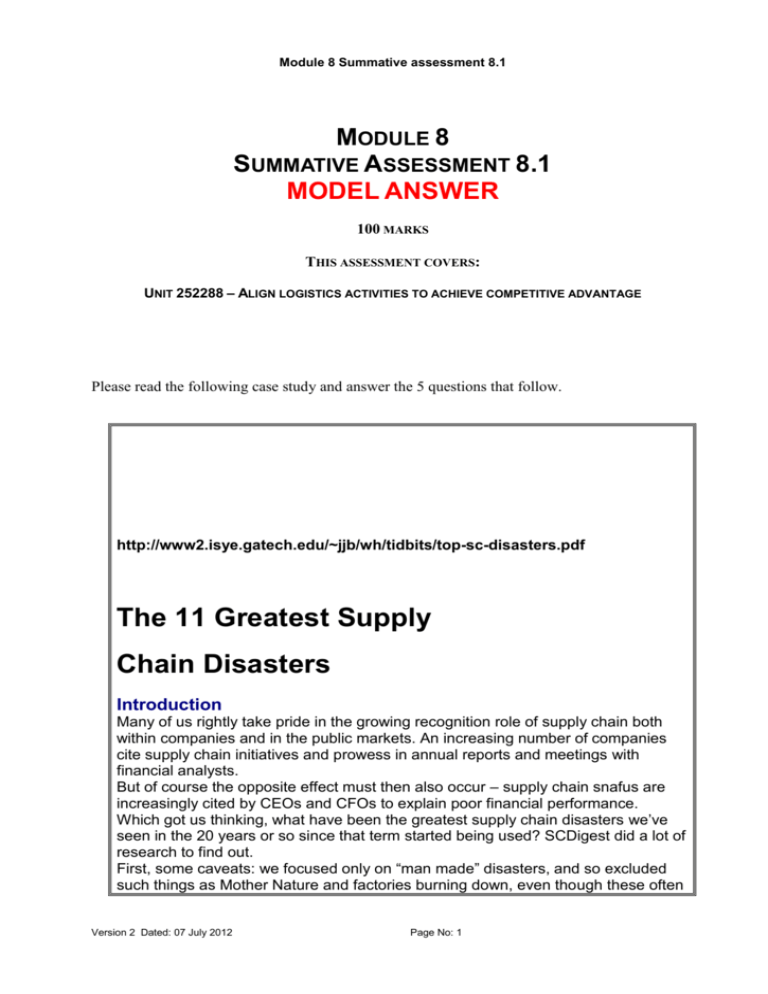

Module 8 Summative assessment 8.1 MODULE 8 SUMMATIVE ASSESSMENT 8.1 MODEL ANSWER 100 MARKS THIS ASSESSMENT COVERS: UNIT 252288 – ALIGN LOGISTICS ACTIVITIES TO ACHIEVE COMPETITIVE ADVANTAGE Please read the following case study and answer the 5 questions that follow. Januahttp://www2.isye.gatech.edu/~jjb/wh/tidbits/top-sc-disasters.pdfry 2006January 2006 http://www2.isye.gatech.edu/~jjb/wh/tidbits/top-sc-disasters.pdf The 11 Greatest Supply Chain Disasters Introduction Many of us rightly take pride in the growing recognition role of supply chain both within companies and in the public markets. An increasing number of companies cite supply chain initiatives and prowess in annual reports and meetings with financial analysts. But of course the opposite effect must then also occur – supply chain snafus are increasingly cited by CEOs and CFOs to explain poor financial performance. Which got us thinking, what have been the greatest supply chain disasters we’ve seen in the 20 years or so since that term started being used? SCDigest did a lot of research to find out. First, some caveats: we focused only on “man made” disasters, and so excluded such things as Mother Nature and factories burning down, even though these often Version 2 Dated: 07 July 2012 Page No: 1 Module 8 Summative assessment 8.1 evidence holes in supply chain strategy and risk reduction plans. Second, we looked for examples that had a significant impact on the company in terms of finances, stock price, brand equity, etc. Third, it’s still subjective, and we probably missed a few “good” candidates. Below you will find a summary table of our “Top 11,” ( weird number, yes, but we just couldn’t find one to cut) in order from worst to not quite as worse, as well as more detailed stories of the nature and impact of each disaster. Interestingly, none of our Top 11 occurred after 2001. Coincidence? While at one level we see more public attention to supply chain issues, it appears the lessons from failures 6. Toys R Us.com Christmas 1999 It’s 1999, and on-line retailing is finally starting to heat up. The on-line division of the leading toy retailer, Toys R Us, advertises heavily, and promises it will make Christmas deliveries for any orders placed by Dec. 10. Toys R Us.com is swamped with tens of thousands of orders. Though the inventory is mostly in place, the company simply cannot pick, pack and ship the orders fast enough – though it was close. “We’d have been OK if Christmas was on Dec. 26,” one company executive says. Some employees work 49 straight days Just a couple of days before Christmas, the company sends out thousands of now infamous “We’re sorry,” emails, telling those customers their orders will not arrive in time for Christmas. The media has a field day, and customers are irate. “How do I explain to my four-year-old that his present will be coming a week late?” is typical of more gentle complaints in the avalanche of mail and calls the company receives. “I’ve never been exposed to fouler language,” says then vice president Joel Anderson. The Toys R Us brand generally takes a big hit, even though other e-tailers have some similar problems. In fact, the Christmas of 1999 causes hundreds of companies to analyze their e-fulfillment capabilities in more detail the following year, and put in capabilities that significantly reduce the issues in 2000 and beyond. The Toys R Us.com failure really was a wake up call to the rest of the industry. Toys R Us.com later outsources its fulfillment to Amazon.com. About SupplyChainDigest SupplyChainDigest™ is the industry’s premier interactive knowledge source, providing timely, relevant, in-context information. Reaching tens of thousands of supply chain and logistics decision-makers each week, our flagship publications SupplyChainDigest and SupplyChainDigest – Logistics Edition, and web site (www.scdigest.com) deliver news, opinions and information to help end users improve supply chain processes and find technology solutions. Subscribe today – it’s free. Version 2 Dated: 07 July 2012 Page No: 2 Module 8 Summative assessment 8.1 For more information, contact SupplyChainDigest at: PO Box 714 Springboro, OH 45066 937-885-3253 www.scdigest.com email: info@scdigest.com Please answer the following 5 questions: 1. How would you implement supply chain strategies with specific reference to the article above? (20 marks) 2. How would you optimising supply chain functions with specific reference to the case study above? (20 marks) 3. Explain how you would measure the supply chain operation