Takaki

advertisement

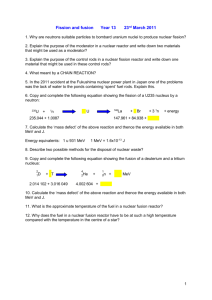

Physics of Fukushima Damaged Reactors and its Preliminary Lessons Naoyuki Takaki Department of Nuclear Engineering, Tokai University 1. The trigger of Fukushima accident The Pacific coast area of eastern Japan was struck by the Tohoku district - off the Pacific Ocean earthquake at 14:46 on March 11, 2011. The magnitude of this earthquake was 9.0. It was the largest one in Japan’s recorded history. This earthquake occurred offshore Miyagi prefecture at a depth of 23.7km where the Pacific plate sinks beneath the North American plate. The size of the source area is 400km north to south x 200km east to west and the seismic intensity is registered more than 6 on the Japanese seismic scale over a wide area (Fig.1). Epicenter Fukushima nuclear power stations Seismic Intensity Fig.1 7 4 6+ 3 62 5+ 1 5- Location of epicenter and seismic intensity Afterwards, tsunamis struck the Pacific coast in a series of seven waves, resulting in the inundation of an area as large as 561km2 and approximately 25,000 people are reported dead or missing. Two nuclear power stations of Tokyo Electric Power Co. (TEPCO) located in this coast area as lustrated in Fig.2 were also struck by the huge tumani waves. At the Fukushima Dai-ichi sites, south one of them, the coming of tsunami with the height of 14 to 15m consequently caused a great deal of damages for three units under operation and for 1 unit which had been shut down for planned maintenance, with the nuclear fuel having been transferred to the spent fuel pool. 1 Fig.2 Nuclear power stations along Pacific coast area of eastern Japan 2. Accident progression 2.1 Station blackout after normal shutdown Table 1 summarizes 3-mode acceleration observed at each plant. Reactor No.2 (built on solid bedrock) suffered the largest horizontal ground acceleration of 550 gals, which is 26 percent stronger than the reactor's design limit, however, three units from 1 to 3 at the Fukushima Dai-ichi sites which were under operation automatically shut down at 14:46 on March 11. Table 1 How large is the ground motion at the Fukushima Dai-ichi plants ? 2 All six external power supply sources were lost because of intense ground motion. This caused the emergency diesel power generators to start up, as expected response according to its design. However, seawater pumps, emergency diesel generators and distribution boards were submerged by the tsunami strike, and all emergency diesel power generators stopped except for one generator in Unit 6 that is an air-cooled type. Thus all AC power supplies were lost except at Unit 6. Since the seawater pumps were submerged, residual heat removal systems to release the residual heat inside the reactor to the seawater and the auxiliary cooling systems to release the heat of various equipments to the seawater lost their functions (Fig.3). Fig.3 2.2 Major root cause of the accident Emergency cooling of the core Therefore core cooling functions not utilizing AC power were put into operation, or, alternately, attempts were made to put them into operation. These were operation of the emergency isolation condenser (IC) in Unit 1, the operation of the reactor core isolation cooling system (RCIC) in Unit 2 and the operation of the RCIC and the high pressure injection system (HPCI) in Unit 3. Here the IC in Unit 1 has a function to cool down the water vapor in the reactor pressure vessel (RPV) during isolation event. The water vapor send to heat exchanger is condensed into water then returned into RPV (Fig.4). Two ICs can remove heat load of 6% of rated power that is almost enough for decay heat removal. The IC pool capacity is designed for 10 hours operation without AC power to makeup water vapor into IC tank. The IC of Unit 1 automatically started up at 14:52 on March 11 and started cooling the reactor, however, it was manually stopped functioning at 15:03 on the same day (before tsunami hit) to keep the cooling speed less than 55 degrees Celsius/hour by following operation manual. 3 •IC Tank capacity is for 10 hours •Operation of valves requires DC power Fig.4 Isolation condenser (IC) The RCIC in Unit 2 and 3 is a system that cools the reactor cores when reactors are isolated from feed water and condenser systems. The water vapor in the RPV sent to RCIC turbine drives pump that injects water either from the condensate storage tank or the pressure suppression pool into RPV (Fig.5). Condensed reactor steam (drained water from RCIC turbine) is discharged to suppression pool. All valves and governor in the turbine pump can be operated by DC power and this RCIC can be operable only for 8 hours. As for Unit 2 and 3, TEPCO manually started up this RCIC just after the earthquake. But the RCIC automatically stopped very soon because of the high water level in the