DENTURE LINING MATERIALS - Rawal College Of Dentistry

advertisement

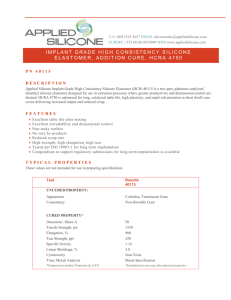

By, Head of Department Dr Khawaja Rashid Hassan Rawal college of Dentistry Islamabad 1 In cases where fitting surfaces of acrylic dentures needs replacement to improve the fit of the denture. Classified into 3 main groups 1. Hard reline materials. 2. Tissue conditioners. 3. Soft lining materials. 2 Chair side relining technique is used. Divided into 2 types. Both types are categorized as auto polymerizable resins. Both types polymerize easily at mouth or room temperature. 3 TYPE 1 POWDER LIQUID POLYMER BEADS POLYMETHYLMETHACRYLATE INITIATOR BENZOYL PEROXIDE PIGMENTS INORGANIC SALTS MONOMER METHYLMETHACRYLATE PLASTICIZER Di-n-butylphthalate CHEMICAL ACTIVATOR TERTIARY AMINE 4 TYPE 2 POWDER LIQUID POLYMER BEADS POLYETHYLMETHACRYLATE INITIATOR BENZOYL PEROXIDE PIGMENTS INORGANIC SALTS MONOMER BUTYLMETHACRYLATE CHEMICAL ACTIVATOR TERTIATY AMINE 5 MANIPULATION: Grinding away some of the hard surface of acrylic base. Powder and liquid are mixed. Applied over the fitting surface of the acrylic base. Seated into the patient’s mouth. Closed mouth technique is used. Not allowed to remain in the patient ‘s mouth throughout setting. 6 1. 2. 3. 4. 5. PROPERTIES: Direct contact with the oral tissues is a disadvantage. Methyl methacrylate in the monomer may cause allergic reaction. Low values of glass transition temperature (Tg) in both type 1 and type 2 materials. May become porous due to air entrapment during mixing. Operator has little control over the thickness of the material. 7 Soft denture liners. Applied to the fitting surface of the denture. Provides cushion to the fitting surface. Plastic flow continues for 24-36 hours after mixing. Several applications in denture works. 8 Often applied to the dentures of the patients undergone surgery. In case of immediate dentures, Addition of the tooth into the denture base that needs to be extracted. Can be used as functional impression material. 9 COMPOSITION POWDER POLYMER BEADS POLYETHYMETHACRYLATE LIQUID SOLVENT ETHYL ALCOHOL PLASTICIZER BUTYLPHTHALYL BUTYLGLYCOLATE 10 COMPOSITION Amount of solvent and plasticizer is very crucial. 7.5% - 40% of liquid contains alcohol. Powder may be pigmented or unpigmented. 11 MANIPULATION On mixing powder and liquid, physical process occurs. Smaller polymeric beads get dissolved and larger beads swell up on absorbing solvent. Final set material is gel-like. High methacrylate, ethyl methacrylate, plasticizer and solvent gives softness. Normally denture and patient’s soft tissues are inspected after 2-3 days. 12 PROPERTIES: Initially very soft and Viscoelastic. Undergo permanent deformation under even small load. Material do not remain permanently soft. Time taken for the material to become hard and loose the cushioning effect varies from days to a couple of weeks. Conditioner should be replaced after 2- 3 days till the tissue has healed properly. 13 Can be sub divided into a) Temporary soft lining materials. b) Permanent soft lining materials. 14 TEMPORARY SOFT LINING MATERIALS: Almost similar to tissue conditioners. Supplied as powder liquid formulation. Composition and manipulation same as tissue conditioners. Retain their softness for longer duration.( upto a month or two) Selection of denture cleanser is very crucial for temporary soft liners. 15 PERMANENT SOFT LINING MATERIALS: Commonly used in patients that cannot tolerate a hard base. In patients with thin mandibular mucosa. These materials should remain permanently soft for the life time of the denture. Elasticity of these materials is very important. 16 AVAILABLE 1. ACRYLIC: Heat cure. Cold cure. 2. SILICONE: Heat cure. Cold cure. MATERIALS: Condensation. Addition. 3. POLYPHOSPHAZINE: 17 Heat cure acrylic is in powder liquid formulation. Powder consist of poly ethyl or poly butyl methacrylate. Liquid consists of butyl methacrylate and plasticizer. Dough is formed which is then heat treated. 18 Heat cure silicone is used in the same way as heat cue acrylic. Presented in a single paste formulation. Paste consist of poly di methylsiloxane polymer. The 2 cold cure silicone elastomers are similar to the silicone elastomers used as impression materials. Cold curing silicones are cured at room temperature. 19 POLYPHOSPHAZINE: Supplied in sheet form. Polymerize by heat cure. Curing cycle can be, 74°C for 8 hours. OR 74 °C for 2½ hours followed by 100 °C for 30 minutes. 20 PROPERTIES: All types are soft and give an adequate cushioning effect. Cushioning effect depends upon the thickness of material. 2-3 mm is sufficient for adequate cushioning effect. Harden through loss of alcohol and leaching of plasticizer. Adequate bond with the denture base. Denture cleansers effect the soft liners. 21 22 . THANKYOU QUESTIONS ???