with specific reference to the case study above? (20 marks) 4. Explain how you would enable supply chain operations with technology with specific reference to the case study above. (20 marks) 5. Explain how you would maximise returns on supply chain investments with specific reference to the case study above. (20 marks) ********************************************************************************* MODEL ANSWER The weighting of the marks must be 50/50 where the assessor determines where the key knowledge criteria have been expressed and described within the responses to equal approx 50% of the marks, and thereafter award the balance of 50% of the marks to the application of that knowledge by virtue of analyses, comparison, critique, or any other. The Blooms taxonomy rose may be utilised to identify the appropriate verb for the application of knowledge. Q1. The student must identify elements of the organisation's supply chain for the purpose of integrating them The student must create conditions for collaboration between all parties by defining the nature of the relationship between the strategic partners and players Version 2 Dated: 07 July 2012 Page No: 3 Module 8 Summative assessment 8.1 The student must create a demand network by aligning key organisational functions to customers demand The student must incorporate agility, flexibility and responsiveness into the supply chain to prevent loss of sales The student must incorporate supply chain forecasting and visibility into the organisation's information systems by the use of collaborative information sharing and enhanced accessibility The student must apply supply chain auditing, modelling and planning through the use of analytical tools, management exercises and management team integration The student must manage relationships with supply chain providers through the allocation of resources (resources may include but are not limited to in-house, partnership, co-source, outsource to fourth party logistics provider, subcontract to third party logistics provider) Q2. The student The student must build distribution networks in order to satisfy cost and service level criteria The student must structure inbound logistics systems in order to meet the requirements of the demand network The student must develop freight forwarding solutions to integrate with the international procurement requirements of the organisation The student must apply optimisation tools to manage the organisations inventory The student must execute a logistics management strategy which integrates upstream and downstream operations The student must implement strategic sourcing and procurement strategies with strategic suppliers of goods and services The student must implement an integrated transport for maximum up and downstream integration at least cost in use of final product The student must integrate warehousing operations with the overall supply chain Q3. The student must conduct a supply chain audit to identify areas for continuous improvement (reference models may include but is not restricted to Stock and Lambert, Porter and integrated framework model) The student must source best practices used by local and international companies within an organisation's field in order to assist implementation of the organisations best practice The student must carry out a structured, measurement driven process to continually monitor and improve supply chain performance Version 2 Dated: 07 July 2012 Page No: 4 Module 8 Summative assessment 8.1 Q4. The student must integrate information systems across the supply chain to follow for maximum visibility by all functions The student must organise the information system of the organisation to achieve maximum integration between key supply chain elements (supply chain elements may include but are not restricted to key products, key customers and key processes) The student must integrate operational Information Communication Technology (ICT) systems to provide and optimise supply chain integration [operational ICT systems may include, but is not limited to Enterprise Resource Planning (ERP), Systems Application Programme (SAP), Materials Requirement Planning (MRP), Electronic Data Interchange (EDI)] Q5. The student must mapped, audit and benchmark the supply chain of the organisation benchmarked in order to monitor costs The student must review fixed assets in order to achieve maximum agility and responsiveness to the needs of the demand network The student must identify risk elements in the supply chain in order to manage them Version 2 Dated: 07 July 2012 Page No: 5