3b Grand Junction USMS SWMP 10.23.12

advertisement

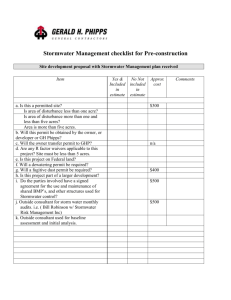

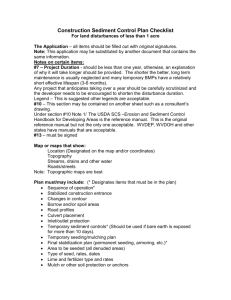

USMS STORMWATER MANAGEMENT PLAN Canyon View Medical Plaza G Rd & 23 ¾ Rd Grand Junction, CO Project Manager and Site Operator: GH Phipps Construction Companies 5995 Greenwood Plaza Blvd., Suite 100 Greenwood Village, CO 80111 SWMP Contact(s): Name: Brady McQuinn Title: Project Engineer Phone: (303) 356-3999 Preparation Date: Original Date: 10/23/12 Estimated Project Dates: Start Date: November 12th, 2012 Completion Date: January 30th, 2014 CDPHE project or permit tracking number: ____________________ 1 Section: Page # 1.0 SITE DESCRIPTION a) Description/Nature of Construction Activities b) The Proposed Sequence of Major Activities c) Total Site & Disturbed Area d) Site/Soils Data e) Existing Vegetation f) Location/Description of Potential Pollution Sources g) Non-Stormwater Discharges h) Receiving Waters 3 3 3 4 4 4 4 4 5 2.0 SITE MAP(s) 5 3.0 STORMWATER MANAGEMENT CONTROLS a) SWMP Administrator b) Phased BMP Implementation Table 1.1 Table 1.2 Table 1.3 Table 1.4 Table 1.5 c) Identification and Evaluation of Potential Pollutant Sources Table 2.0 d) Best Management Practices (BMPs) for Stormwater Pollution Prevention 1) Structural Practices 2) Non-Structural Practices Table 3.0 3) Materials Handling & Spill Prevention 4) Dedicated Concrete/Asphalt Batch Plants 5) Vehicle Tracking Control 6) Waste Management/Disposal 7) Groundwater & Stormwater Dewatering 5 5 6 6 6 7 7 8 8 8 9 9 9 9 10 13 13 13 13 4.0 FINAL STABILIZATION 13 5.0 USMS INSPECTION PROCEDURES AND SITE MAINTENANCE 13 6.0 SWMP CERTIFICATION 15 Appendix 1 16 - Pre-existing vegetation photos 2 INTRODUCTION This storm water management plan (SWMP) has been prepared for the Canyon View Medical Plaza. The goal of the SWMP is to identify potential pollutant sources to stormwater, and identify Best Management Practices (BMPs) that, when implemented, will reduce or eliminate negative impacts to water quality. Where it is necessary, this SWMP will be coordinated with other environmental permits obtained by the project. 1.0 SITE DESCRIPTION a) Description/Nature of Construction Activities. The project involves the construction of a medical office facility with associated parking lots, utilities, and landscaping. b) The proposed sequence of major activities. Construction for all work associated with the project will begin on or about November 12th, 2012 with project completion around January 30th, 2014. The project will be completed in 5 Phases as described below: Phase 1 – Mobilization 1) Prep Staging Area, Install Perimeter Fence & Install Initial BMPs 2) Mobilize Trailers and Equipment. Phase 2 – Clear & Grub, Excavation 1) Clear & Grub / Overlot Grading 2) Over-excavation / Structural Fill 2) Foundation Excavation Phase 3 – Underground Utilities 1) Install Underground Utilities Phase 4– Vertical Construction & Impervious Surfaces 1) Drill/Pour Piers, Foundation Walls, SOG 2) Backfill Walls 3) Install Steel Structure 4) Roofing & Roof Drains 5) Exterior Masonry 6) Interior Finishes 7) Install Curb/Gutter & Sidewalks 8) Grade/Prep & Pave Parking Lots Phase 5 – Final Grading & Stabilization 1) Finish Grading 2) Install Irrigation System 3) Install Plants/Sod/Permanent Seeding/Mulch 3 c) Estimates of the total area of the site, and the area and location expected to be disturbed by clearing, excavation, grading, or other construction activities. The project is located at G rd & 23 ¾ rd in Grand Junction, CO. Latitude: 39 06 25N Longitude: 108 36 35W The total area of the project will encompass 7.2 acres, with a total of 7.2 acres of disturbed area. d) A summary of any existing data used in the development of the site construction plans or SWMP that describe the soil or existing potential for soil erosion. According to the NRCS web site, the upper layers of soils at the project site are sager silty clay loam and turley clay loam. These soils have a whole soil K factor of .32 and .20. According to these K values, the soil at this site is mildly to moderately erosive. – per sheet C2.3 of the construction drawings done by Boulder & Associates 8/7/12. e) A description of the existing vegetation at the site and an estimate of the percent vegetative ground cover. The existing vegetation on the project consists primarily of high desert vegetation (sage, rabbit brush, etc) with an approximate density of 50% over the project. – per sheet C2.3 of the construction drawings done by Boulder & Associates 8/7/12. f) The location and description of all potential pollution sources. Refer to Table 2.0 g) The location and description of any anticipated allowable sources of non-stormwater discharge at the site. Stormwater