job profile

advertisement

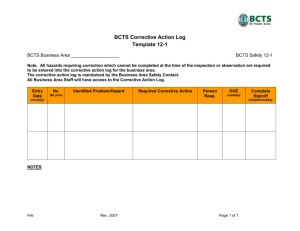

JOB PROFILE JOB TITLE: Operations Manager DEPARTMENT: Operations REPORTING TO: UK Manufacturing Manager MAIN PURPOSE OF JOB: The Operations Manager takes prime responsibility and is the Principal Owner for delivering the product on time in full, to the required quality standards and as efficiently as possible. Reporting to the Manufacturing Manager and working alongside the Engineering and Commercial Operations departments and with the assistance of the Production Leads will coordinate the activities of their manufacturing area. MAIN RESPONSIBILITIES & KEY TASKS: To manage with the Production Leads to ensure product is built and delivered to the appropriate quality standard and On Time in Full. Understand and own STI’s key performance indicators OTIF, Quality, Leadtime. Be able to demonstrate adherence or generate corrective plans to rectify issues. Review OTIF data for all customers monthly with the account managers to ratify and put in place corrective actions as required to ensure targets are met. Monitor and report progress on Corrective Action Trackers. Review Quality data for all customers with QA and Engineering departments monthly to ratify and put in place corrective actions as required to ensure targets are met. Monitor and report progress on Corrective Action Trackers. Verify effectiveness of actions on quality trends. Review Lead-time data for all customers with Account Management monthly to ratify and put in place corrective actions as required to ensure targets are met. Monitor and report on progress on Corrective Action Trackers. Ensure that the Supervisors, Operators, Engineers, Technicians, etc. working in their area are aware of the requirements of the production schedules as agreed with the commercial department. Work in conjunction with the Manufacturing Manager and other department managers to ensure they have planned the resources to enable the supervisors and team leaders to meet the above targets. Ensure that progress against schedule is monitored and reported to all concerned via the weekly Production / Account Manager meeting. Report Company Confidential August 2012 weekly to the Manufacturing Manager output achieved, output still to be achieved and using a risk plan demonstrate actions being taken to alleviate risks to delivery dates. Promote a ‘right-first-time’ attitude to quality, delivery and cost. Ensure that all personnel working in their areas are trained to do the job and fully understand the appropriate procedures. Ensure that the Supervisors, Operators, Technicians, etc. working in their area are trained in accordance with the duties they are required to carry out. Develop people to fill voids and for succession of key staff. Attend Contract Reviews to give delivery dates and any comments regarding the build requirement. Develop capacity plans and identify and manage potential bottlenecks and resource requirements. Set targets for set-up, run time and strip down of each job. Analyse performance against these targets and devise productivity improvement measures. Identify, launch and progress continuous improvement activities in areas such as visual management, productivity, cost, quality, process control, training, work instructions, operator awareness, tooling, wastage, etc Ensure that lean manufacturing principles are applied to all policies and processes. Working with the Business Improvement Manager, actively participate in the promotion and development of the STI lean manufacturing policy. Manage attendance and time keeping using the Promark system. Partner with HR on all people matters relating to operations including workforce planning and resourcing, working conditions, pay & reward, management & development of staff Health and Safety Ensure that all health and safety requirements are met and that staff are provided with appropriate information, training and supervision. People Management and Development Manage and develop direct reports through training and mentoring to create a dynamic and flexible team able to respond to the changing demands of the business Company Confidential August 2012 REPORTING/SUPERVISORY STRUCTURE: Reports directly to Manufacturing Manager. Direct reports include Production Leads QUALIFICATIONS: Degree qualified or equivalent relevant experience Desirable to have an Engineering/Manufacturing discipline as a background KNOWLEDGE AND SKILLS: Demonstrable skills in planning and process-orientated Skilled in people management, able to deliver results by developing the people and achieving the best in class standard Results orientated and able to achieve targets within in a quality compliance based environment Project management skills Change champion – able to drive improvement and change within the manufacturing environment EXPERIENCE: Significant experience in managing a manufacturing/production environment Good understanding of a product realisation process with a specific focus on delivery of the production operations Experience and thorough understanding of Lean Manufacturing principles SPECIAL FEATURES: any “out of norm” features of the job” JOB HOLDER: Signature & Date: MANAGER: Signature & Date: This job profile sets out the main dimensions of the role it describes. It does not identify all individual tasks, which may be expected to change from time to time to meet operational needs. Company Confidential August 2012