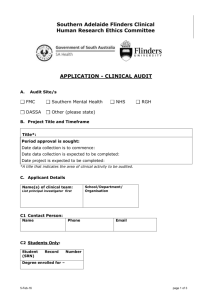

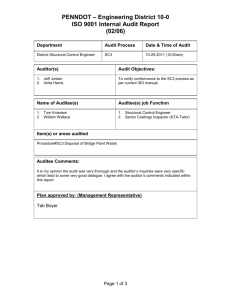

Audit Plan

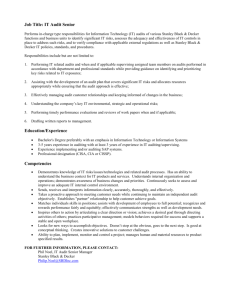

advertisement

Audit Plan Audit Number Company Name Audit Site Scheduled Date of Audit Scheduled Auditor Name Auditor Contact Information I. Purpose: To review the project management, process development, analytical, and manufacturing processes that will be used to make products under Good Manufacturing Practices Confirm applicable policies and standard operating procedures are followed. Ensure procedures and practices comply with cGMP Title 21, parts 210 and 211 and applicable ICH Guidelines. Process development, stability, analytical and manufacturing II. Scope: III. Date of Audit: Confidential Day/Month/Year Page 1 of 2 IV. Agenda List items you expect to review during the audit - for example, Current Organizational Charts, previous FDA/Regulatory Inspections, EIRs, FDA-483’s, Warning Letters etc. Example List: Introduction o Orientation o Company Overview Pharmaceutical Development History FDA/Regulatory Inspections (e.g, Health Canada, EMEA) History EIR’s, FDA-483’s, Warning Letters, including Health Canada, EMEA, Responses Tour of Facility: Materials Handling Area(s), Development Laboratory, Sterile Manufacturing Suite (e.g., Lyophilizer Area), Analytical Laboratories and Stability Chambers Media Fills – How they are handled? History/Results Review of CAPAs Review of Change Change Controls Review of Lyophilizer Validation, including Protocol Calibration and Qualification Package for Vial Crimper Vial Filler Qualification/Validation Package Review of Training Records Closing Discussion o Review of documents o Interviews o Summarized findings o Next steps V. Documents Requested prior to Audit List any documents you would like the audit site to send prior to the audit. Examples List: Equipment List Regulatory Inspection History EIR’s, FDA-483’s, Warning Letters, including Health Canada, EMEA, Responses SOPs o Gowning (1016) o Description of Plant 1 (1010) o Change Control Procedure (1005) o Out-of-Specifications Investigations (1021) o CAPA (1029) o Training (2002) o Cleaning Validation (9001, 9004, 9007, 9008, 1015, 1020) o Monitoring of Particulate Matter, Microorganisms, and Airflow Velocity (1014) Confidential Page 2 of 2