or groundwater de-watering is not expected to occur during the construction process; however any groundwater encountered will not be allowed to mix with surface waters but will be allowed to infiltrate back into the soils. Any necessary stormwater dewatering will remain on-site and will be land applied. The following allowable non-storm water discharges are likely to be present on this project: Fire Hydrant Flushing Fire hydrant flushing may be required at the direction of the local fire officials. The volume and velocity of water released during flushing operations can be very destructive if not adequately controlled. When fire hydrant flushing is required, the discharge will be directed onto nonerodible surfaces such as asphalt or concrete paving and into the piped storm drain system. Potable Water Line Flushing Potable water line flushing will be discharged in a manner that prevents erosion of soils on the site. Potable water may be discharge onto stabilized surfaces or into sanitary drains if allowed by local authorities. 4 Routine External Building Wash Down Without Additives The use of water without additives to wash down building exteriors is allowed but must be contained and allowed to evaporate or infiltrate the soils. Wash water will not be allowed to cause noticeable erosion of soils Uncontaminated Excavation Dewatering When dewatering of excavations is required it will be done in a manner that does not contribute additional pollutants to storm water discharges. Suction ends of pump hoses will be protected to minimize the potential to draw additional sediment into the water stream. Discharge ends of pump hoses will be affixed with an energy dissipation and sediment containment device. Pump discharge must not cause visible erosion to exposed soils. Discharge will be land-applied as described above, or into a settling or infiltration structure whenever possible to minimize turbidity. Groundwater will not be discharged from the project without a separate Dewatering Permit. Landscape Irrigation Newly installed sprinkler systems will be tested when crews are available and before the pipes are buried so that visual inspections of the system can be performed prior to covering the pipes. Any repairs will be made promptly to prevent erosion of disturbed soils. Concrete Washout Waste Refer to Section 3.b. of SWMP binder #2 h) Receiving Waters Runoff from the site will enter the City of Grand Junction storm sewers, which discharges to the Colorado River. 2.0 SITE MAP - The SWMP shall include a legible site map(s), showing the entire site, identifying: a) Construction site boundaries; b) All areas of ground surface disturbance; c) Areas of cut and fill; (See Completed forms tab in USMS binder) d) Areas used for storage of building materials, equipment, soil, or waste; e) Locations of all structural BMPs; f) Locations of non-structural BMPs as applicable; and g) Locations of springs, streams, wetlands and other surface waters. Refer to the Master Site Map in the construction office or SWMP and [if utilized the ‘working copies’ with each inspection. 3.0 STORMWATER MANAGEMENT CONTROLS a) SWMP Administrator The site superintendent, field/project engineer, and/or the general foreman will be responsible for implementing the practices outlined within the SWMP. It will be their responsibility to insure the SWMP’s adequacy at all times and to effectively manage potential storm water pollutants 5 throughout the course of construction. Additionally, the SWMP Administrators will be tasked with ensuring the proper implementation, operation, inspection, and maintenance of BMPs across the project site. b) Phased BMP Implementation. The following Tables 1.1 – 1.5 indicate the major activities that are planned to occur during the major phases of construction. NOTE: The following tables are for initial planning and budgeting purposes and as soon as active construction begins, these tables will be superseded by the regularly updated BMP and Pollution Source logs in the SWMP Binder. Upon active construction start, also refer to the Master Site Map and the Working Copy Site Maps for current BMP and Pollution Source locations (See Site Map Section 2.0) Table 1.1 – Phase 1 Est. Start Date: 11/12/12 Construction Activity Est. Finish Date: 11/16/12 Mobilization Best Management Practices (BMPs) Potential Pollutants Erosion Sediment Prep Trailer Area & Install Initial BMPs DSF, SEE, TP EV VTC, EV, SSB CF, Staking (PT), SS Mobilize trailers and equipment. DSF, SEE, TP, SWT, P EV VTC, EV, SSB CF, WM, CNX, SS, SC, SK Operational Table 1.2 – Phase 2 Est. Start Date: 11/19/12 Construction Activity Clear & Grub / Overlot Grading Over-excavation / Structural Fill Foundation Excavation Est. Finish Date: 