reactors. The RCIC did not work continuously, however they tried to restart RCIC several times after the first trial and finally DC power was lost. •Requires DC power for operation of valves and governor. Fig.5 Reactor core isolation cooling system (RCIC) The HPCI is one of the emergency core cooling system that injects water, with the pump driven by providing the water vapor generated by the decay heat to the turbine. The HPCI in Unit 3 4 automatically started due to the reactor low water level at 12:35 on March 12 and the HPCI stopped at 2:42 on March 13. The reason for this appears to have been a drop in pressure in the reactor. Another probable cause could be water vapor outflow from the HPCI system. HPCI was not activated for Unit 1 and 2 and the reason is not clear at this moment. These core cooling systems that do not utilize AC power supplies stopped functioning thereafter, and were switched to alternative injections of freshwater or sea water by fire extinguishing lines, using fire engine pumps. 2.3 Hydrogen generation Concerning Units 1 to 3 of the Fukushima Dai-ichi NPS, as the situation where water injection to each RPV was impossible to continue for a certain period of time, the nuclear fuel in each reactor core was not covered by water but was exposed, leading to hydrogen generation. Once the rods reach more than 1200 degrees Celsius, the zirconium of the fuel cladding tubes will interact with the water vapor and split the hydrogen from the water by the following chemical reaction. Zr + 2 H2O → ZrO2 + 2 H2 In addition, the fuel cladding tubes were damaged and radioactive materials therein were discharged into the RPV which keeps radioactive materials inside the reactor. Further, these hydrogen and radioactive materials were discharged into the primary containment vessel (PCV) during the depressurization process of the RPV. If the hydrogen released from the reactor core and containment vessel accumulates in sufficient concentrations of 4% or more with 5% of oxygen gas in the air, it can explode. With damaging cladding tube, the core melt was made progress. Part of the melted fuel stayed at the bottom of the RPV. This will be discussed later in more details. 2.4 Venting to save containment vessel Injected water vaporizes after absorbing heat from the nuclear fuel in the RPV. Accordingly, the inner pressure rose in the RPVs which had lost their core cooling functions, and this water vapor leaked through the safety valves into the PCV. Due to this, the inner pressure within the PCVs in Units 1 to 3 rose gradually. TEPCO built new vent pipes extending from the suppression pool and dry well (D/W) to the stacks from 1999 to 2001 as PCV vent facilities during severe accidents as shown in Fig.6. These facilities were installed to bypass the standby gas treatment system (hereinafter referred to as SGTS) so that they can vent the PCV when the pressure is high. The facilities are also provided with a rupture disk in order to prevent malfunction. 5 Fig.6 Venting Facility The PCV vent from the suppression pool is referred to as “wet vent” and vent from dry well is referred to as “dry vent”. By conducting these vent operation, the gases including radioactive isotopes and hydrogen in the PCVs are released into the atmosphere through the ventilation stack. The former wet vent is cleaner and given higher priority. The procedures for operation in severe accidents specify that the chief of emergency response headquarters shall determine whether PCV vent operation should be conducted after core damage. The wet vent shall be conducted when the PCV pressure reaches the maximum operating pressure before core damage or when the pressure is expected to reach about twice as high as the maximum operating pressure after core damage, if residual heat removal system (RHR) is not expected to be recovered. The wet vent shall be conducted if the vent line of the suppression pool is submerged. Because of the total loss of the AC power supply, motor driven valves had to be opened manually for the PCV venting operations. For operation of pneumatically-actuated valves, the pressurized air required for operating such valves could not be assured, and thus a temporary air compressor had to be mounted to assure the pressurized air. For such reasons, the facilities could not be operated in accordance with the documented operation procedures for severe accidents, which caused the PCV venting operation to be delayed. Reducing pressure was necessary to protect the PCV therefore vent operations of PCV wet well was carried out a number of times. Consequently such operations were too late to prevent hydrogen explosion then huge amount of radioactive materials were released into environment. 