BRIGHT ACID COPPER UNICOPPER AC 380

advertisement

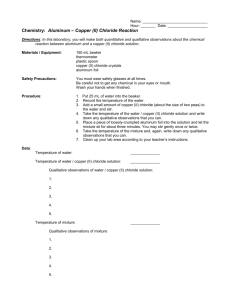

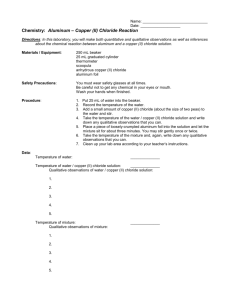

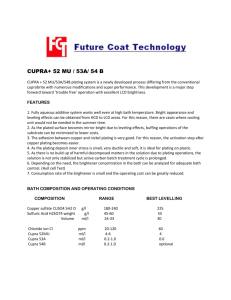

BRIGHT ACID COPPER UNICOPPER AC 380 PHYSICAL PROPERTIES: UNICOPPER AC 381: Clear colourless Liquid. UNICOPPER AC 382: Yellowish Liquid. DESCRIPTION: The UNICOPPER AC 380 process produces extremely bright copper deposits from an acid sulphate bath. It shows excellent levelling, coupled with good throwing power. Copper deposits obtained from UNICOPPER AC 380 are ductile, give good corrosion resistance and exhibit no pitting. UNICOPPER AC 380 process is easy to operate and can be used over steel, zinc diecastings, after required pre-treatment(see below), and in "plating on Plastics". It is very economical to operate due to its low operating temperature, its versatility and its simple effluent treatment. UNICOPPER 380 contains no colour dye. EQUIPMENT: Tanks and filtration Tanks should be rubber lined steel tanks or other suitable plastic tanks. Tanks should be equipped with mechanical agitation or air lines. Air must be free of oil. Continuous filtration is a pre-requisite for successful plating. The back wash type filter is recommended for this operation. Heating and cooling facilities should also be available. Anodes The UNICOPPER AC 380 Process requires copper anodes with a phosphorous content of 0.02 - 0.06%. Cast anodes are generally used but sheets, granules or chips are also suitable. The latter are used in connection with titanium baskets. Before copper anodes are placed in the tank they should be cleaned and any mill coating should have been removed by way of sand blasting. Soon after copper anodes have been placed in operation, hey should be covered with a dark to black coating. This indicated that they are working properly. If so desirable, anode bags can be used. The recommended material is polypropylene. OPERATING DATA: MAKE-UP Copper Sulphate x 5H O ² Sulphuric Acid Conc. c.p. Chloride tolerance H.Donsbach Rev 1.1 RANGE OPTIMUM 180 - 220 g/l 60 - 90 g/l 70 - 300 mg/l 200 g/l 70 g/l 150 mg/l 08.11.2002 1/4 UNICOPPER AC 381 Brightener UNICOPPER AC 382 Basic Brightener 1 - 3 ml/l 2 ml/l 3 - 6 ml/l 4 ml/l WORKING CONDITIONS: Cathode Current Density 1,0 - 6 A/dm² Anode Current Density 0,5 - 2,5 A/dm² Voltage 1,5 - 6 Volts Current Efficiency approx. 100% Temperature 20 - 50° C MAKE UP OF A UNICOPPER AC 380 ACID COPPER SOLUTION: Dissolve required amount of copper sulphate in hot de-mineralised water. This water should not contain more than 300 mg Cl- /liter. Start continuous filtration with small amounts of activated carbon, washed onto the filter. Slowly, add the required amount of Sulphuric Acid to the solution and fill up the desired level with water. Cool to operating temperature, remove activated carbon from the filter and add required amounts of UNICOPPER AC - 380 addition agents. Dummying for approximately two hours at 0.5 A/dm² will remove any trace amounts of foreign metals. PRE-AND POST-TREATMENT OF PARTS: Steel Parts Parts to be plated should be thoroughly cleaned in a soak cleaner, followed by an electrolytic cleaner, acid dip, copper or nickel strike, and acid dip. Water rinses are placed between each step. Zinc Die-Castings Cleaning cycle same as above. Copper strike or alkaline Nickel to a thickness of 3 - 5 microns. H.Donsbach Rev 1.1 08.11.2002 2/4 CONSUMPTION OF UNICOPPER AC 380 ADDITION AGENTS per 10.000 Ah at normal operation 800 – 1200 ml 500 – 800 ml UNICOPPER AC 381 Brightener UNICOPPER AC 382 Basic Brightener If there is no improvement-effect of the quality by adding the additives, please check Chloride content. GENERAL INFORMATION: Proper racking of parts is of utmost importance. Care should be taken that parts do not shade each other. From time to time steel or zinc die-cast parts may fall into the plating solution. We recommend to remove these parts immediately, so that they will not contaminate the plating solution. Temperature Though the UNICOPPER AC 380 process is very tolerant to temperature, it is advisable to stay within specified limits. High temperatures will reduce overall brightness and increase brightener consumption. Low temperatures may cause anode polarisation, burning in high current density areas. Copper Content Copper content of the plating solution should be determined weekly and should be kept within the recommended range. If the metal content of the bath drops rapidly without apparent reason, anode area should be increased. This can be done by hanging extra copper anodes into the plating solution. Sulphuric Acid Content A sulphuric acid determination should be run in connection with the weekly copper analysis. Sulphuric acid should not go above 80 g/l since this would reduce the copper metal solubility in the solution. Chloride Content Chloride content must be kept within the specified limits. An excess of chloride will reduce the levelling properties of the UNICOPPER AC 380 process. Lack of chloride will reduce the degree of brightness. H.Donsbach Rev 1.1 08.11.2002 3/4 Correction: Lack of chloride: 2,5 ml chemically pure Hydrochloric Acid contains 1 g of chlorid ions. Excess of chloride: 4,5 g silver sulphate will precipitate 1 g of chloride ions. Addition Agents Addition agents should be added according to the ampere-hours plated. It is, however, recommended to check the content of addition agents in a Hull Cell plating test. This is done by plating a brass panel at 2 Amperes for 10 minutes in the copper solution to be tested. This panel is then compared to a standard panel, which was plated in a copper bath at optimum conditions. Using the information contained under hereunder, it should be easy to determine which addition agent is lacking or in excess. Addition agents must be kept in a dry place, at room temperature (18 - 30°C) to avoid their crystallisation or evaporation. REMOVAL OF CONTAMINATION: Activated Carbon From time to time it is recommended to make an activated carbon treatment in order to remove organic contaminations caused by drag-in or de-composition of addition agents. Activated carbon is added at a rate of 0,5 to 2,0 kg per 100 l plating solution, depending on the degree of contamination. Activated carbon is added to the solution in a separate tank, stirred for two hours, allowed to settle and filtered back into the plating tank. It is important that no carbon is carried over into the plating tank, since this can lead to rough deposits. SAFETY PRECAUTIONS: see Material Safety Data Sheet GUARANTEE: Above instructions and recommendations are the result of intensive testing and shop experiences. They are for your information, only. Our guarantee extends to the continuous quality of our products as they leave our factory and not to their usage in the field, which is a factor beyond the control of a supplier. H.Donsbach Rev 1.1 08.11.2002 4/4