1/3/13 Clear & Grub, Excavation Potential Pollutants DSF, SEE, TP, SWT, P, S, FD, VEM DSF, SEE, TP, SWT, P, S, FD, VEM DSF, SEE, TP, SWT, P, S, VEM Best Management Practices (BMPs) Erosion Sediment Operational EV VTC, EV, SSB CF, WM, SS, SC, SK EV VTC, EV, SSB CF, WM, SS, SC, SK Dust Repression - Water Trucks EV VTC, EV, SSB CF, WM, SS, SC, SK 6 Table 1.3 Phase 3 Est. Start Date: 12/12/2012 Construction Activity Install Underground Utilities Est. Finish Date: 4/3/2013 Underground Utilities Potential Pollutants DSF, SEE, TP, SWT, P, S, VEM, MSA Best Management Practices (BMPs) Erosion Sediment Operational EV VTC, EV, SSB, IP CF, WM, CNX, SS, SC, SK Table 1.4 – Phase 4 Est. Start Date: 1/3/2013 Construction Activity Drill/Pour Piers, Foundation Walls, SOG Vertical Construction & Impervious Surfaces Potential Pollutants DSF, SEE, TP, SWT, P, S, MSA, CC, CWW Est. Finish Date: 12/26/13 Best Management Practices (BMPs) Erosion Sediment Operational EV VTC, EV, SSB CF, WM, CNX, SS, SC, SK CWA, SSB EV VTC, EV, SSB CF, WM, SS Backfill Walls DSF, SEE, TP, SWT, P, S, MSA Install Steel Structure TP, SWT, MSA CF, WM, CNX, SS, SC, SK Roofing & Roof Drains TP, SWT, MSA CF, WM, CNX, SS, SC, SK Exterior Masonry TP, SWT, P, MSA, MO CF, WM, CNX, SS, SC, SK CWA, SSB Interior Finishes TP, SWT, MSA, CC CF, WM, CNX, SS, SC, SK Install Curb/Gutter & Sidewalks Grade/Prep and Pave Parking Lots DSF, SEE, TP, SWT, P, S, MSA, CC, CWW DSF, SEE, TP, SWT, P, S, MSA, CC EV VTC, EV, SSB, IP CF, WM, CNX, SS, SC, SK CWA, SSB EV VTC, EV, SSB, IP CF, WM, CNX, SS, SC, SK CWA, SSB 7 Table 1.5 – Phase 5 Est. Start Date: 4/23/2013 Est. Finish Date: 9/27/2013 Final Grading & Stabilization Construction Activity Finish Grading Potential Pollutants DSF, SEE, TP, SWT, S Best Management Practices (BMPs) Erosion Sediment Operational CF, WM, CNX, SS, SC, EV EV, SSB, IP SK Install Irrigation System DSF, SEE, TP, SWT, S EV EV, SSB, IP CF, WM, CNX, SS, SC, SK Install Plants & Sod and Permanent Seeding/Mulch DSF, SEE, TP, SWT, S, FN EV, PSM, Sod, Mulch EV, SSB, IP SS, SSB Temporary BMPs will be removed upon Final Stabilization of project c) Identification of Potential Pollutant Sources NOTE: Table 2.0 was created for initial planning and budgeting purposes only and will be superseded upon the start of active construction by the current Master Site Map and Pollution Source Logs in the SWMP Binder All anticipated potential pollutants will be addressed with an individual Pollution Source Log Sheet that can be found in the SWMP Binder. As construction progresses, any new Pollution Sources that are discovered during the course of work that were not anticipated during the planning phase will be added to the current PS Logs in the SWMP Binder. The following pollution sources were evaluated for their impact on this project: Table 2.0 Abbrev. Pollution Source BMPs Utilized CC Construction Chemicals SSB, CNX, SC, SK CWW Concrete Washout Waste CWA, SSB DSF Disturbed Soil - Flatter than 3:1 VTC, IP, SSB, PSM, SS EM Equipment Maintenance & Fueling SK, SC FD Fugitive Dust Dust Suppression (Water Trucks/Hoses) FN Fertilizers & Nutrients SSB 8 MO Masonry Operations – Sand/Cement SSB, SC, CWA MS Material Storage SSB, SC, SK, CNX Petroleum Products SC, SK, CNX Portable Toilets Staking Stockpile SSB, EB SEE Site Entry/Exit VTC, SS SWT Solid Waste / Trash WM P PT S d) Best Management Practices (BMPs) for Stormwater Pollution Prevention The following BMPs were evaluated prior to the start of construction as being potentially necessary to control/treat the pollution sources evaluated in Section 3b and c. Table 3.0 was created for initial planning and budgeting purposes only and upon the start of active construction will be superseded by the BMPs indicated on the Master Site Map and the BMP logs in the SWMP Binder. Each structural and non-structural BMP type located on the Master Site Map will have an individual Log Sheet in the SWMP Binder. BMP Type Logs will provide information about each BMP implemented on the project including narratives on proper installation and maintenance and installation details, as required. 