6 2.5 Hydrogen explosion After the wet well venting of the PCVs, explosions caused by hydrogen which had presumably leaked from the PCV occurred in the upper area of the reactor buildings, ruining the operation floor in the reactor buildings of Units 1 and 3. As a result of these incidents, a lot of radioactive materials were discharged to the atmosphere. The hydrogen gas produced in Unit 1 is estimated to be about 270kg and the concentration of 15%. In the Unit 3, the amount and the concentration of hydrogen seems to be almost double then caused harder explosion (detonation) than that occurred at Unit 1 as shown in Fig.7. Unit 1 Fig.7 Unit 3 Hydrogen explosion at Unit 1 (at 15:36 JST on 12 March) and Unit 3 (at 11:15 JST on 14 March) Following the ruination of the Unit 3 building, an explosion probably caused by hydrogen occurred in the reactor building of Unit 4, ruining its upper area. In Unit 4, all core fuels had been transferred to the spent fuel pool for planned maintenance before the earthquake. Thus damaged fuels stored in the spent fuel pool at Unit 4 were suspected as a source of hydrogen generation. Unit 4 Common Stack From Unit 3 Fig.8 Plausible hydrogen path from Unit 3 to Unit 4 7 The spent fuel pool has about 2 MW heat load that is relatively high because of existence of new fuels but water level is maintained by filling up water from outside. Pool water sample were taken and it has been confirmed that there should be no severe fuel damage. Accordingly, it is considered that hydrogen gas caused explosion at Unit 4 might come from vent line merged with adjacent unit (unit 3). As for Unit 2, it seems that a hydrogen explosion occurred and caused damage at a point presumed to be near the suppression pool. 2.6 Core meltdown The core conditions of Unit 1, 2 and 3 were analyzed by using current limited information with necessary assumption such as diameter of leak hole of PCV to determine a leak rate of water vapor, working condition of cooling system without AC power supply, etc. The results shows that the reactor core of Unit 1 has been significantly damaged after the IC stopped, then the fuels were relocated below or slumped to the lower plenum from the fixed position of the loading, however, most of it is being stably cooled down around there (Fig.9 and Fig.10). Fig.9 Water level of Unit 1 reactor core As for the core of Unit 2, if we assume that the water level could be maintained above the active fuel zone by sufficient water supply with fire pump, there partially exists a molten core pool, but a large part of fuels remains in original range and does not lead to breach of RPV. The reason is that the water injection by RCIC at the early stage was implemented continuously and the period of RCIC suspension was shorter than in the case of Unit 1. Assuming lower water level and larger parts of exposed fuel due to smaller water injection, the damage of the core of Unit 2 could be more serious and breach of RPV is unavoidable. 8 4.7 hours after SCRAM 14.3 hours after SCRAM 5.3 hours after SCRAM Fig.10 15 hours after SCRAM Progression of core melt of Unit 1 The core of Unit 3, there partially exists a molten core pool, but a large part of fuels remains in original range and does not lead to breach of RPV because water injection by RCIC and HPCI at the early stage was implemented continuously and time period of HPCI suspension is shorter than in Unit 1. Assuming lower water level, the damage of the core of Unit 3 could be more serious and breach of RPV is unavoidable. These analyses were performed based on data containing many uncertainties and should be confirmed by detailed investigation after cold shutdown in near future. 2.7 Cooling of spent fuel pool The most urgent task just after the accident at the site, along with recovery of the power supply and the continuation of water injection to reactor vessels, was water injection to the spent fuel pools. In the spent fuel pool in each unit, the water level continued to drop on account of the evaporation of water caused by the heat of the spent fuel in the absence of the pool water cooling system, due to the loss of power supply. Water injection to the spent fuel pool was carried out by the Self-Defense Forces, the Fire and Disaster Management Agency and the National Police Agency, using helicopters and water cannon trucks. Concrete pump trucks were ultimately secured, which led to stable water injection using freshwater from nearby reservoirs after the initial seawater injection. 3. Particularities, lessons and challenges 3.1 Particularities and seriousness of Fukushima accident The clear and essential difference between Fukushima and the past nuclear disasters happened at Chernobyl and TMI is the cause of accident. There is no doubt that the first trigger of Fukushima is 9 a tremendous natural disaster nothing like that Japan has ever experienced in the recorded history. Furthermore the decisive factor is not earthquake itself but tsunami that struck the site about 40 minutes later and destroyed necessary equipments and power supply to cool the reactors and spent fuel pools. Namely this Fukushima accident has the following particularities. It was triggered by a natural disaster; it led to a severe accident accompanied by hydrogen explosion, damages to fuels in cores and spent fuel pools, core melts, damages to RPV and PCV in multiple units, resulting in release of radioactive materials into atmosphere (770 PBq) and the ocean (5 PBq). The rating of INES (International Nuclear and Radiological Event Scale) officially announced on March 11th by NISA (the Nuclear and Industrial Safety Agency) of Japan was only level 3. But it was successively revised to level 4 on March 12th, to level 5 on March 18th and finally to level 7 on April 12th by reflecting amount of released radioactivity and seriousness of accidents relating multiple facilities. To stabilize damaged reactors, bringing the temperature at the base of each reactor vessel to below 100 degree centigrade is a key. The conditions for achieving “cold shutdown” is temporary extended by including leakage termination of radioactive substances from the plant to environment in addition to the original definition in terms of the reactor temperature. TEPCO had planned the milestone of shutdown is no later than January 2012 but it will be slightly moved up owing to improved smooth operation of radioactive water processing facilities. It will take decades to complete the decommissioning plants after removal of melted fuels. • Cooling – Operate the closed circulation system of cores and SF pools to remove the decay heat and cleanup the coolant. • Minimizing residual risks – Nitrogen gas injection – Support SF pool from the bottom of (Unit 4) – Reliability of power supply – Reactor building cover • Cold shutdown • Remove fuels • Decontamination • Decomissioning • Waste disposal Fig. 11 Several months By January 2012 Several decades On-going, near-term and future actions 3.2 Lessons learned However it is only natural the power of natural disaster is far beyond human understanding, TEPCO and the Japanese government are solemnly responsible to ensure the safety of nuclear power 10 palns and to avoid any risk impending to the public. The Fukushima accident revealed some weakness and imperfectness in technological design of nuclear plant and the authorization process. All electric power companies that own nuclear plants had already taken prompt actions to enhance resistance to tsunami disaster by deploying power-supply vehicles, cables, spare pumps etc. according to directions by a minister of METI. These are just temporary actions and more complete measures should be adopted based on lessons learned from this accident. The nuclear emergency response headquarters organized by Japanese government presented 28 lessons which are classified into 5 categories in a report submitted to the IAEA ministerial conference on June 2011. The categories include 1) sufficiency of preventive measures against a severe accident, 2) adequacy of the responses to this severe accident, 3) adequacy of the emergency responses to the nuclear disaster in this accident, 4) robustness of the safety infrastructure established at nuclear power stations and 5) thoroughness in safety culture while summing up all the lessons. Table 2 lists the identified lessons. Table 2 Lessons learned from Fukushima accident (identified by the nuclear emergency response headquarters) 11 3.3 Challenges in front About three-fourth of Japan’s 54 reactors have been shut down by the middle of September 2011 because of planned maintenance, leading to power shortages that could compel nation to save power and result in hurting Japan’s economy. Assuming no reactor can be restarted, Japan may have no nuclear reactors running by May 2012. To prevent this situation, the government decided to conduct stress test consisting of two steps. The first step targets reactors which have already completed planned maintenance and are ready for restart. This will assess resistance to severe earthquakes and other events more extreme than those for which they were designed. If reactors pass the first stage of the two-step, they would be able to restart, while all units would be subjected to more comprehensive tests in a second stage. Under Japan's previous energy plan, prior to the Fukushima disaster, nuclear power had been set to meet more than half of electricity demand by 2030, up from current share of about one-third. Needless to say, obtaining public acceptance is key to restart nuclear reactors but public opinion is generally united in reducing nuclear plants, instead of increasing them. Just after the earthquake, social response seemed to be relatively comprehensive