1) Structural Practices: Refer to SWMP Binder 2) Non-Structural Practices: Refer to SWMP Binder Table 3.0 BMP Designation Description - Scheduling/Planning - Training/Meetings Notes Preplanning of stormwater management controls for upcoming construction activities is an important step in the proper management of the site and appropriate adjustments will be made to reduce the negative impact to stormwater quality to the best extent that is practicable. New employees and contractors will be educated on the contents of the SWMP as it applies to them and the importance of pollution prevention for the project. This will be done informally in the field as necessary and may be discussed in routine meetings held on-site. 9 - Weather Monitoring - Dust Suppression / Wind Erosion SS Street Sweeping The weather forecast will be monitored daily as regular preparation for construction activity planning. A log to track actual weather events may be kept as well. Water trucks will be implemented to suppress dust emanating from disturbed areas as needed, until permanent or temporary stabilization BMPs can be employed. Street sweeping will be conducted if tracking of sediment occurs on paved areas. Sweeping will be done at the end of each day, if required, or as soon as weather allows. CNX Connex Box Refer to the BMP Log for more info CWA Concrete Washout Area Refer to the BMP Log & Detail for more info WM Waste Management (Dumpster) Refer to the BMP Log for more info SSB Soil Silt Berm Refer to the BMP Log & Detail for more info EV Existing Vegetation Preservation / Buffer Strip Refer to the BMP Log for more info IP Inlet Protection Refer to the BMP Log & Detail for more info Permanent Seed & Mulch Refer to the BMP Log for more info SC Secondary Containment Refer to the BMP Log & Detail for more info SK Spill Kit Refer to the BMP Log for more info Vehicle Tracking Control Pad Refer to the BMP Log & Detail for more info PSM VTC 3) Materials Handling and Spill Prevention. The following are material management practices that will be used to reduce the risk of spills or other accidental exposure of materials and substances to stormwater runoff. Good Housekeeping: The following good housekeeping practices will be followed onsite during the construction project: 1. An effort will be made to store only enough material required to do the job. 2. All materials stored on site will be stored in a neat, orderly manner in their appropriate containers and protected from weather or within secondary containment. 3. Products will be kept in their original containers with the original manufacturer’s label. 10 4. Substances will not be mixed with one another unless recommended by the manufacturer. 5. Whenever possible, all of a product will be used up before disposing of the container. 6. Manufacturers’ recommendations for proper use will be followed. 7. Any remaining chemicals shall be disposed of according to manufacturers’ recommendations and in accordance with Federal, State and local regulations. 8. The SWMP Administrator will inspect regularly to ensure proper use and disposal of materials onsite. Hazardous Products: These practices are used to reduce the risks associated with hazardous materials. 1. 2. 3. 4. Products will be kept in original containers unless they are not re-sealable. Original labels and material safety data will be retained. Products will be stored under cover If surplus product must be disposed of, manufacturers’ or local and State recommended methods for proper disposal will be followed. Product Specific Practices: Petroleum Products: All onsite vehicles will be informally monitored for leaks and receive regular preventative maintenance to reduce the chance of leakage and encourage safe operations. Petroleum products for vehicle and equipment operation and maintenance will be stored in tightly sealed containers which are clearly labeled. Any asphalt substances used onsite will be applied according to the manufacturer’s recommendations. Leaks occur generally as a result of faulty, old or improperly maintained equipment or storage facilities. If unintentional leaks are detected, the operator will identify and abate the material immediately. For impervious surfaces, an absorbent material will be used to soak up the liquid wastes and then swept up and placed in a contained unit for proper disposal. When leaks are detected on soils, the operator will remove contaminated soils from the earth and place them in a contained unit for proper disposal. Containers used for contaminated materials will be clearly marked and kept from coming into direct contact with storm water. Storage or fueling areas where leaks can occur shall be inspected visually on a regular basis. Efforts taken to abate unintentional leaks and repair faulty equipment should be recorded in the activity log. Unintentional leaks must not be confused with spills and should be identified accordingly. Fertilizers: Fertilizers will be applied only in the minimum amounts recommended by the manufacturer. Once applied, fertilizer will be worked into the soil to limit exposure to storm water. Storage will be in a covered and contained area. The contents of any partially used bags of fertilizer will be transferred to a sealable plastic bin to avoid spills. Soil amendments will be spread and tilled into the soil immediately upon arrival to the site in order to minimize