or patient to the nuclear accident, then recently, public increases distrust to nuclear industry, utility company and government while enduring their unrest life brought by the accident. Fig.12 Social response to nuclear industry after Fukushima accident As of August 2011, tens of thousands of residents left the Fukushima prefecture as they feared the health effects of radiation. Most of them intend to avoid their children being exposed to radiation even if the additional radiation dose is generally comparable to the background dose. Although this may be an extreme instance, major part of public equally has more negative impression to nuclear energy than before. Some of them affirm that they are ready to tolerate 12 decelerated economy and worse quality of life with higher energy cost so as to abandon national nuclear energy policy. Generally speaking, top two grounds why public oppose to nuclear energy have been “safety” and ”radioactive waste” regardless of countries. Long lasting radioactivity of nuclear waste as illustrated in Fig.13 is hardly acceptable to public because they consider that it may harm their descendant and imposing problems arising from current generation to future innocent generation is not ethically allowed. The Fukushima accident realistically gives fears of radioactivity, so that Japanese public enhanced their concerns more about potential risk and existence of radioactive material being close area to their life. They noticed that nuclear reactor in operation (and attached spent fuel pool) contains huge amount of radioactivity that is continuously generated therein (Fig.13) and citizens have been forced to live in the vicinity of it. They also learned that the multi-barrier to confine radioactivity in the system can be broken. Fig.13 Radioactivity existed above the ground and buried long term radioactivity “Risk-free world” never exists. Any kinds of modern life involve many kinds of risk to a certain extent ascribed from technologies. Principally, choice of energy source must be made by the balance between risk and benefit. The energy policy should be politically judged based on both scientific data and social factors. Before restarting current nuclear plants and to develop future nuclear system, these concepts must be reexamined. 4. Concluding remarks 13 The Fukushima accident has still been imposing various types of difficulties on daily life of citizens, foods, energy supply, industries, economy etc. of Japan and it simultaneously posing messages to nuclear engineers as partly shown in the last chapter. Through examining the accident with limited determinations of the cause and the current status of the plant, it can be said that the following points should be reviewed and reflected to the design of future nuclear reactors; proper definition of design based event (DBE) to limit the probability of large scale release of radioactive materials by revising the external event to be considered (less probable but high risk events such as huge tsunami, volcanic eruptions, intentional attack by terrorism etc.), more independent and redundant safety system to ensure power supply and cooling functions (ex. distributed arrangement of diesel generators and electrical distribution boards, preparation of various heat sink, coolant injection system driven by gravity etc.), optimized combination of passive safety system with active system that are functional for removing the decay heat even in case of station blackout to secure extended time period enough for necessary accident management. In general, failure is a stepping stone to success, it is however said that it may not be the case for nuclear technology due to the seriousness, hugeness and irreparability of its impact. The Fukushima accident certainly imposed immeasurable hardship and damages on people especially living in east coast of Japan. It is urgently needed to implement radical review for national nuclear energy policy, validity of authorization procedure and related laws and the nature of utilities. If an opportunity to revive was given to nuclear utilization, nuclear plants would become more robust energy source with strengthened safety for natural disaster and other external event. The emerged nuclear power will contribute to power the sustainable world for centuries without emission of greenhouse gas. To realize this, opened and fair discussions on the various energy sources and their realistic deployment strategy should be made again and again. Reference: Report of the Japanese Government to the IAEA Ministerial Conference on Nuclear Safety - The Accident at TEPCO’s Fukushima Nuclear Power Stations -, Nuclear Emergency Response Headquarters, Government of Japan June 2011 Akira Omoto, Fukushima Accident : An overview, Presentation at prenaly session of ICAPP2011, Nice 14