direct contact with storm water runoff. Where soil amendment stock piles are necessary, they will be contained using BMPs such as earthen berms. Paints and Solvents: All containers will be tightly sealed and stored protected from weather, or in secondary containment, when not required for use. Excess paint or 11 solvents will not be discharged into the storm sewer system, but will be properly disposed of according to manufacturer’s instructions and State and local regulations. Concrete wash waste: Any necessary concrete trucks will be allowed to wash their chutes in designated areas on the site. Surplus concrete wash water and drum wash water will be disposed of at an approved off-site landfill and will not be allowed to be discharged at the site. No washout material will be allowed to run off site, and wash out areas will be properly cleaned as necessary. Spill Control Practices: In addition to the good housekeeping and material management practices discussed previously in this plan, the following practices will be followed for spill prevention and cleanup: Manufacturers’ recommended methods for spill cleanup will be clearly posted in the job trailer and site personnel will be made aware of the procedures and the location of the information and cleanup supplies. Materials and equipment necessary for spill cleanup will be kept in the material storage area onsite. Equipment and materials will include but are not be limited to: brooms, dust pans, mops, rags, gloves, goggles, absorbent powder / kitty litter, sand, sawdust, and plastic and metal trash containers specifically for this purpose. The operator will inform the jobsite personnel that if a spill of any size occurs they are to always notify the SWMP manager and, depending on the nature and severity of the spill, the operator will contact the EPA, downstream users and other regulatory agencies. CDPHE requires that any hazardous material spill be reported when any of the following conditions occur: Over 25 gallons of petroleum 5 CCs of mercury Any and all raw sewage releases Any/all State waters impacted If any of the above criteria is met or exceeded, the Colorado Department of Public Health and Environment, Local Emergency Planning committee, downstream users and other agencies (MS4s) will be notified. The CDPHE will be notified by telephone within 24 hours. In addition, written notification describing the spill and the clean up procedures used will be sent to the agencies 5 days following the spill. If a spill does not meet the above criteria, reporting is not mandatory. When any spill occurs: 1) Notify the controlling operator of the site immediately following a hazardous spill. 2) Document the spill and its clean-up procedures whether reporting is required or not. 3) At a minimum document the following: Nature of spill Quantity of spill 12 Date/time spill occurred Agency notification if necessary Clean-up procedures used Daily monitoring (7 days) after clean-up Photographs Interview(s) with any witnesses of the event General guidelines for clean-up procedures: Immediately control or stop the release/spill Mitigate the spill area as needed with a spill prevention kit Obtain approved secondary containers to store any absorbents used Report the spill to the Responsible Person on the jobsite for determination if further reporting is required or if emergency notification is appropriate. WQCD Toll Free 24-hour Env. Emergency Spill Reporting Line: 1-877-518-5608 4) Dedicated Concrete or Asphalt Batch Plants. Batch Plants are not anticipated to be on the project. 5) Vehicle Tracking Control. Refer to Section 3.d. of the SWMP 6) Waste Management and Disposal, Including Concrete Washout. Refer to Section 3.d. of the SWMP. 7) Groundwater and Storm water Dewatering. Refer to Section 1.g. of the SWMP. 4.0 FINAL STABILIZATION To inactivate this permit, a uniform vegetative cover with a density of at least 70 percent of predisturbance levels will first be reached. All disturbed areas (except those portions covered by pavement, structure or landscaping) will be stabilized with BMP’s as indicated on the Master Site Map. Refer to the landscaping plans for details on the seed mix, application rate, and locations. At the completion of the project, when all areas have received final/permanent stabilization measures, all temporary BMPs shall be removed and properly disposed of. If suitable vegetative cover is not adequately established upon completion of all contract responsibilities, the permit may be transferred or reassigned to the Owner of the site following completion of the contracted work. 5.0 INSPECTION AND MAINTENANCE a) Frequency Inspection of the site will occur at a minimum every 7 days and within 24 hours after a storm or snow melt event that causes surface erosion. Inspections may be conducted more frequently as site conditions warrant. If no construction activities will occur following a storm event, such as when the site is temporarily idle over the weekend, post-storm event inspections shall be conducted prior to re- 13 commencing construction activities, but no later than 72 hours following the storm event. The occurrence of any such delayed inspection will be documented in the inspection record and, regardless of any delayed storm event inspections, the time between routine inspections will not exceed 7 days. b) Reduced Inspection Schedule for Completed Areas When portions of the site meet the following criteria, but final stabilization has not been achieved due to a vegetative cover that has not become established, a thorough inspection of the stormwater management system will be conducted at least once every month, and poststorm event inspections will not be conducted. This reduced inspection schedule will only occur if: i) All construction activities that will result in surface ground disturbance are completed; ii) All activities required for final stabilization, in accordance with the SWMP, have been completed, with the exception of the application of seed that has not occurred due to seasonal conditions or the necessity for additional seed application to augment previous efforts; and iii) The SWMP has been amended to indicate those areas that will be inspected in accordance with the reduced schedule allowed for in this paragraph. c) Inspection Scope The construction site perimeter, all disturbed areas, material and/or waste storage areas that are exposed to precipitation, discharge locations, and locations where vehicles access the site will be inspected for evidence of, or the potential for, pollutants leaving the construction site boundaries, entering the stormwater drainage system, or discharging to state waters. All erosion and sediment control practices identified in the SWMP shall be evaluated to ensure that they are maintained and operating correctly. d) Inspection Report/Records A record of inspections will be maintained. Inspection reports will identify any incidents of non-compliance with the terms and conditions of the permit. Inspection records will be retained for three years from expiration or inactivation of permit coverage. Inspection reports will include: i) The inspection date; ii) Name(s) and title(s) of personnel making the inspection; iii) Location(s) of discharges of sediment or other pollutants from the site; iv) Location(s) of BMPs that need to be maintained; v) Location(s) of BMPs that failed to operate as designed or proved inadequate for a particular location; vi) Location(s) where additional BMPs are needed that are not in place at the time of inspection; vii) Deviations from the minimum inspection schedule as noted above; vii) Description of corrective action for items iii, iv, v, and vi, above, dates corrective action(s) taken, and measures taken to prevent future violations, including requisite changes to the SWMP, as necessary; and viii) After adequate corrective action(s) has been taken, or where a report does not identify any incidents requiring corrective action, the report will contain a signed statement indicating the site is in compliance with the permit to the best of the signer’s knowledge and belief. e) Required Actions Following Site Inspections Where site inspections note the need for BMP maintenance activities, BMPs will be maintained in accordance with the SWMP and the permit. Repair, replacement, or installation of new BMPs determined necessary during site inspections to address ineffective or inadequate BMPs will be conducted in accordance with the permit. SWMP updates required as a result of deficiencies in the SWMP noted during site inspections shall be made in accordance with the permit. 14 6.0 STATEMENT OF CERTIFICATION I certify under penalty of law that this document and all attachments were prepared under my direction of supervision in accordance with a system designed to assure that qualified personnel properly gathered and evaluated the information submitted. Based on my inquiry of the person or persons who manage the system, or those persons directly responsible for gathering the information, the information submitted is, to the best of my knowledge and belief, true, accurate, and complete. I am aware that there are significant penalties for submitting false information, including the possibility of fine and imprisonment for knowing violations. Signed_________________________________________ Date_________________ Print name and title_____________________________________________________ 15 Appendix 1 – Pre-existing vegetation photos 16